Afton, Wyoming—Before their transformations can begin, the worn, hard-flown Cessna 152s selected for the AOPA “You Can Fly” program must get to this mountain valley.

This final rite of passage requires crossing high elevations, contending with mountain winds and weather, and covering some very lonely stretches—a tall order for light training airplanes long past their prime.

A half dozen tough little 150 and 152 trainers arrived in Afton in the second half of 2014, and they are being remanufactured to as-new standards. Overhauled engines—along with new props, panels, interiors, hardware, and paint—will enable these proven airframes to train another generation of pilots.

But first they had to get here.

One of my first assignments this year was taking a well-worn 152—N6327M—from its former home in Show Low, Arizona, on a 600-nm winter flight to Afton. I arrived in Arizona on a cloudless afternoon, and my first impression of the airplane was decidedly mixed.

Pulling the prop through by hand, I felt almost no resistance. There was some compression in the cylinders, but it had been more than 2,000 hours since the Lycoming O-235’s last overhaul, and it felt weak. The engine oil was honey yellow, an indication the airplane had flown little, if at all, since its last oil change at the annual inspection five months earlier.

Smashed bugs were caked on the windshield. The battery needed to be recharged because it was dead from disuse. A tie-down ring on the tail was badly scraped from what I can only assume was a tail strike. And the glareshield was warped and deformed from years of exposure.

The airplane’s appearance wasn’t all bad, though. The airframe looked straight despite its having logged something like 14,000 flight hours; the tires were new and properly inflated; the Bendix/King KX-155 radio was a reliable unit; and it had that all-important cigarette-lighter adapter so I could plug in an iPad. Of course, the old Northstar Loran was worthless, but that didn’t come as a surprise.

Dean Rozeboom, an Arizona pilot and mechanic familiar with N6327M, said he was glad it was going to be restored at Aviat. “I feel like the airplane just won the lottery,” he said. “It deserves a great future, and I’m sure that it’ll have one.”

I planned a visually stunning, 230-nm hop over the Grand Canyon SFRA to St. George, Utah, on the first leg. From there, I could follow Interstate 15 to Salt Lake City and cross the Wasatch Mountains. After that, I’d be within striking distance of Afton and dash in as soon as conditions allowed. “All I need from you is six good flying hours,” I told N6327M. “Have you got three takeoffs and landings left in you?”

When I turned the key to start the engine, the prop spun absurdly fast because of the lack of internal resistance. When I plugged in my iPad, the cigarette-lighter adapter threw sparks and I could smell burning insulation. I’d have to find my way without it.

Lined up with the 7,200-foot Runway 24, I leaned for the elevation (6,415 feet) and added full throttle. Acceleration was glacial, but the engine sounded right and the prop was turning a full 2,400 rpm. After a ground roll of 1,000 feet, the airplane hadn’t quite reached its 50-knot rotation speed. At 1,500 feet, the airplane was barely ready to fly, and it climbed at about 300 feet per minute as I gingerly turned northwest.

I tried calling Albuquerque Center for flight following but couldn’t reach anyone at my altitude of 8,500 feet. N6327M flew relatively fast at 95 KIAS at 2,450 rpm, a pleasant surprise since the airplane lacked wheel fairings. I dialed in the Tuba City VOR and planned to cross Marble Canyon on the northeast side of the Grand Canyon SFRA.

Higher terrain beyond the canyon—and during the Wyoming leg of this ferry flight—would require climbing above 10,000 feet, and I wanted to find out if this airplane could reach those altitudes sooner rather than later. I nursed it all the way up to 11,000 feet and was relieved to discover it seemed willing to stay there.

The canyon overflight was exhilarating, and I snapped iPhone pictures and listened as tour pilots reported their positions in places I didn’t recognize (on 120.05 MHz).

Sunset was still an hour away when N6327M touched down at St. George, and I was pleased to discover fuel and oil consumption had been normal for the 2.5-hour trip. N6327M was showing itself to be a solid airframe, and the craftsmen at Aviat could make it great once I got it to them.

