The NeXT Beechjet

New power, panel, and pylon remans for the "old" Beechjet

Photograph Courtesy Nextant

Photography by Mike Fizer

It’s no secret that there are plenty of good used jets on the market today. Some are just plain excellent values for the owner-pilot, but others are particularly well-suited for remanufacturing and remarketing as rejuvenated airplanes. That’s the angle that Nextant Aerospace, of Cleveland, Ohio, is taking with its ambitious project to rework the Beechjet 400. The Beechjet began life as the Mitsubishi Diamond (type designator: MU-300), then was bought in 1986 by Beechcraft, renamed the Beechjet 400, and produced by the Beechcraft/Raytheon/Hawker Beechcraft Corporation through 2010. Some 900 Beechjets of varying nomenclature (the basic 400, the 400A, the Hawker 400XP) were built during its production run—among them were 180 ordered by the U.S. Air Force, dubbed T–1 Jayhawks, and used as trainers.

It’s no secret that there are plenty of good used jets on the market today. Some are just plain excellent values for the owner-pilot, but others are particularly well-suited for remanufacturing and remarketing as rejuvenated airplanes. That’s the angle that Nextant Aerospace, of Cleveland, Ohio, is taking with its ambitious project to rework the Beechjet 400. The Beechjet began life as the Mitsubishi Diamond (type designator: MU-300), then was bought in 1986 by Beechcraft, renamed the Beechjet 400, and produced by the Beechcraft/Raytheon/Hawker Beechcraft Corporation through 2010. Some 900 Beechjets of varying nomenclature (the basic 400, the 400A, the Hawker 400XP) were built during its production run—among them were 180 ordered by the U.S. Air Force, dubbed T–1 Jayhawks, and used as trainers.

Going digital—and green

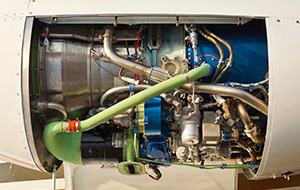

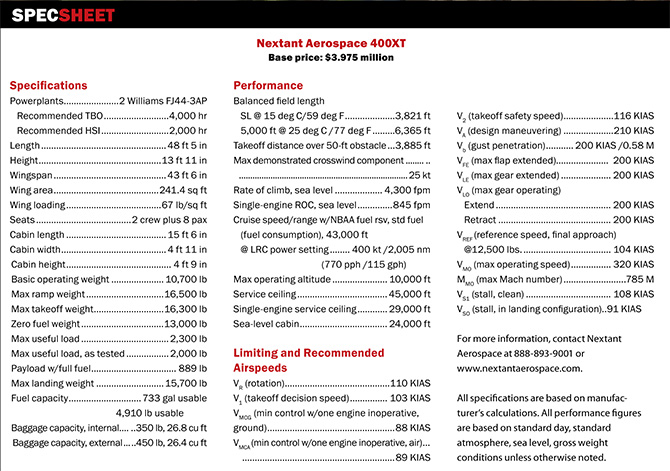

The 600-odd 400s and 400As now sell for between $900,000 and $3 million, and prices are dropping fast, according to the aircraft value reference guide Vref. Nextant’s goal is to capitalize on the Beechjet’s prime asset—its comfortable cabin—and boost its performance by swapping out the stock airplanes’ dated, thirsty, and less powerful (2,965 lbst) Pratt & Whitney JT15D-5 engines for a pair of 3,050 lbst Williams International FJ44-3AP engines. Nextant says that the FJ44s burn 32 percent less fuel than the old Pratts, weigh 240 pounds less, and have 4,000-hour TBOs—versus the JT15Ds’ 3,600 hours. Other benefits include FADEC controls and less greenhouse gas emissions. Nextant calls its remanufactured Beechjet the 400XT.

October 2011

Turbine Pilot Contents

- Turbine Intro: Powering into the future: Special section for the turbine inclined.

