Photography by Mike Fizer

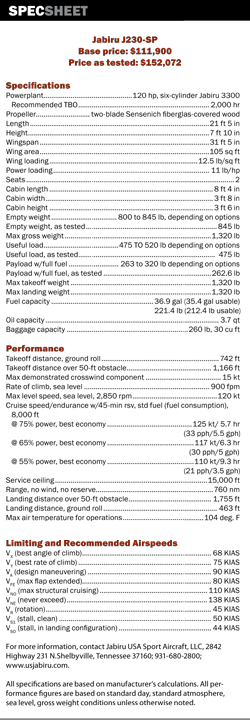

With the pattern at Avon Park, Florida, clear of traffic, I taxied the Jabiru J230-SP light sport aircraft (LSA) onto the runway behind an older Cessna 172 carrying AOPA Senior Photographer Mike Fizer. Despite letting the Cessna start its takeoff roll and reach rotation speed prior to releasing the hand brake, the 120-horsepower Jabiru quickly caught the 160-horsepower Cessna on the climbout and could barely stay behind it. The Jabiru was a hawk that had just seen lunch—the 172.

At that point, Nick Otterback of Jabiru USA Sport Aircraft in Shelbyville, Tennessee, and I decided to depart the formation and return only after the older model Cessna had a chance to catch its breath. Prior to the flight, the Cessna pilot and I had agreed to keep climb and cruise speeds low—a concession the Jabiru didn’t need.

Powering up a minute or two later to rejoin the 172, I heard the unique sound of the six-cylinder Jabiru engine—a throaty low pitch like a high-performance motorcycle. Katie Bosman, a demonstration pilot and technical writer for Jabiru USA Sport Aircraft, said she can instantly recognize the Jabiru engine sound from the ground.

“The Jabiru 3300 [engine] has a deep, throaty growl that sounds almost Cirrus-like when it flies overhead. There is nothing else quite like it,” she said.

First impressions

Fit and finish has improved dramatically over the Jabiru first placed on the market in 2006, and the buying public has responded. The website bydanjohnson.com ranks the Jabiru as the seventh best-selling LSA.

Looking at the Jabiru fuselage from a distance, you’d swear it’s a four-place airplane, because that’s how it was originally designed. As an Experimental-category airplane, whether in Australia or the United States, the airplane has a gross weight of 1,600 pounds and can have four seats. In that configuration, the aircraft becomes a J430.

An LSA, whether in the United States or Australia, must meet a gross weight limit of 1,320 pounds and have only two seats. It carries 35.4 usable gallons of fuel. As an LSA the useful load hovers around 500 pounds depending on options. As an Experimental category 1,600-pound homebuilt aircraft (there are 30 of those flying in the United States), the useful load approaches 800 pounds, meaning three average adults can ride in it. There’s even a separate door for the backseat passengers. To meet ASTM LSA standards for the United States, the two rear seats were removed, creating a huge cargo space with its own door.

An LSA, whether in the United States or Australia, must meet a gross weight limit of 1,320 pounds and have only two seats. It carries 35.4 usable gallons of fuel. As an LSA the useful load hovers around 500 pounds depending on options. As an Experimental category 1,600-pound homebuilt aircraft (there are 30 of those flying in the United States), the useful load approaches 800 pounds, meaning three average adults can ride in it. There’s even a separate door for the backseat passengers. To meet ASTM LSA standards for the United States, the two rear seats were removed, creating a huge cargo space with its own door.

Getting into any of the more than 100 LSA models on the market is like folding clowns into a tiny circus car. You must make a decision as to whether entering with your caboose first, or your engine (head), is best for you. I chose the engine method, and found that my candy-enhanced caboose was a tight fit once in the seat. The cabin is 44 inches wide, but 43.5 inches down at the hips. A center console takes up 2.5 inches of that available hip space. Company officials say that is the chief complaint from, well, larger individuals.

Once halfway in, typical LSA models require you to launch the right leg over the control stick before bringing the left leg in. That’s not true in the Jabiru, which has a single stick with two horns in the center console. The pilot in command uses the left horn, while the right horn is available to an instructor or copilot.

Aussies have a reputation of being tough and laid back. The Jabiru LSA, with its Jabiru-manufactured engine, reflects that culture: rugged, but few frills. Jabiru USA Sport Aircraft buys aircraft kits from Australia—an airplane in a box—and assembles them in six weeks in Tennessee. The company therefore deserves the credit for improvements in fit and finish of the United States model over the years.

