Robinson R66: Triple crown

Robinson Helicopter scores a third win with the turbine-powered R66

“Affordable” is not a word that is often associated with helicopters. However, for one aeronautical engineer, it is a tenet of his design philosophy. That engineer is Frank Robinson, and affordability quickly follows excellence in safety and engineering.

In the early 1970s Robinson set out to design and manufacture an affordable personal helicopter—the R22. The cost-effectiveness of this aircraft caused an unexpected explosion in helicopter flight training. Reading market needs, Robinson Helicopter followed up with the wildly successful four-place R44, a machine that eventually overtook the R22 in number of units produced. Now with even more engineering maturity and market wisdom, the company is poised for a third bull’s-eye.

In March 2007, Robinson Helicopter announced development of a five-place, single-engine turbine-powered helicopter dubbed the R66. Even though Robinson had not set a price, many in the industry believed the R66 spelled danger for rival Bell Helicopter’s iconic 206B JetRanger. Many helicopter pilots built their turbine experience in the Bell 206B. Introduced in 1966, the 206B has enjoyed a long, successful life. Then, in January 2008, Bell announced that it was ceasing production of the 206B, citing the R66 as one reason.

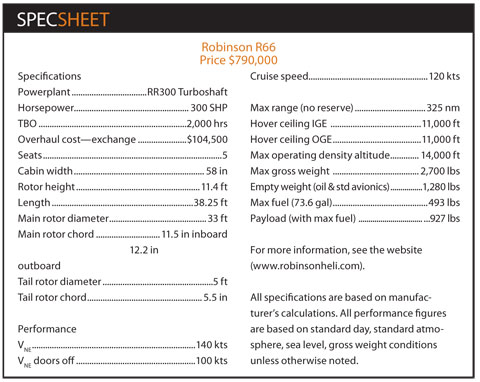

However, according to Kurt Robinson, Robinson’s new president and CEO (Frank Robinson retired August 10, 2010), the intent was not to compete head to head with the Bell 206B, but to create a new market—that being a five-place turbine helicopter for less than $1 million (the actual base price is $790,000). The R66 will do many of the jobs the Bell 206B does, but for a lot less money. Unlike most major helicopter manufacturers, Robinson has built helicopters only for the civilian market—one reason why affordability is key.

The R66 is powered by a Rolls-Royce RR300 (model number 250-C300/A1), a new engine based on the proven 250-series engine (the same engine used in the 206B). It is mounted behind the transmission deck at a 37-degree angle, providing easy access for maintenance. The engine produces 300 shaft horsepower and is derated to 270 shaft horsepower for a five-minute takeoff rating and 224 shaft horsepower for maximum continuous operation.

As Kurt Robinson explains, “The decision to use a turbine engine really had nothing to do with reliability. Data has shown the Lycoming O-540 installed in the R44 to be extremely reliable.” It seems Lycoming would agree, as the company raised the TBO of the piston engine to 2,200 hours only for those installed in Robinson helicopters. The reason for a turbine was to capture a market that required improved performance at high altitude, better power-to-weight ratio, and the use of jet fuel because of the limited availability of avgas in some parts of the world.

First flight

Robinson’s chief pilot, Doug Tompkins, did the experimental test flying for the R66. As we walked around the helicopter, Tompkins pointed out the differences between the R44 and the R66. One noticeable change is the sleeker profile; the door windows sweep down to line up with the lower windshield. The bigger door windows and windshield provide nice visibility. The R66 is eight inches taller than the R44, and its cabin is eight inches wider. A common observation about the R44 is a lack of baggage space. Robinson took note, and the R66 has a JetRanger-style baggage compartment located under the transmission deck. It can hold 300 pounds—and one design objective was for it to be large enough to carry two sets of golf clubs.

Robinson’s chief pilot, Doug Tompkins, did the experimental test flying for the R66. As we walked around the helicopter, Tompkins pointed out the differences between the R44 and the R66. One noticeable change is the sleeker profile; the door windows sweep down to line up with the lower windshield. The bigger door windows and windshield provide nice visibility. The R66 is eight inches taller than the R44, and its cabin is eight inches wider. A common observation about the R44 is a lack of baggage space. Robinson took note, and the R66 has a JetRanger-style baggage compartment located under the transmission deck. It can hold 300 pounds—and one design objective was for it to be large enough to carry two sets of golf clubs.

We opened the cowlings to check fluid levels and drive-train components. One innovative feature is small LED lights that illuminate the sight gauges. Opening the inspection cowlings on the left side of the helicopter reveal a series of steps and handholds that allow the pilot to climb up to inspect the rotor head. The R66 has the same low-maintenance teetering rotor head as the R44, only bigger. Bell 206B operators who have to replace the TT (tension torsion) straps in the rotor head every 1,200 hours or two years (whatever comes first) will appreciate the cost savings. A small access door on the left side houses the refueling port, positioned there as part of Robinson’s quest for low parasite drag on the fuselage. Additionally, because the R44 and R66 look similar, a completely different cap was used to help avoid misfueling.

