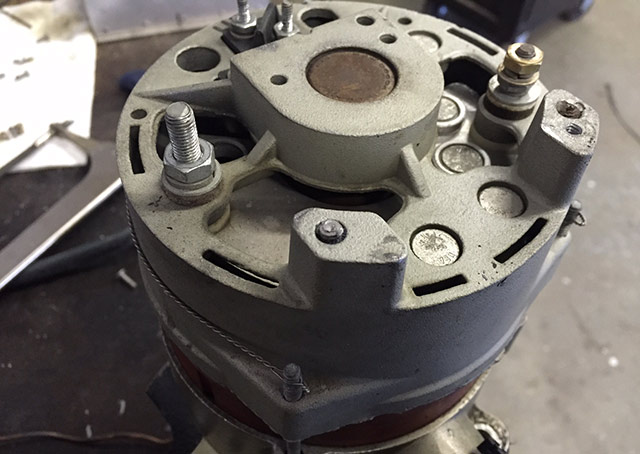

If there’s one thing that doesn’t go well with aircraft maintenance it’s being in a rush. I was recently reminded of this when I fell off the “proper aircraft maintenance wagon.” I was reattaching a noise filter to the aircraft’s alternator. Time was of the essence, so I put the small support bracket in place on the alternator and quickly tightened the attaching screw. Too quickly it seems, because it took only a few turns for the head of the screw to snap right off, leaving the remainder of the screw in the alternator.

To be fair, most general aviation aircraft use automotive alternators with “less than mil-spec” quality hardware built into them. The offending screw was even cheaper quality than you would find at your local hardware store, so it didn’t take much to break it. I also like to think that I subconsciously create these little “teaching moments” just so that I can write about them in the hope that I’ll save someone out there from a similar fate. But I digress…

At some point in time, anyone involved in aircraft maintenance is bound to encounter a broken screw or bolt. So let’s take a look at what it takes to remedy the situation.

Step 1: Assess the situation

In the very rare case that a large enough portion of the screw remains accessible, you may be able to get a grip on it and twist it out. Carefully check to see if a pair of locking pliers can get a grasp on it. If they can, don’t just dive in. Consider pre-soaking the screw in mouse milk and then clean it off before beginning the removal process. Add some valve grinding compound to the jaws of the pliers, make sure they are squarely on the screw, lock them tight, and gently twist. If this process works, proceed directly to the nearest location to buy a lottery ticket. It’s your lucky day and you should make the most of it.

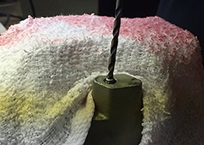

Step 2: Use a quality “easy out” screw extractor

For those of us who didn’t win the lottery, the offending screw must be removed the old-fashioned way. Be sure to use a high-quality screw extractor, possibly borrowing one from your local shop. File the top of the screw flat if necessary, so that you can get a drill started perfectly centered in the screw. Drill very slowly and carefully, checking regularly to ensure that you are drilling straight and true. You don’t want to damage the threads.

Next, insert the screw extractor and make sure that it fits all the way into the hole you drilled. If you drill your pilot hole too shallow, the extractor will bottom out before it gets the grip it needs. Turn the extractor by hand counter clockwise and the screw should rotate out.

|

|

|

Step 3: Use a tap, if necessary, to finish the job

If the resulting hole has damaged threads, you will need to use a tap to see if it can be salvaged. If it cannot, you may have to drill the hole one size larger and re-tap it for the next-diameter-larger screw or bolt.

The best advice I can give is to take your time. Be sure to protect the surrounding material from damage or debris while drilling or tapping, and go slowly. In many cases, being in a rush caused the problem to begin with, so don’t compound it with rushing the solution. And, as always, use the proper torque when working with any fastener. That way you can avoid my experience altogether and just keep these tips filed away for some hypothetical future need. Happy flying!

Interested in aircraft maintenance? View the archives of Jeff Simon’s Aircraft Maintenance series.

Jeff Simon is an A&P mechanic, pilot, and aircraft owner. He has spent the last 14 years promoting owner-assisted aircraft maintenance as a columnist for several major aviation publications and through his how-to DVD series: The Educated Owner. Jeff is also the creator of SocialFlight, the free mobile app and website that maps over 20,000 aviation events, airport restaurants, and educational aviation videos, including many how-to videos for the subjects of these articles. Free apps are available for iPhone, iPad and Android, and on the Web at www.SocialFlight.com.

Jeff Simon is an A&P mechanic, pilot, and aircraft owner. He has spent the last 14 years promoting owner-assisted aircraft maintenance as a columnist for several major aviation publications and through his how-to DVD series: The Educated Owner. Jeff is also the creator of SocialFlight, the free mobile app and website that maps over 20,000 aviation events, airport restaurants, and educational aviation videos, including many how-to videos for the subjects of these articles. Free apps are available for iPhone, iPad and Android, and on the Web at www.SocialFlight.com.