Media noise accompanying the crossing of the English Channel July 9 and 10 by an electric-powered Cri-Cri and an Airbus E-Fan drowned out the quiet achievement of Elektra One Solar almost two weeks earlier. The aircraft, built by PC-Aero in Nesselwang, Germany—80 statute miles southwest of Munich—flew from Germany to Austria on a 2.5-hour flight, far longer than the 40-minute Channel crossings of the two later aircraft.

Elecktra One Solar made that flight on June 25 from Unterwossen, Germany, 60 miles southeast of Munich, to Lienz, Austria. On July 2 it flew from Lienz to Zell am See, Austria, on a two-hour flight in wind and turbulence.

The aircraft uses 280 solar cells to charge an 11.5-kilowatt battery package. The solar cells provided about 30 percent of the needed energy. The actual range of the aircraft is 270 nautical miles.

Not only did it battle headwinds and strong gusts on the return trip, it carried a three-dimension mapping camera and recorded both routes. It was accompanied by a chase aircraft.

PC-Aero will be in the news again in the future for each of three efforts now in progress. Flights for ultralight certification in Germany of Elektra One Solar are set to begin in September with certification expected by the end of 2015.

Construction of an Elektra Two Trainer is expected to start this year. It is a two- motor aircraft that promises an endurance of more than two hours and also is in the German ultralight category.

A model called Elektra Two Record has been designed, and molds for the two-seat tandem aircraft are complete. The Swiss company SolarXplorers has ordered it for a flight of as high as 75,000 feet. The first flight is planned for 2016 while the record flight is scheduled for 2017.

Elektra One Solar

Weight | 661 pounds

Max payload | 220 pounds

Max endurance | 5 hours

Cruising speed | 54 knots

Continuous motor power | 21 horsepower

Wing span | 43 feet

Email [email protected]

As you read this the Sun Flyer solar-electric is nearing completion 50 miles south of Nashville, Tennessee, at Arion Aircraft for flight tests this month. The aircraft was designed by Aero Electric Aircraft Corporation headed by George Bye, founder and executive chairman. If it looks familiar it’s because the design is licensed from PC-Aero’s Electra One. The $200,000 trainer could be delivered in two years depending on certification requirements.

Electric motor provides emergency power

Axter system adds 10 miles of options

By Alton K. Marsh

Researchers in Spain working at Axter Aerospacehave developed an electric motor that takes over from a failed piston engine and gives the pilot up to 10 nautical miles of additional flight. The system is certified in Spain, and in certification approval in Europe, for aircraft up to 1,650 pounds.

There are hopes to certify the system in the United States once partners are found. It can be used on Experimental category aircraft. It costs 18,700 euros, which on the day this was written was equivalent to $20,500.

It was co-developed with the Universidad Carlos III of Madrid. It can add 40 horsepower (30 kilowatts) to the gasoline- or diesel-powered engine for takeoff if needed. The combustion engine can recharge the electric system’s batteries.

In the case of an engine failure, the propeller is automatically disengaged from the combustion engine. The pilot simply throws a switch on the panel protected by a red cover. “[It is] easy to mount in 912 and 914 Rotax engines,” the company said in a slide presentation.

It is powered by a main controller and lithium batteries mounted in the aircraft cabin. The motor is mounted between the propeller spinner and the engine.

The test aircraft now certified in Spain with the system is the Tecnam P92, with EASA (European Aviation Safety Agency) certification pending. Axter Aerospace is backed by CT Engineering, one of 10 worldwide Tier One engineering service suppliers for the Airbus Group.

Email [email protected]

Photo courtesy Griswold Aviation

All business at Mach 4.0

Airbus patents a way to do it

What if you brought all the technology you’ve ever heard about—jets, ramjets, rockets—and stuck it in one airplane? You’d have a Mach 4.0 aircraft that doesn’t give a hoot about the sonic boom problem. That’s what scientists from Airbus Defense and Space have patented. Here’s how it works.

