Synthetic vision helps save the day

I was flying from Ohio to Iowa on the day after Christmas with my wife, Stephanie, and our dog Piper. Our airplane is an immaculately maintained 1970 Bonanza A36. It has full ADS-B datalink, Stormscope, WAAS GPS, a certified standby electronic flight instrument system, and engine analyzer.

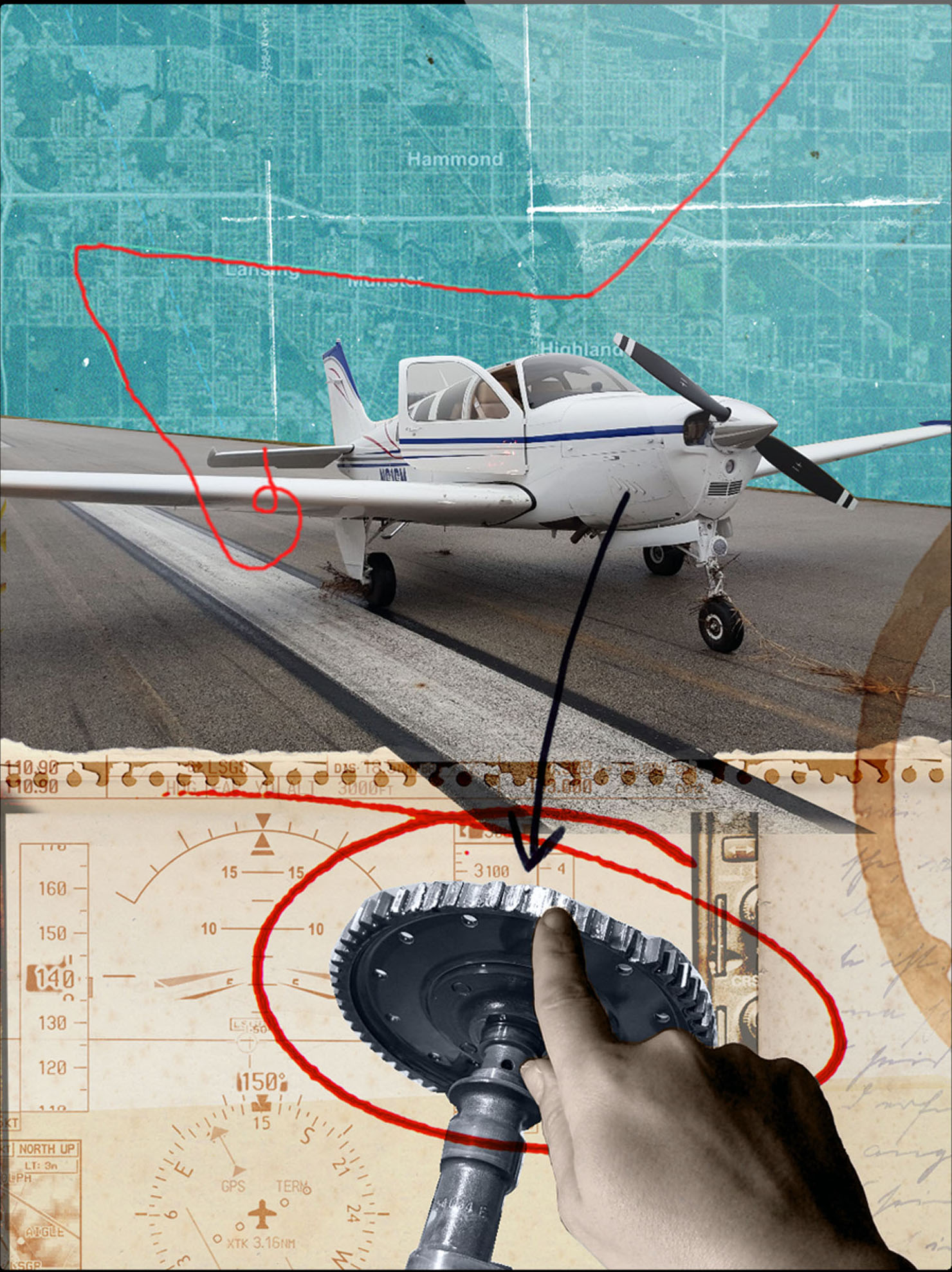

We could not make it through the weather direct to Cedar Rapids and landed at Gary/Chicago International Airport (GYY) in Gary, Indiana, to take on fuel. After departing Gary, pressures and temperatures were normal as indicated on an Electronics International MVP-50P engine analyzer. Shortly after rotation, but before entering the overcast layer, I heard a faint “clacking” sound. The engine was still developing full power and all indications were normal. I assumed it was an anti-chafe strip that had come unglued and was smacking against the fuselage. This sound continued throughout the climb and turn to heading.

