Aircraft engines are, for the most part, pretty simple pieces of equipment that are built to strict tolerances. The pistons get all the glory for producing the power, but it’s the crankshaft that enables them to do the work.

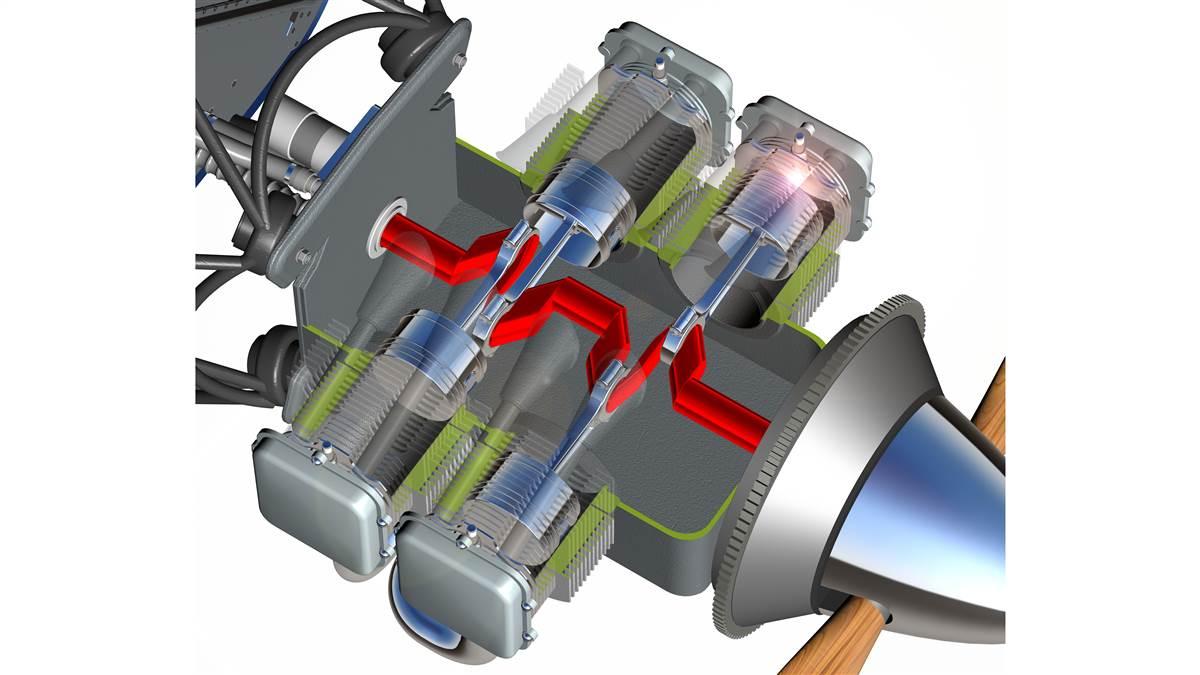

The operation of a four-stroke engine requires the pistons to move up and down within the cylinders at specific intervals. Keeping them going up and down on a consistent basis is the crankshaft’s job. This heavy piece of steel looks like a long rod that’s been dropped a few too many times. It rotates on a specific point, as a normal rod would, but swinging out on either end of those rotations is a series of crankpins or rod journals—one for each cylinder. Connecting rods attach the crankpins to the pistons.

The easiest way to imagine the motion is to put your hands in front of you and pretend you are pedaling a bicycle with your hands. This circular motion is similar to the crankpin, which allows the connecting rod and piston to move forward and back. The pistons provide the power, which drives the crankshaft, which is directly attached to the flywheel that turns the propeller.

A common crankshaft failure point is the bearings at the crankpins, which undergo significant stress as they are pulled and pushed back and forth thousands of times a minute.