You arrive at the gate and your delta-winged steed is just outside, venting gases like a Saturn V headed to the moon. Its tanks contain liquid oxygen, liquid or slush hydrogen, and jet fuel. There are seats for 20 or room for two tons of cargo—OK, that may not seem like a lot. Still, this is stuff that absolutely, positively, has to get from Paris to San Francisco in three hours.

Jet engines, or just one engine (the design leaves the question open), extend beneath the fuselage for taxi and takeoff. After reaching a safe altitude, the pilot fires a rocket engine, or maybe it’s a rocket cluster, in the tail, being careful to retract the jet engines before reaching Mach 1.0. All the liquid oxygen and hydrogen slush, which Airbus calls “the fuel of the future,” is spent. You are headed straight up, in one of those astronaut couches in the Apollo capsule.

Bam! You break the sound barrier and a sonic boom spreads out in all directions, but because you are traveling vertically, it never reaches the ground. At 100,000 feet or 115,000 feet, the pilot noses over and lights the ramjets, stowing the rocket engine behind closed doors. There is still a sonic boom but you are over water. You snap a picture out the window with your phone.

Descent is, like the ascent, steep. The jet engines come out again. You enter the traffic flow and land. A few hours later your mega-billion-dollar business is concluded and you emerge from the darkened windows of the limo to enter the “ultra rapid air vehicle” and head home. The tail feathers look similar to those used by Scaled Composites SpaceshipOne. Could happen, especially since the idea is now patented with the United States Patent and Trademark Office. More likely, it’s not coming to an airport near you anytime soon.

The idea was proposed by Marco Prampolini, advanced project system engineer, and Yohann Coraboeuf of the Airbus Commercial Aircraft Equipment Business Unit. Fun to think about, at least. All you need do to become the pilot of this whiz plane is to head for the local airport and start work on that commercial pilot certificate.—AKM

Planning for the future

High school initiative under way

It’s back to school time all across the country and some teenagers are finding something new in their curriculum—aviation. As part of the nationwide emphasis on STEM learning—science, technology, engineering, and math—many schools are using aviation as a great learning tool. And AOPA is getting into the classroom with its High School Aviation Initiative.

Starting last fall, AOPA surveyed more than 180 high schools and education programs that include aviation as part of STEM-based learning programs to better understand their needs and the challenges they face. The results showed that high school aviation program leaders struggle with funding, resources, time, awareness, location, and logistics. AOPA formed a steering committee that includes well-respected leaders from a broad spectrum of aviation and aerospace to begin addressing these issues. A consortium of high school principals, program leaders, school superintendents, and guidance counselors will join AOPA in its AOPA High School Aviation Leadership Alliance, which will have its first meeting November 9 in Lakeland, Florida. If you’re an educator or aviation enthusiast who wants to help introduce aviation to students, plan to attend.

AOPA has contracted Pat Cwayna, CEO of the West Michigan Aviation Academy—a five-year-old aviation-focused high school he helped establish—to assist in the implementation of its high school initiative. He will serve as director of the leadership alliance.

“The one-day symposium will help us begin the conversation of how to grow GA through the high schools,” Cwayna said. “We want to bring the shortage of GA activity to the attention of principals and school leaders. We need to show them how GA can benefit their students and let them know the massive amount of jobs in aviation.”

In addition to the conference, AOPA will create a national aviation career club and create a booster program to help fund aviation STEM programs. Like Future Farmers of America or Junior Achievement, the career club will be a way for students to gain exposure to the working world of aviation and take part in learning opportunities beyond the classroom. The booster program will help provide start-up grants to launch new aviation study programs in high schools, create scholarship programs, and fund equipment such as flight simulators.

“There’s no magic bullet that will reverse decades of declining pilot numbers, but we’re committed to welcoming more people into aviation,” said AOPA President Mark Baker. “The AOPA High School Initiative is one more way we’re acting on that commitment.”

Interested?

If you would like to receive an invitation to attend the November 9 symposium, send an email.

Snoopy’s fantasy comes true

He really can fly a dog house

Former U.S. Air Force test pilot Otto Dieffenbach, once a banner-tow ground crew member in Ocean City, Maryland, makes fantasies fly. He’s flown a witch, Superman, and now Snoopy sitting atop his doghouse.