- The NeXT Beechjet: New power, panel, and pylon mods for the “old” Beechjet

- Routes Less Traveled: HondaJet sprints toward 2012 certification schedule

- Flying the Jumbo, Jumbo: Taking on the A380

- Honeywell’s SmartView Moves Ahead: Merging infrared with synthetic vision

Airframe changes

Nextant also makes aerodynamic enhancements associated with the new engine installations. For this, a computational fluid dynamics study was performed. To eliminate a drag-producing “choke point” between the stock airplane’s engine nacelles and the fuselage, Nextant designed engine pylons that are three inches wider and act as lifting bodies. This, Nextant says, does away with a supersonic shock wave that forms along the too-narrow gap. The wider pylons’ drag reduction amounts to 150 nm more range, the company says. Further drag reduction comes from Nextant’s new laminar-flow cowlings, plus a realignment of the engine axes.

Nextant also makes aerodynamic enhancements associated with the new engine installations. For this, a computational fluid dynamics study was performed. To eliminate a drag-producing “choke point” between the stock airplane’s engine nacelles and the fuselage, Nextant designed engine pylons that are three inches wider and act as lifting bodies. This, Nextant says, does away with a supersonic shock wave that forms along the too-narrow gap. The wider pylons’ drag reduction amounts to 150 nm more range, the company says. Further drag reduction comes from Nextant’s new laminar-flow cowlings, plus a realignment of the engine axes.

Beechjet engines are mounted with 3.5 degrees of “toe-out,” according to a Nextant official. In other words, if viewed from above, the engine axes

don’t parallel the fuselage centerline, and the engine inlets are aimed slightly outboard. To cut the resultant drag, Nextant remounts the engines with their inlets aimed 2.5 degrees inboard. As you might expect, V1 and VMC are affected by the wider pylons. V1 goes up by three knots, but only at the lightest weights. As for VMC, it’s lower than Vso at 13,500 pounds or greater.

Other upgrades include new engine mounts capable of withstanding 9.12 Gs (up from the Beechjet’s 8.5 Gs) and a Rockwell Collins Pro Line 21 avionics suite. Aircell satphone/internet/WiFi, TCAS II, XM WX datalink weather, and Rockwell Collins’ Venue cabin entertainment system are among the many options. Elliptical winglets and a three-seat, side-facing divan are other improvements on Nextant’s drawing boards.

A monster work package

The 400XT conversion is more than equipment upgrades. More than 6,000 man-hours are spent in putting the entire airplane in like-new condition. All airworthiness directives and mandatory service bulletins are complied with, the primary wiring harness is replaced, A though D phase inspections are performed, and any life-limited components are replaced with new or zero-timed parts.

The 400XT conversion is more than equipment upgrades. More than 6,000 man-hours are spent in putting the entire airplane in like-new condition. All airworthiness directives and mandatory service bulletins are complied with, the primary wiring harness is replaced, A though D phase inspections are performed, and any life-limited components are replaced with new or zero-timed parts.

Flight crew training is also part of the deal, with two pilots sent to CAE’s facility at the Dallas-Forth Worth Airport to earn type ratings. CAE will provide a dedicated full-motion Level D simulator for the 400XT program. The base price of the 400XT is $3.975 million.

Performance comparisons

The 400XT’s changes make for vast improvements over the standard 400 and 400A. The most dramatic is in the range department, with the XT able to fly four passengers 2,005 nm with 100-nm IFR fuel reserves. That beats a standard 400A/400XP by 50 percent, Nextant says. Takeoff and landing distances are roughly the same, but the 400XT’s high-speed cruise (460 knots) is 10 knots faster than the original airplane, and its long-range cruise speed (437 knots) is 23 knots faster. One-engine-inoperative climb rate is advertised as 845 fpm, where the stock Beechjet’s is a mere 305 fpm.

The 400XT’s changes make for vast improvements over the standard 400 and 400A. The most dramatic is in the range department, with the XT able to fly four passengers 2,005 nm with 100-nm IFR fuel reserves. That beats a standard 400A/400XP by 50 percent, Nextant says. Takeoff and landing distances are roughly the same, but the 400XT’s high-speed cruise (460 knots) is 10 knots faster than the original airplane, and its long-range cruise speed (437 knots) is 23 knots faster. One-engine-inoperative climb rate is advertised as 845 fpm, where the stock Beechjet’s is a mere 305 fpm.

