Mentor Matters: In the frozen zone

Design and use of bleed-air and electric ice protection equipment

By Neil Singer

Perhaps ranking in desirability quotient only after their speed and range, the near-all-weather ability of jets is an attractive draw to the transitioning pilot. Weather that would ground a prudent piston pilot usually can be handled with careful planning and a dose of respect. In-flight icing can almost always be managed with aplomb by the new breed of light jets and their modern ice-protection systems.

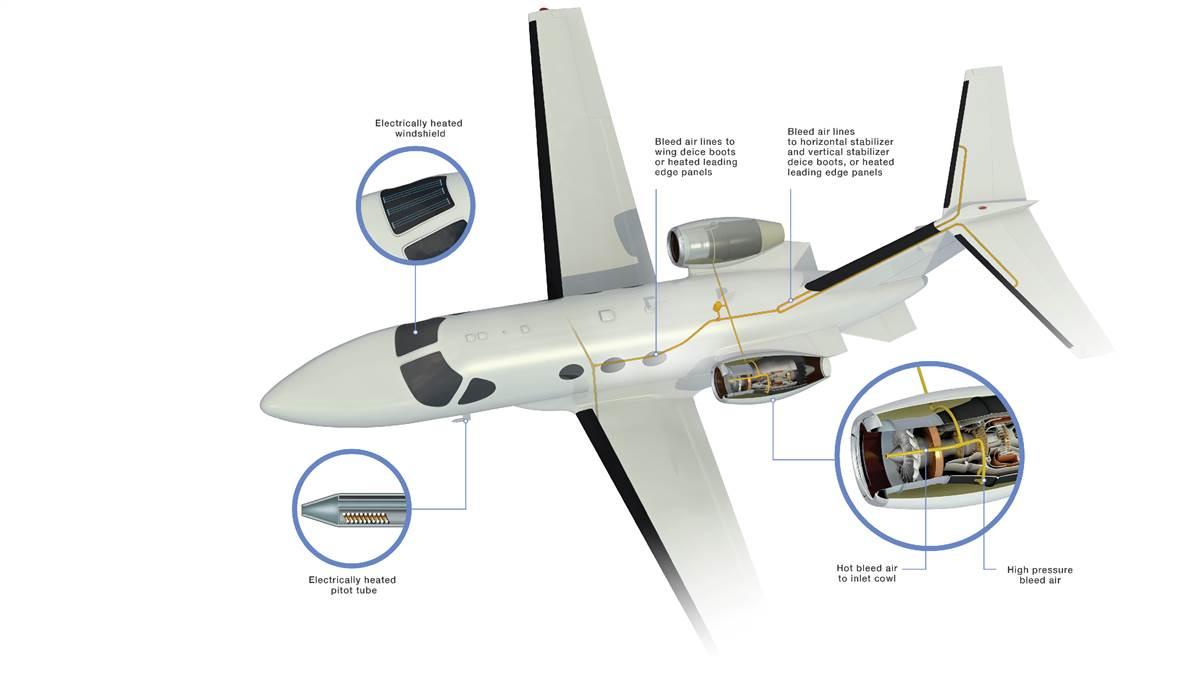

The design of wing and tail ice systems varies greatly; however, certain elements of ice protection have become standardized among various manufacturers. Probes—be they pitot, static, angle of attack, or temperature sensing—are electrically heated for the entire flight; set it and forget it. Bleed air heats engine cowlings; dense, hot air that has been compressed in the engine and extracted just before it would be mixed with fuel for combustion. This extremely hot air passes through a metal duct running around the cowl inlet before being vented overboard. The air is so hot that the cowl is heated to a point at which any moisture hitting it is instantly vaporized, preventing run-back freezing precipitation into the inlet.

With one exception, windshield ice-protection systems also have become standardized, with protection being provided by an electrically powered heating element embedded in the windshield itself. The exception is for Cessna Citation models that are derivatives of the original CitationJet (CJ)—currently the M2 and CJ3+. For these aircraft, and many “legacy” Citations, windshield ice protection is provided by hot bleed air ducted over the exterior of the windshield. Although this system certainly works well, it creates a noticeably noisier cockpit when switched on, and clears a smaller section of the windshield clear than an electrical system would.

With wing and tail protection, the system selected by the manufacturer is driven by the quantity of surplus bleed air available from the engine. The smallest of jet engines simply can’t spare the amount of bleed air that would be needed by a “hot-wing” system, or the thrust produced by the engine would drop too much. Any bleed air being used by the ice-protection system is air that is unavailable to be burned, and jet engines like to consume a lot of air. Thus, the smallest light jets in production use deicing boots on the wing and tail leading edges.

Although familiar to high-performance piston pilots, these deice boots are far more effective than those found on even heavy pistons. Automation of the system means that simply flipping a switch will cycle the boots on and off via a set cycle until deactivated—the pilot is freed from frequent visual checks of the wing and manual boot activation. Further, the bleed air used to inflate the boots is of higher pressure than a piston engine can produce, allowing for near-instant inflation, and more aggressive breaking and shedding of ice.

The use of bleed air by the hot-wing system reduces the thrust output of the engine, sometimes drasticallyThe engines that power larger jets can spare enough bleed air to keep the entire leading edge of the wing, and sometimes also the tail, at vaporizing temperature. These hot-wing systems have a large advantage over a boot system. In anything but the most extreme icing conditions the wing is kept entirely clear of ice, and experiences no degradation of lift whatsoever. No matter how effectively boots work, there usually is a small amount of intercycle ice adhering to the wing and causing a lift and drag penalty. For this reason, light jets with boots are forced to land roughly 20 knots faster at the same weight with any residual ice present, and experience an associated penalty to required landing distance.

This clean wing comes at a cost, however—the use of bleed air by the hot-wing system reduces the thrust output of the engine, sometimes drastically. In some jets, activating the full icing-protection system—engine, wing, and tail—can result in a noticeable deceleration of the aircraft, feeling similar to speed brakes being deployed. Climb rate plummets and, in an engine-out scenario with icing systems activated, terrain avoidance can become a much more difficult task. For one popular light jet, the engine-out ceiling at a heavy weight can drop from 24,000 feet to 10,000 feet with bleed-air ice-protection systems switched on—well below the MEAs in some parts of the country.

Proper operation of modern deice systems doesn’t require a large chunk of a pilot’s mental processing. Traditionally, hot systems—probes, windshields, and hot wings—were thought of as “anti-icing” systems to be activated before icing was encountered, while boots were thought of as “deicing” systems to be switched on after ice is observed. After decades of accidents attributed to pilots waiting too long to activate deice boots, even these systems are now starting to be treated as anti-icing systems, with pilots directed to proactively switch them on at or below given temperature thresholds, and not wait for any amount of ice accretion.

Besides switching on the protection at the appropriate time, pilots have one other important job to manage when in icing conditions: ensuring the ice protection sub-systems are fed with a sufficient supply of bleed air. The amount of surplus bleed air the engine can produce is a function of its thrust setting; at very low levels of thrust there typically isn’t enough bleed air to keep the hot areas properly hot. Depending on the aircraft, pilots may need to monitor engine-speed indications and be mindful in the descent of how far thrust is reduced.

In newer aircraft the engines’ FADECs (full authority digital engine controls) limit how low thrust can be set with icing activated. At times this can make for difficult speed control if the pilot hasn’t planned ahead. Descending at a high rate with a computer-mandated higher idle setting may make slowing impossible. So, while modern ice-protection systems have automated away many concerns present in legacy systems, a careful pilot is always mindful of the downsides of automation.

Neil Singer is a Master CFI with more than 8,500 flight hours in 15 years of flying.