Former U.S. Air Force test pilot Otto Dieffenbach, once a banner-tow ground crew member in Ocean City, Maryland, makes fantasies fly. He’s flown a witch, Superman, and now Snoopy sitting atop his doghouse.

Many of his drone-like creations (actually they use flying surfaces and flight controls) have flown for promotional reasons and were created by his San Diego company, Flyguy Promotions. Not Snoopy. That was a personal project.

Dieffenbach traded his ground crew hours for flight lessons as a kid and got his private pilot certificate for single-engine land and sailplane aircraft. He has been too busy for the past few years to fly, but made a career of it in the Air Force, flying the McDonnell Douglas F–4 Phantom and later became a test pilot.

He calls his contraptions a “quad device” rather than a drone because they blend a great many aeronautical technologies, including thrust variation to change attitude. They all are home-built rather than based on a commercial drone. Each has a homebrew computer brain that aids stability. He recalls attempts by others to fly Snoopy atop his home—sorry, Snoopy, of course it’s a Sopwith Camel—that were unsuccessful in 1967. But with today’s technology, you can literally make a doghouse fly—I mean, camel. —AKM

Email [email protected]

Supersonic bizjets almost here?

This time they really mean it

By Alton K. Marsh

S-512 supersonic jet designed by Spike Aerospace.

Supersonic business jets have been on the edge of reality, according to aircraft manufacturers, for about eight years. Now several companies say they are close and in three, four—nine years, tops—a three-hour flight from New York to London via business jet will be possible. That sonic boom problem, engineers promise, will be minimized in order to win approval from the Environmental Protection Agency.

Spike Aerospace—headquartered in Boston and headed by engineers with experience at NASA as well as the aerospace industry—has just updated its S-512 design. Engines are now where the horizontal stabilizers were on the tail.

“The most noticeable change to the aircraft design is that the wings are now a modified delta wing,” the company said. According to Senior Engineer Anutosh Moitra, “the new delta wing of the S-512 delivers high aerodynamic efficiency and improved flight performance in both low-speed flight and supersonic cruise. The highly swept leading-edge reduces wave drag and consequently reduces fuel burn and increases range.

“We’ve also modified the tail to reduce drag and improve aircraft control in supersonic conditions. Improved stability characteristics of the new S-512 design allowed us to eliminate the horizontal tail, resulting in further reduction of drag and weight,” adds Moitra. Moitra has received awards from NASA and Boeing for past work.

Aerion Corporation located in Reno, Nevada, has been at it the longest, and also benefits not only from experienced leadership but from an association with Airbus Defense for its revamped model (based on customer feedback),the $120 million AS2. The company includes Mike Hinderberger, the former chief engineer for the Gulfstream G650, and John Holding, formerly a Bombardier Aerospace vice president and now senior advisor to Aerion. Joining recently was Ernest Edwards, formerly president of Embraer Executive Jets. The company is headed by investor and Chairman Robert Bass.

Aerion officials say on the company web site (aerionsupersonic.com) that their aircraft can fly at Mach 1.1 and 1.2 under the right atmospheric conditions, temperature, and wind, and sonic booms will not reach the ground. “This Mach cutoff cruise results from the normal physics of sonic boom propagation and not from any boom mitigation through aerodynamic technology,” the website says. Flight testing is needed to prove the theory. The aircraft will fly from New York to London in four hours and 19 minutes.

Richard Lugg of SonicStar says he can create a Mach 4.0 jet in a decade that will use advanced aerodynamics to control the sonic boom and fly from New York to London in two hours. Lugg is CEO of SonicBlue Aerospace, the company making the engines for SonicStar. He led research for Arthur D. Little and has a long record of propulsion and airframe innovation. You could leave London at breakfast time and arrive in New York at breakfast time. All that’s needed is to build it.

