Aircraft Maintenance: Dynamic propeller balancing

Part Four: Propeller maintenance

With all that mass spinning at the pointy end of the airplane, even small imbalances can cause big vibrations—and vibration is the enemy of just about every system on the aircraft, including you.

Engine mounts, magnetos, instruments, avionics, control systems, and just about every part of the aircraft can be affected by excessive vibration. If you are finding loose rivets and cracking in the aircraft cowling or spinner, it pays to see what the vibration is at the propeller.

Dynamic balancing is accomplished using specialized equipment that can accurately measure the vibration and, most importantly, pinpoint exactly where the imbalance exists. One of the most popular systems on the market, and the one I have the most experience working with, is the DynaVibe GX3 system from RPX Technologies. The DynaVibe system consists of a handheld analyzer with accelerometer sensors that attach to the engine case to measure the vibrational movement of the engine and prop in inches per second (IPS). It also includes an optional tachometer, making it possible to measure the RPM of the engine during testing, as well as the exact position of the prop so that the amount of movement can be correlated directly to the position of the prop to develop a solution to remedy the imbalance.

The process begins by mounting the accelerometer to the engine (a second accelerometer can be added to the back of the engine for an even more detailed analysis of engine movement) as well as mounting the optical tach in a position where it can “see” each pass of the propeller. A strip of reflective tape is applied to the face of the prop blade designated as the No. 1 blade for the process. Cables are run into the cockpit and hooked up to the DynaVibe analyzer. The user interface of the system makes it easy to enter the details of the aircraft, including the owner and aircraft tail number. This information is used later in a printed report from the system.

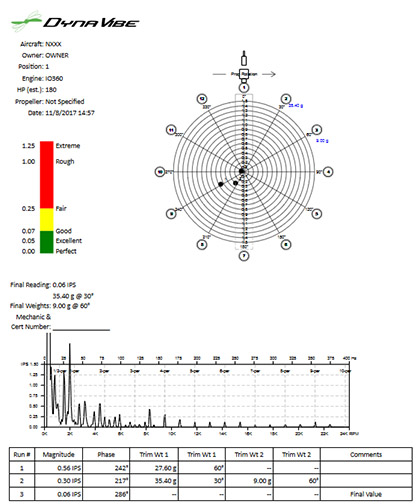

At this point, the aircraft is started, warmed up, and brought up to full power (or the cruise power settings that we want to target for the balance process). Once everything is stable, the DynaVibe does an analysis in about seven seconds, the engine is shut down, and the balance process begins. The system outputs the vibration magnitude (in IPS) and the angle at which the imbalance exists. It also creates a “solution” for the mechanic to implement to offset the imbalance and reduce the vibration. The solution involves adding weight either on the prop spinner or on the flywheel (on Lycoming engines) opposite the location of the existing heavy spot. Since flywheels and spinners have pre-existing locations for mounting screws or bolts, the system automatically suggests a “Split Solution” that tells the mechanic how to allocate the weight among the existing locations without drilling new holes.

Weight is typically added in the form of screws, nuts, and washers (or bolts if on the flywheel). Once the weight has been added and entered into the DynaVibe, the process is repeated with subsequent refinements until the results are satisfactory. The goal is to get within 0.07 IPS. When the process is complete, don’t forget to remove the reflective tape to avoid the risk of corrosion.

During a recent propeller balancing exercise, we measured the initial vibration at 0.56 IPS; a significant vibration that the owner had been flying with for some time. After the balancing process, including three passes at refining our solution, we had the vibration down to 0.06 IPS. The difference was so significant that the owner took the time to email me after he got home, noting the dramatic difference he felt on his flight home. I suspect every other part of his aircraft had a more relaxing flight home as well.

Dynamic propeller balancing is the last step in making sure that your propeller is operating at its best. However, it’s important to keep in mind that any changes to the system will require rebalancing. If the prop is removed and reinstalled, if repairs are made, or if something significant is changed on the engine, it is advisable to re-check the balance. It’s amazing how much more comfortable flying can be with less vibration. With a little effort, both you and your airplane will arrive with a little less wear and tear. Happy flying!