Aussies have a reputation of being tough and laid back. The Jabiru LSA, with its Jabiru-manufactured engine, reflects that culture: rugged, but few frills. Jabiru USA Sport Aircraft buys aircraft kits from Australia—an airplane in a box—and assembles them in six weeks in Tennessee. The company therefore deserves the credit for improvements in fit and finish of the United States model over the years.

Pete Krotje (pronounced crotti), chief manager and majority owner of Jabiru USA offering Jabiru kits, engines, and finished light sport Jabirus, said ruggedness is what sets his aircraft apart from the rest—the design and strength of the airframe. “A lot of these [LSA] airplanes, especially the ones coming from Europe, were designed as an ultralight or microlight at a 990-pound gross weight, because that’s the limit they had to stay under to stay in that class,” Krotje said. “When they first came to the USA, they just stuck a gross weight of 1,320 on them and really didn’t do anything.

“You read the accident statistics and landing-gear collapses on any number of these earlier European LSAs, and it’s pretty appalling. Jabiru, on the other hand, began this as a four-place airplane at a 1,600-pound gross weight. We don’t put the two back seats in, we reduce the gross weight rating from 1,600 to 1,320, we don’t make any structural or aerodynamic changes,” Krotje said.

The Jabiru is all fiberglass construction—no carbon fiber at all—using a material called Cormatt for strength that is sandwiched between two layers of fiberglass. Flight operations are not permitted above 104 degrees F. (Cormatt may be found in your bathtub as well.) The landing gear is made of more than 80 layers of unidirectional fiberglass, with no Cormatt. So far, there have been no landing-gear failures except when the aircraft ran off the runway or was used on an extremely rough surface. There have been three cases, out of 250 Jabirus flying either as kitplanes or LSAs in the United States, where the landing gear delaminated after a hard landing and let the aircraft droop on one side. But it didn’t break and the pilot could still taxi. In one case, a pilot used his extremely rough private runway one time too often, while in two other cases, pilots ran off runways into ditches. There are 2,000 Jabiru aircraft flying in 35 countries.

No airframe parachute is offered. “The airframe has been stressed to seven Gs at 1,540 pounds,” Bosman said. “It would be very tough to pull the wings off this aircraft. It’s been fully spin-tested to pass Australian certification standards, so it doesn’t need one [a parachute] for spin recovery. The chances of needing a chute are so very slim, we feel it’s not worth the added weight and expense.”

Costs

The base price for the J230 is $111,900 and includes basic round-dial instruments, an ELT, a Garmin SL40 radio, a pictorial turn-and-bank indicator, a cloth interior, and a PS Engineering PM1000 intercom. Most customers spend between $118,000 to $125,000 for the most commonly requested options. Four avionics package options are offered that range in cost from $8,500 to $20,400. Most buyers choose Panel 2, a $12,195 option that adds, in addition to the standard package, a dual Grand Rapids Technologies Sport electronic flight instruments display, a Grand Rapids Technologies GPS, a Grand Rapids Technologies 6000 engine instrument display, a Garmin GTX 327 transponder, and a larger analog airspeed indicator.

The J230-SP I flew was priced at $152,072, because it included nearly every available option, including XM Weather, a Garmin Mode S transponder, and the Garmin GDU 370 and 375 displays side by side (basically the Cessna Skycatcher panel). The aircraft I flew lacked two options, a Tanis engine heater ($725) and a Sensenich carbon fiber propeller ($1,150).

The J230-SP I flew was priced at $152,072, because it included nearly every available option, including XM Weather, a Garmin Mode S transponder, and the Garmin GDU 370 and 375 displays side by side (basically the Cessna Skycatcher panel). The aircraft I flew lacked two options, a Tanis engine heater ($725) and a Sensenich carbon fiber propeller ($1,150).

The six-cylinder Jabiru 3,300-cubic-centimeter engine is an air-cooled, direct-drive, horizontally opposed engine—a configuration familiar to most U.S. pilots. There’s no gearbox such as found on the Rotax engine commonly used in light sport aircraft. “For having sold 2,000 Jabiru engines, my phone could ring every day with engine problems, and it doesn’t,” Krotje said. “For years, I’ve had $150,000 in parts on the shelf, and for years my sales in a year were less than $20,000. It was hardly worth having a parts department.” That situation is changing now, only because many of the engines he sold are coming due for a 1,000-hour top overhaul.

To meet the ASTM industry standards for a 120-knot calibrated airspeed at maximum continuous power, the Jabiru sold in the United States is limited to 2,850 rpm. There’s no mechanical means used to limit the power to that setting, but the choice of propeller, its pitch, and the rigging of the aircraft are all designed to allow the aircraft to fly hands off at 120 knots—and no faster.

