Power up, temps down: King Air 250

Better induction airflow and winglets make the newest King Air at home in the mid-thirties

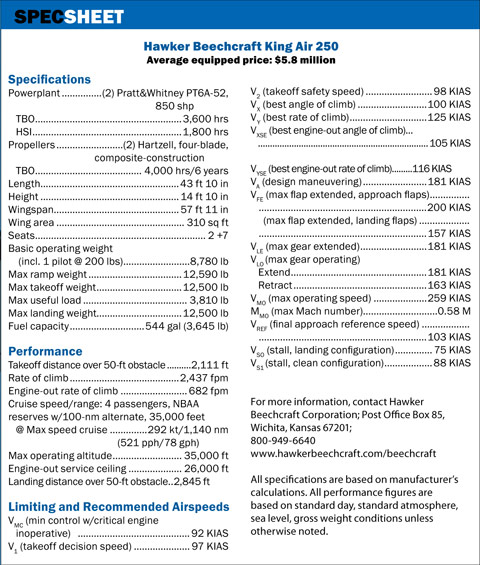

In late June, Hawker Beechcraft Corporation (HBC) certified its new King Air 250, a more refined variant of its predecessor, the King Air B200GT. Like all King Airs, the 250 has the classy, comfortable cabin that has made the line the go-to twin turboprop for more than 7,000 customers. But the 250 brings still more incremental performance improvements to the B200 line, thanks to some clever airframe and powerplant tweaks.

Ram air recovery

One big improvement is a new ice vane design in the 250’s twin 850-shaft horsepower Pratt & Whitney PT6A-52 engines. These are the same engines used in the B200GT, but, according to Hawker Beechcraft, the new ice vanes keep the 250’s interturbine temperatures (ITTs) cooler, yield an eight-percent increase in available horsepower, and make the airplane eight to 11-percent more fuel efficient than the “old” B200GT.

August 2011

Turbine Pilot Contents

- Turbine Intro: Mods to An End

- Power Up, Temps Down: So long, B200GT. Say hello to the new King Air 250

- Mentoring Matters: Where’s that fix?

To understand how this works, cast your mind back to ground school and recall that turboprop engines need a way to prevent ice and dirt particles from entering the engine, lest they damage the compressor blades and other fast-moving internal components. Ice vanes—some manufacturers call them inertial separators—perform this function by redirecting this contaminated air away from the engine and send it overboard through a dedicated channel. The pilot can open the ice vanes/inertial separators during ground operations if dirt or gravel is a factor, or in the air when flying in icing conditions. This is great, but there are prices to be paid. Diverting air from the engine deprives it of torque and power, and also causes ITTs to run hotter. And because ITTs have limits, power has to be adjusted down in order to keep from hitting ITT redlines.

The effect is cascading. Less available power means slower times to climb, which means increased fuel burns on the way up; slower cruise speeds and higher fuel burns at altitude; and flirting with ITT redlines when cruising deep into the flight levels. To minimize these compromises, HBC went with Raisbeck Engineering’s King Air Ram Air Recovery system. This uses an ice vane with an airfoil shape. The airfoil helps preserve some of the diverted airflow for the engine, which HBC says gives the 250 ITTs that are 20 degrees Celsius cooler at any given torque setting, plus the other benefits mentioned earlier. It’s the airfoil shape that’s key. Most ice vanes/inertial separators amount to flat trap doors that create lots of inefficient, turbulent airflow downstream. The Ram Air Recovery system keeps the flow streamlined and that keeps power up and ITTs down, whether or not the vanes are deployed.

Winglets to the rescue

The 250 also sports a pair of Boundary Layer Research (BLR) carbon-fiber winglets. These give the 250 a 57-foot, three-inch wingspan, which is three feet, five inches longer than that of the B200GT. This increase in effective wing area is important on its own merits when it comes to lowering the 250’s clean-configuration stall speed (which is 88 KIAS, down from the B200GT’s 99 KIAS). But the winglets also cut induced drag—the drag created by wingtip vortices and lift at slower speeds and high angles of attack—which translates into the 250’s improved sea-level, max-gross takeoff distances (2,111 feet versus the B200GT’s 2,579 feet). Under hot-and-high (5,000-foot field elevation, 25 degrees C) conditions the 250 uses about 1,000 fewer feet of runway—and that’s with an 800-pound payload. So the net effect of merging the Ram Air Recovery system with the winglets is to ratchet up the 250’s performance, both down low and up high. For example, the 250’s max gross takeoff weight may be the same as the B200GT’s—12,500 pounds—but the 250 gets to FL350 four minutes quicker and has a single-engine service ceiling of 26,000 feet, nearly 2,000 feet higher than its predecessor. Moreover, the 250 cruises some five knots faster using about 60 pph (about nine gph) less fuel.

“To keep it simple, I think of the 250 as a 300-300-300 airplane,” said HBC’s senior demonstration pilot, Luke Scott. “Although it’s perfectly happy cruising at FL350 doing 290 knots and burning 260 pph per engine.” Scott was also quick to emphasize that the 250’s M MO was raised to Mach 0.58.

