Struggling to control his stricken Baron and ditch it in the Gulf of Mexico as thick smoke obscured the instrument panel, and his view outside, Texas pilot Theodore Wright in 2012 joined a (thankfully) small but growing group of pilots who have faced what is certainly among the worst of worst-case scenarios, and survived.

Cockpit smoke has been a problem since cockpits were enclosed. A tested and certified solution exists, one that displaces rather than dilutes smoke. A demonstration model was installed in January at Banyan Air Service, a sprawling FBO at Ft. Lauderdale Executive Airport.

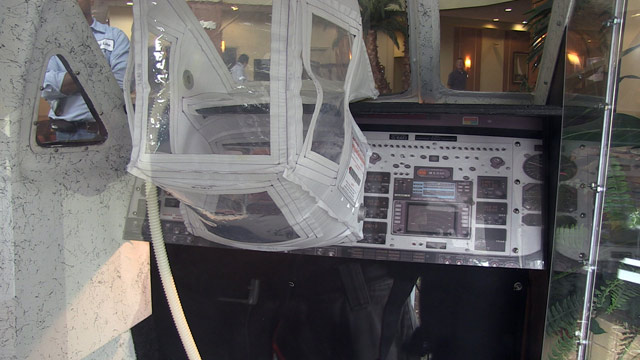

It is simplicity itself: The Emergency Vision Assurance System is essentially a balloon in a box, with clear plastic windows that press against the windshield and face the pilot. The box contains an air filter and inflation pump. Deployed on the glare shield, the balloon inflates in less than a minute, displaces smoke, and offers a reasonably clear view of both the outside world, and instruments. A recent demonstration in the Banyan Air Service lobby arranged by the FBO staff proved this much: Even in a mock cockpit full of theatrical smoke thick enough to obscure a hand held an inch or so in front of a facemask, pressing that same protective mask against the EVAS window revealed the world outside, in detail.

VisionSafe Corp., maker of the EVAS invented by Bertil Werjefelt more than 20 years ago, hopes the FBO demonstrator will help sell general aviation pilots and owners on the value of a system that costs $17,000 per pilot position, and has been slow to catch on since the current model was introduced more than a decade ago.

VisionSafe Vice President Jonathan Parker said about 2,000 units are currently installed. Pressed by pilots, JetBlue has purchased units for its larger aircraft, along with FedEx, but most of the sales have gone to corporate flight departments.

“They look at things a little bit differently, and the budgets are controlled differently,” Parker said. “The people who control the budgets are the passengers on board.”

‘No magical smoke-off switch’

Pilots, particularly airline pilot unions, have been urging federal officials to mandate some kind of smoke displacement system for more than a decade, and EVAS remains alone in the market in the ability to displace rather than dilute the smoke. The NTSB urged implementation of a smoke displacement mandate in 2002, though the FAA opted to leave it to the market to decide (while installing EVAS units in FAA-operated jets starting in 2003). The 2012 FAA reauthorization legislation includes language that triggered an investigation of current cockpit smoke regulations—and their efficacy—by the Government Accountability Office, with a report expected in June. The GAO is focusing primarily on regulations that pertain to “commercial” operators, according to a spokesman, an arena where EVAS is slowly starting to take hold. The FAA currently requires Part 121 operators to manage cockpit smoke by venting or diluting it with clean air, within limits: Such systems require that smoke be cleared sufficiently to allow the pilot to see within three minutes after the smoke is stopped at the source.

“We know there’s no magical smoke-off switch,” Parker said, interviewed by telephone along with Werjefelt, who called the current regulations “totally unacceptable.”

‘Pilot reported smoke’

Parker said there have been just three documented cases of EVAS deployment to date, at least one of which certainly saved many lives, though a few other units have been returned for factory service (as required after deployment) with soot inside, but no explanation. Smoke in cockpits—particularly smoke thick enough to obscure a pilot’s vision—is comparatively rare. It also appears to be rare that such incidents are documented: Only four accidents in the NTSB database contain the phrase “pilot reported smoke,” all of them fatal, and most recently a Mooney M20M that crashed in 2001 in Indiana, with two lives lost. The FAA Accident and Incident Data System lists 39 reports with that same phrase since 1978, all but five involving GA aircraft.

Such events are much more common in media reports, including seven incidents in February alone that prompted emergency landings: A Lancair 360 crash that injured the pilot and passenger, a United Airlines flight from London to Los Angeles forced to make an emergency landing in Ireland, an American Eagle flight forced to return to Miami by cockpit smoke, and a British Airways emergency landing reported to be among four related to smoke and fumes that the airline’s flight crews had to deal with in a three-week period.

‘Could have been the difference’

Wright, in a recent email conversation, said he was not sure EVAS would have made a difference in his particular case—he was able to vent enough smoke from the Baron to see the water just well enough to ditch.

“However, if I was over land, this device could have been the difference between life and death,” Wright wrote. “I do not know that I personally would spend ($17,000) to retrofit into an old aircraft, but I certainly see how the price would not be much of an issue on a new aircraft … I would love to see them at least offered as an option on new production aircraft, even light singles and twins.”

Parker said VisionSafe can custom-manufacture an EVAS to fit any aircraft, though the cost would remain the same as the production model.

“For a [Cessna] 310, we actually already have equipment designed,” Parker said, noting it was a special order by a customer also operating other aircraft, “and we do for some other GA airplanes. It would have to be carried as loose equipment.”

Parker said the cost is driven in large part by the high cost of certification incurred (the company has secured supplemental type certificates for various turbine aircraft under Part 25, along with various air transport aircraft). The cost of custom-manufacture is also a factor, with mandates and requirements that result in nearly as many people monitoring production as actually producing, Parker said.

“We would have to make the investment to develop the equipment,” Parker said. “It’s unfortunate that we can’t bring the price down lower.”

Werjefelt said that when he developed the first prototype about a quarter-century ago, he envisioned life-saving potential that would extend to all corners of aviation. If a mandate results from the current GAO investigation, the price is likely to drop.

“If we get up to some reasonable volume, the price would come down,” Werjefelt said.

As for his hopes that his unique and simple invention would save lives on a grand scale, it “didn’t turn out that way. It’s very frustrating.”