Stealing second

At dawn, I flew north in clear skies over Interstate 15 to Heber City, Utah, just 90 minutes from Afton. There, like a baseball player trying to steal second, I was ready to sprint to Afton if conditions allowed. After a night of freezing fog there, a text from photographer Cameron Lawson at the Aviat factory gave me the steal sign.

“Clear skies and calm winds at AFO,” Lawson wrote.

I followed a two-lane highway into western Wyoming’s Star Valley (the name was shortened from that of the original settlers, who called it “Starvation Valley”), and the Afton Airport came into view straight ahead—a black runway surrounded by snow. Earl Polenz, an Aviat pilot, was making calls on the Unicom frequency as he tested the newly remanufactured 152 I would be taking home to the East Coast. N6327M had provided exactly what I had hoped for: Six trouble-free flight hours, and three uneventful takeoffs and landings.

A forlorn, tightly bunched group of six faded 152s was tied down on the snowy ramp. N6327M would be joining them for a time, but these airplanes are the lucky ones. They will emerge throughout the summer as proud, like-new airplanes.

New-car smell

The flawless appearance and new-car smell of a You Can Fly 152 when it emerges from the Aviat facility can be jarring—especially for pilots who have only known these models as ratty, threadbare trainers. It’s a shock to see these diminutive, easy-to-overlook workhorses can be so, well, cherry.

“When they leave here, they’re even better than new,” said Stu Horn, owner of Aviat Aircraft, the Wyoming manufacturer that restores them. “We’ve got a lot of pride in our work, and we have very high standards for the airplanes we produce here. ”

The contrasts between the restored N152UF and the airplane I just delivered are stark: The yellow airplane’s paint is luminous. The flat metal panel is flawless, and each instrument is new or overhauled. The digital Garmin radio and transponder were just installed, and the aera 560 is so new it still has a protective plastic cover on it. The seats, carpets, and interior are factory fresh, and the Plexiglas is so transparent I’ve got to tap it to confirm it’s really there.

This rare, sunny day in the midst of a Wyoming winter won’t last long. Unless I get out of Afton in the next three hours, I’ll be grounded by snow, high winds, and low visibility for the next three days.

“Climb out of the valley on a southerly heading to at least 9,500,” Polenz says. “Then turn left for Rawlins [Wyoming, the first planned fuel stop]. You should pick up a nice tailwind.”

With an outside air temperature of 25 degrees F, N152UF energetically climbs above 10,000 feet, and engine temperatures and pressures are solidly in the green. I’m running the engine hard for break-in, so this first leg will be relatively short at 2.0 hours to calibrate fuel and oil consumption.

The cabin heater and wool socks keep my feet warm, but I’ve neglected to tape over the cabin air intakes, so cold air swirls at the wing roots. In less than an hour I’ve crossed the snowy peaks and follow a barren, windswept plateau (elevation 8,300 feet msl) that stretches for miles.

The surface wind at Rawlins is gusting to 30 knots, but in a direction that’s mercifully aligned with the runway. Tumbleweeds and trash blow across the ramp as I shut down in a windbreak provided by a metal hangar. N152UF takes just 14 gallons of fuel, slightly less than I’d guessed, and I head east again to escape the coming weather.

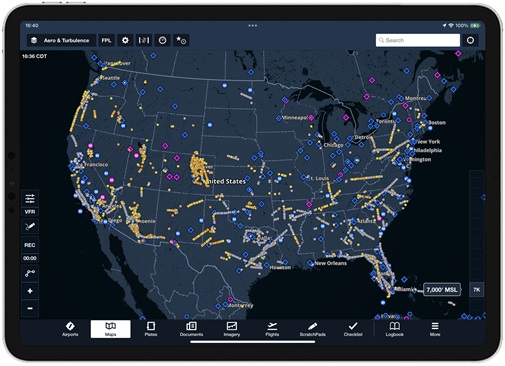

I consider landing at Cheyenne, but the Garmin GDL39 ADS-B receiver on the glareshield says the forecast anticipates 50-knot wind gusts. Laramie is closer, and the winds are a mere 25 knots. I land as the sun is beginning to set, and Cowboy Aviation has both hangar space and a courtesy car.