For that, you’ll need hybrid supersonic, non-afterburning engines; a hybrid double-delta supersonic laminar flow wing design; an 84,000-foot pressurized cabin; and electromagnetic drag reduction to reduce or eliminate the sonic boom and allow overland Mach 4.0 cruise—although speeds might need to be limited to Mach 3.8 because of aerothermodynamic heating.

What’s so difficult about that?

Email [email protected]

New Ascend Skyhawk is fully transformed

By Ian J. Twombly

You no longer have to pay around $400,000 for a “new” Cessna 172.

Yingling Aviation in Wichita is rebuilding the venerable Skyhawk with its new Ascend 172. The fully remanufactured airplanes are done in the spirit of AOPA’s Reimagined program, which takes strong legacy airframes and brings them up to modern standards. Yingling unveiled the Ascend 172 at the AOPA campus at EAA AirVenture in Oshkosh.

For the Ascend that means more than 40 work orders replacing or refurbishing everything from control cables to seat frames. Far from a new coat of paint and a new interior, the Ascend includes such items as new wiring, circuit breakers, pitot-static lines, engine accessories, windows, fiberglass, instruments, and fluid hoses. The engine and propeller are overhauled, a new flat metal panel is installed, and the seats are restyled.

“This program creates a pathway for those looking for a low-cost way to fly,” said Lynn Nichols, CEO of Yingling Aviation.

With a production run of more than 43,000 airplanes, there are plenty of donor airframes ready to be rebuilt.

One of the most striking things about the Ascend, as with AOPA’s Reimangined project, is the yellow paint. AOPA President Mark Baker said that it’s meant to grab attention. “I want these things to start a ramp conversation,” he said.

Yingling is offering the aircraft much like a factory new model, with a one-year warranty, and many options—including ADS-B Out, GPS, leather interior, and more. The base model costs $159,900.

Yingling is well positioned to execute on the Ascend. The company was Cessna’s first service center, it previously reassembled Cessna Skycatchers that were shipped from China, and it remains a major source of Cessna parts. —Ian J. Twombly

Sponsored by Breitling

This month in aviation October

October 22, 1900. The Wright brothers make their first glider flight.

October 4, 1904. The Wrights’ Flyer III covers 24.2 miles in 38 minutes and 3 seconds.

October 14-15, 1927. Dieudonné Costes and Joseph Le Brix make the first nonstop crossing of the South Atlantic.

October 4-5, 1931. First nonstop crossing of the Pacific by Clyde Pangborn and Hugh Herndon

October 3, 1942. First successful test flight of the V–2 rocket.

October 14, 1947. Capt. Charles E. Yeager flies faster than the speed of sound for the first time in a Bell X-1.

October 1, 1958. NASA becomes operational.

October 4, 1957. The Russians launch Sputnik I, the first artificial Earth satellite.

October 3, 1967. X–15 sets a speed record of 4,520 mph.

October 11-12, 1968. Apollo 7: The first manned Apollo mission.

October 28, 1972. The A300B1, the first airliner produced by Airbus Industries, makes its maiden flight.

October 3, 1991. Marta Bohm-Meyer becomes the first woman crew member of the SR–71 Blackbird.

October 24, 2003. British Airways’ Concorde supersonic jet makes its last flight.

October 4, 2004. Burt Rutan and the SpaceShipOne team capture the $10 million X Prize for the first private manned spacecraft to exceed an altitude of 328,000 feet twice in a 14-day period.

October 25, 2007. The Airbus A380 enters initial commercial service with Singapore Airlines.

October 14, 2012. Felix Baumgartner becomes the first man to break the sound barrier while freefalling, during his record-breaking skydive from the stratosphere.

Fuel

Pilots, town head to Swift fuel pumps

Homeowners discover airport fuel

By Alton K. Marsh

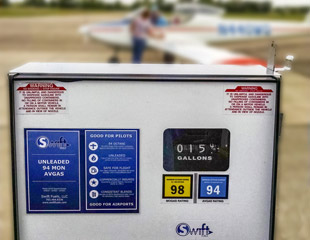

Pilots aren’t the only ones interested in Swift Fuels’ new replacement for auto fuel, the Unleaded 94 MON (motor octane number), now available at two Indiana airports and one in Michigan.