Flight notes

After waiting for a rather large meso-cylone to pass by, I slid into the 250’s front office with Scott for a brief demo flight. The King Air cockpit is a comfy place, and even though all new King Airs now have the Rockwell Collins three-screen Pro Line 21 avionics suite, the rest of the panel, center pedestal, sidewall, and overhead panels retain the traditional gauges, switches, and knobs that will be so familiar to generations of King Air pilots. Ditto the engine start and preflight systems checks.

N406KA was at maximum takeoff weight for my flight out of Beech Field (BEC), which is adjacent to the Hawker Beechcraft factory in Wichita. V 1 and V R are 97 KIAS at that weight, and V 2 was 98 KIAS. The numbers were plugged into the Pro Line primary flight display (PFD) using the “refs” line select key to the PFD’s left. Then it was line up and wait, cleared for takeoff, and power up. Initial climb rates at 120 KIAS were in the 2,200-fpm ballpark. The cruise climb speed schedule had us using 160 KIAS to 10,000 feet, followed by 140 KIAS from 10,000 to 20,000 feet, 130 KIAS from 20,000 to 25,000 feet, and then 120 KIAS from 25,000 to 35,000 feet. After 31 minutes we were leveling at FL350. HBC advertises 24 minutes, but that’s for standard conditions.

N406KA was at maximum takeoff weight for my flight out of Beech Field (BEC), which is adjacent to the Hawker Beechcraft factory in Wichita. V 1 and V R are 97 KIAS at that weight, and V 2 was 98 KIAS. The numbers were plugged into the Pro Line primary flight display (PFD) using the “refs” line select key to the PFD’s left. Then it was line up and wait, cleared for takeoff, and power up. Initial climb rates at 120 KIAS were in the 2,200-fpm ballpark. The cruise climb speed schedule had us using 160 KIAS to 10,000 feet, followed by 140 KIAS from 10,000 to 20,000 feet, 130 KIAS from 20,000 to 25,000 feet, and then 120 KIAS from 25,000 to 35,000 feet. After 31 minutes we were leveling at FL350. HBC advertises 24 minutes, but that’s for standard conditions.

On that June day temperatures varied between ISA +10 and ISA +18 degrees C, and even slightly above-standard temperatures can be murder on climb rates. Comparatively speaking, our density-altitude penalty, was not great at all. Then we set up the engines for a high-speed cruise at FL350. Bear in mind that King Airs traditionally haven’t exactly shined when flying this high. Like most turboprops, they are fastest in the denser air of the mid- to high twenties. So it was a pleasant surprise to see the 250 true out at 302 knots—especially at our weight, and especially under ISA +10 conditions.

We had beaten book speeds by about 10 knots. The torque settings for that cruise gave us ITTs hovering around 800 degrees C, some 20 degree below the 820-degree ITT redline. Fuel burn was 250 pph (about 37 gph) per side—another advantage of cruising up high. The propellers were set at 1,800 rpm, which is normal for maximum cruise power and which, with the cabin’s tuned vibration dampeners and bagged insulation, kept noise levels so low that conversations could be held with ease.

That 300-knot cruise reminded me of a comment a veteran King Air pilot once made on a flight years ago. We were at FL300 in a B200, forced that high in order to dodge cumulonimbus tops. “Bet you never thought you’d be cruising at 300 in a King Air,” he commented. Not then, maybe, but the odds seem better now.

That 300-knot cruise reminded me of a comment a veteran King Air pilot once made on a flight years ago. We were at FL300 in a B200, forced that high in order to dodge cumulonimbus tops. “Bet you never thought you’d be cruising at 300 in a King Air,” he commented. Not then, maybe, but the odds seem better now.

The descent brought out another change made with the 250. Its M MO (maximum Mach number) has been raised to Mach 0.58; before, it was Mach 0.52. This gives you roughly 30 more knots to work with, which is helpful in making up for any speed sacrificed in the climb. Why the hike in M MO? Scott said it was easily certified because the airplane shares so many of the same basic structures as the King Air 350, which already has a Mach 0.58 M MO.

Landings

With the thunderstorm complex out of the picture, it was time to wind up the flight with some landings at Beech Field. With the extra wing area I was told to expect more of a float in ground effect than earlier King Airs.

But alas, the winds had kicked up to bless me with 20-plus knots of gusty direct crosswinds, and my touchdowns were more like arrivals than landings. My bad. In any event, I’d like to think they were anomalies, because all King Airs are easy to land.

With the King Air 250, HBC offers more performance than the B200GT without sacrificing the GT’s useful load or maximum range. It’s a natural evolution of the 200 series, and one that should garner a decent market share.

After all, if you’re looking for a new twin turboprop, then your choices narrow to just a few popular makes.

Email the author at [email protected]. Photography by Mike Fizer.