“Ah, ha,” you may be thinking, “I could just shove the throttle in and go faster.” Maybe not. The engine redline occurs at 3,300 rpm, so let’s say you decide to power up to 3,000 rpm. Two things happen: The aircraft accelerates to 127 knots, Bosman said, and it yaws to the left—an intentional incentive to discourage use of that power setting. In addition, you are above the average fuel burn of 4.8 to five gallons per hour at 2,850 rpm and have increased your operating cost.

Let’s say you try to find a way around the yaw at 3,000 rpm, and install the optional Trutrak DigiFlight IIG two-axis autopilot for $6,525. But you are foiled again. The autopilot is rigged to the ailerons, but not the rudder. The yaw continues. As the factory wished, you finally decide to cruise at the power setting shown on a placard in the airplane, 2,850 rpm, and accept the idea of traveling at the ASTM limit of 120 knots calibrated airspeed in cruise configuration.

What do customers say?

Gary Anderson of Carnelian Bay, California, bought the first Jabiru on the market in 2005 for $75,000. He added Garmin avionics and a Grand Rapids Technologies primary flight display. It was a J250 that has a larger wing and weighs more than the J230, but since he lives at 5,900 feet, he appreciates the wing. (The larger wing is discontinued because Jabiru owner Rod Stiff felt the aircraft got pushed around by turbulence too much, Bosman said. Stiff borrowed the design of a better- performing wing from his J400 model, lengthened it, added winglets, and got what he feels is a smoother ride.)

“My wife and I are long-distance bicyclists,” Anderson said. “The bicycle frames split and I can put them in the back of the airplane. I think it is the only light sport that you can do that with because of its cavernous baggage area.”

“My wife and I are long-distance bicyclists,” Anderson said. “The bicycle frames split and I can put them in the back of the airplane. I think it is the only light sport that you can do that with because of its cavernous baggage area.”

He took a three-week light sport repair course at Rainbow Aviation in Corning, California, allowing him to do all his own work on the aircraft. “I can do everything on that airplane that an airframe and powerplant mechanic can do, and I can also do the yearly condition inspection. My last [condition inspection] cost me about $40,” Anderson said.

Rich Carney, president of SRT Aviation in Mount Vernon, Illinois, said the $136,000 Jabiru 230 he bought in 2009 has handled the rigors of flight training well. It has all the options, such as XM Weather and traffic systems, to attract pilots who rent it for trips. “We do a 50-hour inspection one month and a 100-hour inspection the next month, and change the oil and put it right back in service. We are really happy with the way it is holding up.” He also loves the Jabiru engine for its smooth and quiet performance. When he wrote a business plan for the aircraft, he projected it would cost $59 an hour for fuel, oil, insurance, and maintenance. His projection was correct. He rents it for $95 an hour. Three or four sport pilots have completed their certificates in the aircraft, with an additional three ready for their private.

But how does it land?

Time was limited, since the aircraft I flew had to be on display at the U.S. Sport Aviation Expo in Sebring, Florida, less than an hour after my flight. Takeoff procedure is to lift the nose at 45 KIAS and wait for the aircraft to lift off on its own. Flaps are set at 10 degrees. Climb-out with flaps up is at 85 KIAS.

A quick check of stalls, steep turns, and slow flight found a stable aircraft with no naughty habits. But you want to know how it lands, right?

Jabiru USA pilot Nick Otterback suggested entering the pattern at Avon Park at 2,200 rpm, which results in 80 KIAS.

Abeam the touchdown point Otterback called for carburetor heat, idle power, and half flaps. Flaps are operated by an electric toggle switch with an infinite variety of settings between zero degrees and 30 degrees, depending on how long you hold the switch down. Holding the toggle switch for two seconds will result in moving the flaps 10 degrees downward. A five-second burst resulted in half flaps.

The airspeed slowed almost automatically to 70 KIAS for the base leg. The remaining flaps were added, which brought the aircraft to 60 KIAS, and we turned final to Runway 28. Winds were frisky, which had made sharp air-to-air photographs and smooth video difficult during the just-completed photo shoot.

The stable Jabiru reacted to crosswinds like a heavier aircraft, and needed only minor control inputs to stay on the centerline. Touchdown was smooth despite my lack of experience with the aircraft. “It’s a forgiving airplane,” said Otterback, who also works as an aircraft designer. “It’s not hard to fly.” While you would expect the demonstration pilot to say that, I had to agree.

A few years ago, the Jabiru appeared not yet ready for prime time because of questions about the fit and finish. Now, it’s ready for its close-up; but it’s not just another pretty face. It’s a hard-working airplane from the outback.

E-mail the author at [email protected].