Pilots aren’t the only ones interested in Swift Fuels’ new replacement for auto fuel, the Unleaded 94 MON (motor octane number), now available at two Indiana airports and one in Michigan.

Craig Griswold, owner of Griswold Aviation at Brooks Field in Marshall, Michigan, said the small town heard about the new Swift fuel and bought it for boats, lawn mowers, weed whackers, and yard equipment. They know that auto gas with ethanol is bad for those engines, and that Swift Unleaded 94 has none. The fuel, used at the airport by only five pilots whose aircraft are approved for auto fuel, is a replacement for auto gas-approved airplanes, not aviation 100LL. Swift has candidate fuels in the FAA competition for a 100LL replacement, but evaluations are still in progress.

As head of the maintenance shop and a mechanic, Griswold said he has seen engines “gummed up” by auto gas containing ethanol. He estimates he has sold about 1,000 gallons to both pilots and the local community. “I’ve not had any negative comments,” he said. The airport has offered the fuel for five months. Griswold said 100LL at his airport on the day this was written was $4.80, while the Swift 94 was $4.15 per gallon. The fuel is a direct replacement for aircraft approved for auto fuel under a supplemental type certificate from Petersen Aviation.

At Anderson Municipal Airport, Anderson, Indiana, the Swift fuel is dispensed from an old pump once used for 80 octane aviation fuel, Airport Manager John Coon said. On the day this was written avgas was $5.05 per gallon while Swift fuel was $4.25 per gallon. Coon said the reaction from pilots is positive and some say their engines run cooler with it. It is colorless, so leaks do not leave blue streaks the way 100LL does. He has sold 650 gallons and said that is comparable to the amount of auto gas he sold before Swift 94 was offered.

Airplanes approved for auto gas and therefore eligible for Swift fuel include several models of Cessna, Piper, Beechcraft, Maule, and Mooney, aircraft that require fuel rated at or below 94 MON, including Light Sport engines such as the Rotax models.

The fuel is also available at Griffith-Merrillville Airport, Griffith, Indiana.

Swift officials said that more than 40 percent of the existing United States fleet is qualified for auto gas and, therefore, qualified for Swift Unleaded 94 MON.

Email [email protected]

Manufacturing

Recipe for an airplane

What if you could plug a pizza directly into the wall to cook without an oven? Scientists think they can make airplanes like that, according to an article in MIT Technology Review.

Today’s composite airplanes are made by popping composite material, formed in or wound around a mold, into a giant 750-degree-Fahrenheit oven costing tens of millions of dollars.

Aerospace engineers at MIT have now developed a carbon nanotube film that can accomplish the same end. When wrapped over a multilayer polymer composite and connected to an electrical power source to heat it up, the film stimulates the polymer to solidify.

It has been tested on composite material commonly used in airplanes and it worked, using only 1 percent as much energy as do ovens.

The new “out-of-oven” approach may offer a more direct energy-saving method to manufacture virtually any industrial composite, said Brian L. Wardle, a professor of aeronautics and astronautics at MIT.

“Typically, if you’re going to cook a fuselage for an Airbus A350 or Boeing 787, you’ve got about a four-story oven that’s tens of millions of dollars in infrastructure that you don’t need,” Wardle said. “Our technique puts the heat where it is needed, in direct contact with the part being assembled. Think of it as a self-heating pizza. Instead of an oven, you just plug the pizza into the wall and it cooks itself.”

Wardle says the nanotube film, which is just a fraction as thick as the diameter of a human hair, also is incredibly light. After it has fused the underlying polymer layers, it meshes with the composite, adding negligible weight.

All they have to do now is scale up the process to an actual airplane wing or fuselage. The idea was developed by graduate students Jeonyoon Lee and Itai Stein, plus Seth Kessler of Metis Design Corporation. —Alton K. Marsh

Engines

GE develops engine with dual personalities

General Electric has an “adaptive cycle engine” for jet fighters that is capable of two personalities; one is civil and promises fuel economy while the other is aggressive and is aimed at overpowering the enemy’s air force.