All engine indications remained normal throughout the initial climb, and I reduced power to 25 inches and 2,500 rpm. We climbed through a 1,000-foot layer with bases of around 600 to 700 feet agl. As the climb continued, I leaned the engine as normal.

Just before reaching a cruise altitude of 6,000 feet, there was a momentary decrease in rpm, and about a second later, a complete loss of engine power. I tried sweeping through the throttle control, going full rich, sweeping the mixture control closer to cutoff, then back to where it was. None of this had any effect on power.

Sometime while doing this, I pitched for 110 knots, best glide. Shortly thereafter, I noticed that the fuel pressure indicated on the engine analyzer was at zero.

Assuming the issue to be an engine-driven fuel pump failure, I turned on the electric fuel pump. Indicated fuel pressure jumped on the MVP display, but the engine didn’t start developing power. I smelled a very strong fuel odor, shut down the electric pump, and turned off the tank and set the mixture to cutoff. I darn sure was not going to go down in flames. Nothing seemed like it was going to bring the engine back, anyway.

I had managed to call up Chicago Approach and declare a mayday. I said I was turning to the nearest airport, which appeared to be Lansing Municipal Airport (IGQ). Garmin Pilot’s Map page on my yoke-mounted iPad showed Lansing about 90 degrees left of course. I proceeded at best glide, prop pulled to low rpm.

Chicago Approach offered the runway information. I said I was going to land on the first one I could see. Abeam the airport, I switched the iPad to the Synthetic Vision page and could see the runway layout and the (thankfully flat) terrain. Then we entered the clouds.

I circled the perimeter of the airport, as I saw it in the synthetic vision system display, in a left standard-rate turn, at approximately 110 knots. I kept scanning between the SVS and out my left window, waiting to pop out of the layer.

At what must have been the same 600 or 700 feet agl I departed in, I saw a runway out the window, and it must have been Runway 18/36. The 18 approach end would have been an impossible turn in the altitude remaining. I set the gear down but kept flaps up. I looked farther out and saw a clearing and Runway 27 out in front, but there was too little altitude remaining to reach it.

Just prior to the clearing at midfield of Runway 27/9 was a deep drainage ditch perpendicular to my path. I remember telling my wife to brace for impact. Somehow, by the grace of God, the airplane got in ground effect and managed to stay off long enough to clear that ditch. We ended up on soft, but flat, ground. I kept the nose up in the rollout as best I could. Apparently when we reached the Runway 27 centerline I must have kicked the rudder to the left and lined the airplane up on the centerline for the rest of the rollout. I think at that point I looked over at my wife and said, “Evacuate the airplane.” She opened the door and unbuckled, while I grabbed the dog and carried her out.

Four minutes and 30 seconds from engine failure to touchdown.

The engine was a Continental IO-520-BA with 1,250 hours since factory remanufacture. With the camshaft not turning, the fuel and oil pumps were inoperative. The magnetos were not indicating correct rpm, and the cam-driven prop governor was unable to decrease propeller rpm. The fuel smell was fuel from the electric pump flowing from the injectors, down the induction tubes, and out the induction drain. The engine failure was catastrophic and unrecoverable. Engine teardown revealed that a cam gear failed catastrophically by cleanly shedding three teeth.

My takeaways for this event:

Reading crash reports can save your life. I recall a similar A36 engine failure in IMC where the pilot asked ATC for assistance, didn’t get anywhere near an airport, struck a house, and died. That LiveATC.net recording was etched in my memory from months ago. There was discussion about whether to accept ATC vectors, try to fly an approach, or circle over an airport until you break out. If you turned straight for the airport and had the altitude, then that last one works. At least you’ll end up over something flat and sparsely populated. Don’t waste altitude.

Avionics with synthetic vision can be worth every penny. I have a FlightStream 210 driving an iPad mini with Garmin Pilot. Having the map display up enabled me to assess the situation and turn immediately to arrive abeam an airport. The mental effort to do this with a detailed moving-map display is minimal. The synthetic vision system provided reference to fly by while keeping me terrain-aware. I was not originally a proponent of SVS, operating under the belief that as an instrument pilot, following procedure would keep me out of situations where I would need it. I’m glad I have it.

I was able to pull this off because the ceiling was more than 600 feet. The outcome could have been very different if I hadn’t had the time to find the field. Legal isn’t necessarily safe, and most engine failures (not related to fuel mismanagement) occur during departure.

Finally, I’m thankful I practice spiral descents and 180-degree precision power-off landings, and I yell at my students to “just fly the damn airplane.” There wasn’t time for much else. AOPA

Matt Anker is a commercial single- and multiengine pilot and single-engine CFI. He is a self-employed contract flight test engineer for Pratt & Whitney.

Digital Extra: Hear this and other original “Never Again” stories as podcasts every month on iTunes and download audio files free.