Fueling Process

SAFETY SPOTLIGHT: Fuel Management

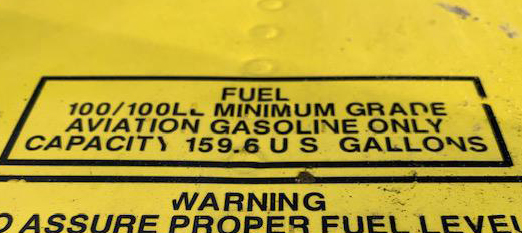

Fixed base operators (FBOs) that provide fuel generally have line personnel to dispense it. However, airports may also have self-service fuel facilities. In either case, make sure you receive the proper fuel grade and quantity.

Fuel Grades

Know what’s in your tanks: Verify they have been filled with the proper fuel grade, and make sure no water or contaminants have gotten into them.

- Avgas—Early airplanes used automobile, motorcycle, or tractor engines, and low octane fuel was sufficient to power them. But low octane fuel burned too easily in modern high compression engines, resulting in combustion before the spark plug fired. To prevent this damaging preignition or detonation, lead was added to avgas to slow down the combustion process. Avgas today is known as 100LL (low lead), has a light blue tint, and evaporates quickly.

- Jet Fuel—Like kerosene, it burns at much higher temperatures than gasoline engines can withstand. Because jet fuel will damage or destroy gasoline engines, there are safety precautions to prevent misfueling, such as color-coded wing decals and jet fuel nozzles shaped like a duck’s bill that will not fit into standard avgas fuel tanks. Jet fuel is clear or yellowish in color, does not evaporate as quickly as avgas, and has a distinctive, heavier, kerosene odor.

- Autogas—If an Inspection Authorized (IA) mechanic has completed aircraft modifications mandated by a Supplemental Type Certificate (STC), an aircraft can be fueled with 80- or 100-grade automobile gasoline (autogas), depending upon the type of certification. However, while some aircraft engines can use autogas, there are several reasons why others may not. Compared to Avgas:

- It has looser manufacturing specifications and quality control is less stringent, so quality and performance vary widely.

- Because of less careful handling, the risk of contamination is greater.

- Physical and chemical property differences can lead to poor fuel distribution, poor anti-knock properties, and excessive motor oil dilution.

- It is less stable and more likely to gum up.

- It is more volatile and therefore more prone to excess vaporization, vapor lock, and carburetor icing.

Avoid Misfueling

The consequences of introducing an improper fuel into an aircraft’s tanks range from the benign (fuel system drainage) to the expensive (engine replacement) to the disastrous (engine failure shortly after takeoff). Given simple precautions, all are easily preventable, starting with pilot oversight during the fueling process.

Many pilots think that sumping the tanks will reveal a fueling error. However, that may not always be true. The blending of two different fuels within the tank can mask the color and smell distinctions that would normally signify a problem. Also mistaken is the assumption that a misfueled engine will fail to start, or will run poorly. In many cases, the engine may seem to run normally for quite some time—long enough to lure a pilot into a false sense of well-being.

If you have any doubts about the type of fuel in your tanks, do not depart.Fueling Strategies

Ordering fuel is not a complicated process. But to avoid misfueling, be present every time your aircraft is fueled and observe these simple guidelines.

Fuel grade and quantity—Specifically state the fuel grade and quantity (e.g., “Please top off both tanks with 100LL.”) or use fuel order forms, which are often color-coded for positive identification. The color-coding is standardized: Avgas = RED; Jet = BLACK. Get a read-back of your fuel order from the FBO employee who took it. Match the fuel truck or fuel island color-coding with the color of the wing fueling decal and confirm the fuel grade again with the line service professional. Actively observe the fueling process. If something doesn’t seem right, speak up immediately.

Fuel grade and quantity—Specifically state the fuel grade and quantity (e.g., “Please top off both tanks with 100LL.”) or use fuel order forms, which are often color-coded for positive identification. The color-coding is standardized: Avgas = RED; Jet = BLACK. Get a read-back of your fuel order from the FBO employee who took it. Match the fuel truck or fuel island color-coding with the color of the wing fueling decal and confirm the fuel grade again with the line service professional. Actively observe the fueling process. If something doesn’t seem right, speak up immediately. - Fuel nozzle—Check to see that the fuel nozzle is compatible with the aircraft’s fuel filler. Avgas nozzles are small and round, while jet fuel nozzles are larger and flattened like a duck’s bill at the end.

- Payment—When paying, verify that the fuel grade and quantity on the invoice match what you ordered. Many invoices and receipts are now distinctively marked to further identify the fuel grade delivered.

- Preflight—Visually check the tanks for quantity and fuel color. (It’s a good idea to pay for the fuel and attend to other last minute details before sampling. That way any contaminants will have some time to settle to the fuel tank sumps before you check them).

Drain a generous sample from each tank sump. Check for water and other contaminants, and note the fuel smell and color. 100LL has a light blue tint, while jet fuel is clear or yellowish in color. Jet fuel does not evaporate as quickly as avgas, and has a distinctive, heavier odor. If you have any doubts about the type of fuel in your tanks, do not depart.

Drain a generous sample from each tank sump. Check for water and other contaminants, and note the fuel smell and color. 100LL has a light blue tint, while jet fuel is clear or yellowish in color. Jet fuel does not evaporate as quickly as avgas, and has a distinctive, heavier odor. If you have any doubts about the type of fuel in your tanks, do not depart. -

Fuel caps—Finally, make sure the fuel caps are secure. If you lose a fuel cap in flight, fuel can siphon out of the tank at an alarming rate, and if you’re in a high-wing airplane or flying at night, you won’t be able to see it.

Fuel caps—Finally, make sure the fuel caps are secure. If you lose a fuel cap in flight, fuel can siphon out of the tank at an alarming rate, and if you’re in a high-wing airplane or flying at night, you won’t be able to see it.

Disposing of Fuel Samples

Apart from being a fire hazard, discarded fuel samples can destroy asphalt ramps over time, and evaporated fuel contributes to pollution. For those reasons (and because it’s illegal in many places) it’s not a good idea to throw fuel samples on the ground, or into the air. Some pilots shudder at the thought of pouring samples back into the tank; but if the fuel is uncontaminated, why not put it back? Some airports provide special containers for disposal of waste fuel, and pilots can purchase a GATS jar or strainers to filter contaminated samples.

Pilot Safety Announcement: Hybrid Power

Reducing energy consumption may be a laudable goal, but skimping on fuel when flight planning is not. This video clip raises awareness of proper fuel planning to prevent fuel starvation.