General Electric has an “adaptive cycle engine” for jet fighters that is capable of two personalities; one is civil and promises fuel economy while the other is aggressive and is aimed at overpowering the enemy’s air force.

The result is an engine with 30 percent greater range when it is happy, or 10 percent more thrust when it is angry.

“To put it simply, the adaptive cycle engine is a new architecture that takes the best of a commercial engine and combines it with the best of a fighter engine,” says Jed Cox, who leads the Adaptive Versatile Engine Technology project for the U.S. Air Force Research Lab. “So when I need high thrust, I can get high thrust. But when I don’t need high thrust, I can move into a super-fuel-efficient mode.”

Dave Jeffcoat, GE’s project manager, said the engine operates like a conventional fighter aircraft’s in a high-pressure-ratio, low-bypass mode, allowing pilots to maximize thrust. But during cruise or loiter conditions, it can transition to a high-bypass-ratio, low-pressure-ratio mode to be fuel efficient like a commercial engine.

The new design dramatically reduces the amount of heat the aircraft has to handle through use of ceramic matrix composites. It is claimed to mark the first rotating ceramic matrix composite parts in a jet engine.

“There have only been a few major leaps of this kind of change in the history of jet engine development,” said David Tweedie, manager of GE’s adaptive cycle engineering programs. “There was the leap from piston engines to turbojets, there was the leap from turbojets to turbofans. Now we’re making the leap from a conventional, fixed-cycle turbofan to a three-stream, adaptive-cycle engine. We’re working with the Air Force to set the architecture and enabling technologies that will be critical to the warfighter for the next 20, 30, or 40 years.” —AKM

Photo courtesy GE reports

Eating your way cross-country

The website 100dollarhamburger.com lists the best on-airport restaurants in the U.S.:

Special recognition

Breakfast. Nancy’s Air Field Café, Minute Man Air Field Airport (6B6), Stow, Massachusetts; 978-897-3934

Burger. Pilot Pete’s, Schaumburg Regional Airport (06C), Schaumburg, Illinois; 847-891-5100

Eastern BBQ (pig). Pik-N-Pig BBQ, Gilliam-McConnell Airfield Airport (5NC3), Carthage, North Carolina; 910-947-7591

Western BBQ (cow). Hard Eight BBQ Stephenville Clark Regional Airport (SEP), Stephenville, Texas; 254-968-5552

Chicken-fried steak. Southern Flyer Diner, Brenham Municipal Airport (11R), Brenham, Texas; 979-836-5462

Pizza.The Downwind Café, Spruce Creek Airport (7FL6), Port Orange, Florida; 386-756-8811

Steak. Harris Ranch Inn and Restaurant, Harris Ranch Airport (3O8), Coalinga, California; 800-942-2333

Pie. Spruce Goose Café, Jefferson County International Airport (0S9), Port Townsend, Washington; 360-385-3185

General category

The Mesa Grill, Sedona Airport (SEZ), Sedona, Arizona; 928-282-2400

Gaston’s Restaurant, Gaston’s Airport (3M0), Lakeview, Arkansas; 870-431-5203

The Perfect Landing, Centennial Airport (APA), Denver, Colorado; 303-649-4478

Jet Runway Café, Fort Lauderdale Executive Airport (FXE), Fort Lauderdale, Florida; 954-958-9900

Bistro Le Relais, Bowman Field Airport (LOU), Louisville, Kentucky; 502-451-9020

Sky Galley Inn, Cincinnati Municipal Airport (LUK), Cincinnati, Ohio; 513-321-3211

Tin Goose Diner, Erie-Ottawa Airport (PCW), Port Clinton, Ohio; 419-732-0236

Jake’s Joint, Ardmore Municipal Airport (ADM), Ardmore, Oklahoma; 580-389-5040

DeNunzio’s Italian Chophouse, Arnold Palmer Regional Airport (LBE), Latrobe, Pennsylvania; 724-539-3980

The Basin Harbor Resort Red Mill Restaurant, Basin Harbor Airport (B06), Vergennes, Vermont; 802-475-2317