The wider cabin becomes apparent once seated inside the cockpit. The R66 will be comfortable for larger-framed pilots and is actually 10 inches wider than the Bell 206B. The extra room allows the pedals to be moved a little farther apart, making for a larger feel as well. Robinson kept the T-bar cyclic flight control. Not only does this add to the ease of transitioning from the R44, but it is very comfortable in flight. “The T-bar cyclic fits the company’s design philosophy of keeping things simple and highly functional,” Tompkins points out. “With more than 9,000 R22s and R44s in operation around the world and with such a high concentration of those in the training market [military excluded], virtually all civilian pilots learn on the T-bar.” Love it or hate it, it’s here to stay—and if history is a good predictor of Robinson sales, then the T-bar cyclic might become more prevalent than a conventional control in light helicopters.

The instrument panel contains the typical turbine helicopter gauges: N 1 (gas producer rpm), MGT (measured gas temperature, also known as turbine outlet temperature), and torque. However, a few systems work a little differently than other light turbines. The key switch is labeled Igniter and has two positions: Off and Enable. This allows motoring the starter without firing the igniters—handy for maintenance. In order to do this in the Bell 206B, the igniter circuit breaker on the overhead panel must be pulled. Circuit breakers are not meant to be used as switches because it could lead to premature failure of the breaker—Frank didn’t like that. Directly below the igniter switch is a push/pull fuel cutoff control, exactly like the R44. There is a collective-mounted throttle that goes from idle to full open; there is no closed position. At the end of the collective are the starter button and a rocker switch to beep the N 2 (engine output shaft speed) rpm up and down.

Starting is simple—igniter switch to Enable; press and release the Start button (it’s latched, so no need to hold it down); at 15 percent N 1 push the fuel control in and monitor engine lightoff, MGT, and acceleration. At 65- to 67-percent N 1 the starter disengages and the generator is switched on. In the event the MGT gets too hot, pull the fuel control back out to cut off fuel, and the starter will automatically continue pulling in cool air. To disengage the starter, turn the igniter switch to Off. When the igniter is in the Off position the start button’s latching function is disabled. During the one-minute warm-up, I checked the engine anti-ice, hydraulic system, warning lights, and low rotor rpm horn. Then I rolled the throttle to open and adjusted the rpm to 100 percent with the beep switch.

Picking the R66 up to a hover, the hydraulically boosted controls are smooth, and it feels a little bigger and a little heavier than the R44—which it is. Performing pedal turns made it obvious the R66 inherited the strong and crisp tail rotor control of the R44. Of course, it would have been a surprise to find a weak tail rotor on a Robinson product—Frank’s area of expertise has always been tail rotor design. After Tompkins endured our prolonged spinning around from my fascination with the pedal response, we were ready to depart.

That turbine difference

One major advantage of a turbine engine over a piston is high-altitude performance. Overcast skies restricted our altitude to less than 4,000 feet, not even close to the R66’s maximum operating density altitude of 14,000 feet. To get an idea of the helicopter’s available power Tompkins suggested pulling 100 percent torque as we were climbing out. I started raising the collective and before I got to 90 percent torque the VSI was pegged at 2,000 fpm. I paused for a second to try and figure out how fast we were climbing and Tompkins said, “Keep going”—at 100 percent, the climb felt more like a turbojet airplane. With Tompkins, full fuel, and me, we were 550 pounds under gross weight. Lots of power, for sure, but I thought I would compare OGE (out of ground effect) hover charts, too. At max gross weight at plus-20 degrees C the Bell 206B’s OGE hover ceiling is 3,700 feet. The R66 in the same situation is 7,700 feet. The R44 Raven II (with only a 700-pound payload with full fuel) comes in at 2,800 feet.

At first it might not seem a fair comparison because the R66’s maximum gross weight is 2,700 pounds, 500 pounds lighter than the Bell 206B at 3,200 pounds. However, the basic empty weight of the R66 is also lighter at 1,280 pounds, versus 1,713 pounds for the Bell 206B. Adding 3.2 hours of fuel (full fuel for the R66) to both aircraft (the Bell 206B can hold 3.5 hours) gives identical payloads of 925 pounds. If you fuel the Bell 206B to maximum fuel, payload is reduced by 50 pounds.