The next morning, I’m in the airplane at daybreak, and conditions are dreamlike for an eastbound flight—clear skies, smooth air, and a booming west wind. At Cheyenne, the 152’s groundspeed swells to 152 wind-aided knots.

People’s reactions to the airplane vary. Some instantly recognize it as a You Can Fly 152, but others have never heard of the AOPA program. Two older gentlemen approach the airplane. One inspects it closely while the other stands 30 feet away, hands in pockets. I invite both to take a look inside.

“I’ve seen plenty of 152s,” the incurious one says dismissively. “I don’t need to see another.”

His friend’s answer: “You’ve never seen a 152 like this one. I sure haven’t.”

Another leg to Fort Wayne, Indiana, gets the airplane into a heated hangar for the night and shelters it from the freezing fog that arrives in the wee hours.

The next day I plan to make a fuel stop in Ohio, but the booming west wind makes that unnecessary. I land in Frederick after a three-hour, 400-nm hop. It requires climbing high again, 9,500 feet for most of the trip, but a 50-knot tailwind over West Virginia is too good to pass up. On landing the tachometer reads 16.5 hours.

AOPA Senior Aviation Technical Specialist Rodney Martz greets N152UF on the ramp. He located and purchased the airplane, and helped coordinate its transformation. Now, Martz finally sees the result of his efforts.

“I’m not supposed to have favorites, but I really like the way this airplane turned out,” he said. “I’m looking hard, but I can’t see any flaws in it.”

Email [email protected]

Photography by Cameron Lawson

Sweepstakes Sponsors:

• Aircraft Spruce

• Airtex Interiors

• AMI/AWI

• Garmin

• LP Aero Plastics

• Omaha Airplane Supply

• Plane Power

• PS Engineering

• Sky-Tec

• Stene Aviation

• Univair

• Vantage Plane Plastics

A few good airplanes

Most buyers look for low-time airplanes with freshly overhauled engines, spotless interiors, and lustrous paint. Not AOPA.

The Cessna 150s and 152s selected for the Reimagined program generally came with high-time engines, dated interiors, and faded paint.

“The airframes are going to be remanufactured, the engines are going to be overhauled, and they’re all going to be repainted, so there was no reason to seek out newer aircraft,” said AOPA Senior Aviation Technical Specialist Rodney Martz, who found and researched the airplanes the association eventually purchased. “We wanted airplanes that had been in continuous service with good paperwork documentation, and no corrosion. We turned down several airplanes because of corrosion concerns.”

Josh Schmidt, a Maryland-based commercial pilot and ground instructor seeking to build flight time, delivered four 152s to Wyoming for restoration. Along the way, he overcame vacuum pump and alternator failures, low ceilings, and headwinds that reduced his forward progress to as little as 30 knots.

“The flights were exciting, boring, satisfying, and scary—all rolled into one,” said Schmidt, 31, who logged a total of 100 hours on four westbound trips. “In the mountains, you’ve got to know where you’re going to encounter lifting air and sinking air. It’s almost like flying a glider.”

Highlights included a full-moon trip across the Midwest with moonlight reflections on the snow-covered ground bright enough to illuminate the area for miles. “I got to go places I hadn’t been and build time toward the 1,500 hours I’ll need for an ATP,” Schmidt said. “It’s been an adventure.”

Martz said he thought about the demanding flights to Afton during each prepurchase inspection. “I knew every airplane had to be in good enough shape to fly to Afton, probably in the dead of winter, and that’s asking a lot,” Martz said. “It’s not an easy place to get to.” —DMH