Times to climb aren’t shabby, either: 22 minutes to reach FL430 versus 33 minutes. And Nextant promises a 30-percent fuel savings over the 400/400A, with a $2.13 cost per mile—based on a 1,000-nm trip with four passengers and Jet A priced at $4.90 per gallon. (The calculations were based on 2010’s average retail fuel prices).

Behind the wheel

Nextant kindly let me fly one of the first 400XTs—N402XT—from Wichita’s Mid-Continent Airport to AOPA’s home base at the Frederick, Maryland, Municipal Airport—a trip of about 950 nm. The plan was to cruise at FL430 on a more or less direct route, after passing by the Springfield, Missouri, VOR to avoid a large thunderstorm complex. It was a hot summer day, so temperatures were above standard (it was ISA +16 degrees Celsius at Wichita), from takeoff to touchdown.

Nextant kindly let me fly one of the first 400XTs—N402XT—from Wichita’s Mid-Continent Airport to AOPA’s home base at the Frederick, Maryland, Municipal Airport—a trip of about 950 nm. The plan was to cruise at FL430 on a more or less direct route, after passing by the Springfield, Missouri, VOR to avoid a large thunderstorm complex. It was a hot summer day, so temperatures were above standard (it was ISA +16 degrees Celsius at Wichita), from takeoff to touchdown.

Thanks to the FADECs, engine starts were super-simple (push the start button, monitor for start abnormalities), as was the takeoff (thrust levers full forward, with takeoff thrust limited to five minutes). With full fuel and four aboard, we weighed 15,300 pounds (1,000 pounds below max takeoff weight), our V1 was 107 KIAS, and VR was 112 KIAS. Passing through 14,000 feet, we were climbing at 270 KIAS and 1,800 fpm, and just 29 minutes after takeoff, we were at FL410—and this was with an ATC-mandated pause at FL360 for traffic.

At that altitude we were doing 432 KTAS, or 0.77 Mach, and burning 440 pph (about 67 gph) per side. At our final cruise altitude of FL430, we turned in 435 KTAS/0.76 Mach, but were burning 420 pph (about 62 gph) per engine. For stock Beechjet 400/400As, some say to flight plan for ballpark hourly fuel burns of 625 pph/93 gph per engine. Bear in mind that our power was set for a high-speed cruise.

At that altitude we were doing 432 KTAS, or 0.77 Mach, and burning 440 pph (about 67 gph) per side. At our final cruise altitude of FL430, we turned in 435 KTAS/0.76 Mach, but were burning 420 pph (about 62 gph) per engine. For stock Beechjet 400/400As, some say to flight plan for ballpark hourly fuel burns of 625 pph/93 gph per engine. Bear in mind that our power was set for a high-speed cruise.

By the time we were on final for Frederick, our weight was 13,000 pounds, which made for a VREF of 106 KIAS—and meant that we’d burned 2,300 pounds (about 343 gallons) of fuel during our two-hour, 29-minute flight. It also meant an average fuel burn of 920 pph (137 gallons)—about 300 pph (45 gallons) less than the unmodified Beechjets.

It’s at normal cruise power settings and longer range profiles that the XT demonstrates its greatest efficiencies. Typically, the XT will turn in average total fuel burns of 850 to 900 pph (126 to 134 gph) during a two-hour flight cruising at 0.73 Mach, Nextant says. An unmodified Beechjet burns about 1,250 to 1,300 pph (186 to 194 gph) at the same speed—a significant difference. On trips lasting four to five hours a Nextant Beechjet has a total fuel burn of just 700 pph (104 gph, or 52 gph per side) in the last two hours of flight, according to a spokesman. “And that’s assuming the unmodified airplane can even fly as long as four to five hours, which it can’t,” he added.

Next steps

Nextant had already received five orders for its 400XTs by mid-2011. More than 40 additional airplanes have been ordered by fractional operator Flight Options, and 11 retail customers have also signed up. Given the airplane’s fuel efficiency and range, plus its two-year warranty and seven service centers, the 400XT shows promise as an example of one of the more ambitious light-jet upgrades on the market today.

Email the author at tom.horne.aopa.org.