At first it might not seem a fair comparison because the R66’s maximum gross weight is 2,700 pounds, 500 pounds lighter than the Bell 206B at 3,200 pounds. However, the basic empty weight of the R66 is also lighter at 1,280 pounds, versus 1,713 pounds for the Bell 206B. Adding 3.2 hours of fuel (full fuel for the R66) to both aircraft (the Bell 206B can hold 3.5 hours) gives identical payloads of 925 pounds. If you fuel the Bell 206B to maximum fuel, payload is reduced by 50 pounds.

With FAA certification expected on October 25, the R66 was still in the Experimental category we had to fly a specific route to an area where we could practice in-flight maneuvers. Having spent a lot of time hovering out of ground effect in both the Bell 206B and the R44, I was ready to try it in the R66. I brought it to a hover at 1,000 feet agl, holding only 74 percent torque. A 360-degree pedal turn was a breeze and again, the strong tail rotor was apparent. From the hover, I lowered the nose to start accelerating and the R66 quickly gained speed. Reaching its V NE of 140 knots (100 knots with doors off) there were no surprises as the R66 felt solid. Another hallmark of Robinson’s engineering is low parasitic drag, and the R66 is no different.

After some time flying around Palos Verdes to get really comfortable with the helicopter we headed back to the Torrance airport for some emergency maneuvers. First was a hydraulics-off landing to the runway. Tompkins said a run-on landing is recommended, but the helicopter can also hover without hydraulic boost. The hydraulic switch is a small toggle switch located on the cyclic control. I turned the boost off and felt an immediate increase in control forces. Slowing to 60 or 70 knots helps keep the control forces down and made lining up for a shallow approach quite easy. Once over the runway, I started slowing to a hover. I found the R66 with hydraulics off to be more sensitive in pitch than roll, but easily controllable. From a hover, I started moving forward to slide the helicopter on the runway. Not my prettiest landing, but safe and controlled.

Next was my favorite: autorotations. First was a straight-in, and Tompkins explained that the best way to enter the auto is to lower the collective while rolling off the throttle. The engine and rotor needles split nicely as the turbine spooled down. I had to raise a little collective to keep the rotor rpm at 100 percent and slowed the helicopter to 70 knots. I started my flare at about 75 feet and leveled out slightly high (at least that was what I thought) but with plenty of pitch for a nice touchdown. When I told Tompkins I thought I was a little high in the flare, he said, “No, you can flare higher than that.” After really enjoying 180-degree and out-of-ground-effect hovering autorotations to a full touchdown, I wanted to try a power recovery auto. Tompkins said, “No need to bring the power in too early; just roll the throttle up in the flare.” I was a little nervous because I normally bring a turbine engine back online prior to the flare. During the flare, as instructed, I brought the power back in and the needles joined smoothly and the torque remained well within limits. According to the flight manual, best glide configuration is 90 knots airspeed and 90 percent rotor rpm, which gives the R66 about one nautical mile per 1,100 feet of altitude.

At this point I had been doing all the flying so I asked Tompkins if he wanted to fly. “Not unless there is something you would like me to demonstrate,” he replied. I was looking for a break, so I asked, “How about an auto?” Tompkins took the controls and did a 180-degree autorotation, which looked pretty much like mine except he flared even higher. After a smooth touchdown he said, “I thought I’d show you how much higher you can flare the R66.” Although the rotor diameter is the same as the R44’s, the slightly wider chord provided more margin in the touch down.

We finished up with some hovering autos in a grass area in front of the factory. To give the wider blades another test I tried one from 10 feet and the R66 performed well with collective pitch to spare. I hover taxied back to the ramp. Shutdown was simple—a two-minute engine cool down followed by pulling the fuel cutoff and monitoring the MGT.

Robinson puts the direct operating cost (fuel, reserve for overhaul, and scheduled/unscheduled maintenance) at $250 per hour. Current airframe and engine TBO is 2,000 hours.

With air conditioning available early next year, the R66 will be able to perform the vast majority of jobs now being done by the Bell 206B with probably one exception: Three NFL linebackers simply will not fit in the rear cabin. The R66’s compact rear cabin was a design trade-off. In order to keep the cabin unobstructed, engineering limitations prevented a bigger increase in cabin length. Like the R44, Robinson plans to offer a turnkey police helicopter and Newscopter.

Bell introduced a stretch version of the 206B called the 206L (LongRanger). Will Robinson do the same? Kurt Robinson is not saying; his only comment was, “Right now we are focused on getting the R66 to our customers and designing and building the future upgrades our customers tell us they need. It is hard to say what our next major design will be; however, it will also come from what our customers tell us they need.” That statement exemplifies Robinson Helicopter and has brought the company from humble beginnings in Frank’s house to the world’s most prolific manufacturer of civilian helicopters.

Tim McAdams is the director of business development for SKY Helicopters in Dallas. He also writes the AOPA Hover Power blog. Photography by Chad Slattery