AOPA 172 Sweepstakes: First things first

Yingling dives headfirst into your sweepstakes 172

Forty- and sometimes 50-knot headwinds hampered our progress as colleague Mark Evans and I plodded west. We landed to get avgas at Perry County Airport (I86) in New Lexington, Ohio, short of our planned fuel stop. In spite of a chart designation that fuel was available, we taxied off the runway to discover a deserted airport and no sign of fuel pumps. A phone call to the airport manager was quickly returned, and he came to open up a hangar, revealing the fuel truck stored inside.

Forty- and sometimes 50-knot headwinds hampered our progress as colleague Mark Evans and I plodded west. We landed to get avgas at Perry County Airport (I86) in New Lexington, Ohio, short of our planned fuel stop. In spite of a chart designation that fuel was available, we taxied off the runway to discover a deserted airport and no sign of fuel pumps. A phone call to the airport manager was quickly returned, and he came to open up a hangar, revealing the fuel truck stored inside.

A half-hour into the second leg, the attitude indicator and heading indicator went belly up. We now had no vacuum pump, but we still had a magnetic compass and charts available on our iPads. Clear skies accompanied the brutal headwinds, so we pushed onward. After a fuel stop at Virgil I. Grissom Municipal Airport (BFR) in Bedford, Indiana, we packed it in for the night at Sparta Community-Hunter Field Airport (SAR) in Sparta, Illinois. Checking the weather at Sparta, we learned that winds were projected to be blowing 40 to 50 knots at Wichita. The 172 is a tough little bird, but there are some things that needn’t be attempted at the very end of a long day of flying.

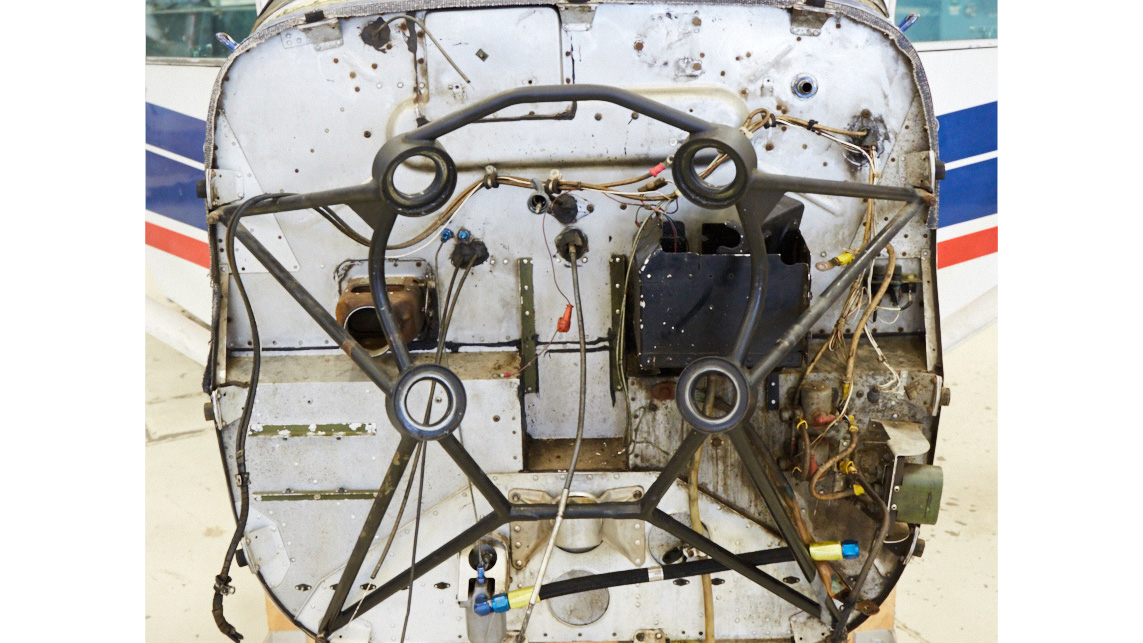

Once N739HW had taxied onto the ramp at Yingling Aviation’s headquarters at Wichita Dwight D. Eisenhower National Airport (ICT) in Wichita, Yingling technicians launched into action. They pulled out the avionics and removed as much of the interior as possible. Off came the landing gear; out came the control cables. Goodbye to the 160-horsepower Lycoming that was original to the airplane; goodbye to the propeller. No mere overhaul for our Sweepstakes 172—we’ll share details on the new engine in an upcoming issue.

The first phase of any Yingling Ascend 172 transformation involves a lot of detective work on the airframe as technicians assess what’s readily apparent to the casual observer, but also what’s beneath the skin. The 172 had some minor damage, and it’s not remarkable that corrosion would appear in an airplane that has sat for 10 years—even one that has been sheltered in a hangar.

Yingling’s team discovered damage on the trailing edge of the left aileron; dented skin on the left side of the elevator, and cracked skin on the right side; and skin damage on the rudder. Corrosion had crept inside both ailerons, as well as inside the flaps, the elevator, and the rudder.

All of those squawks have been or will be fixed. As you read this they most likely are finished, although a crack in the pilot door frame was awaiting parts from a kit, and Yingling Project Manager Steve Draher was pondering the best way to address a previous repair on the lower inside cowling. The area had been beefed up with honeycomb, but the patch is peeling. “So we’re looking at repairing or replacing—and the cost of a new bowl is pretty high,” Draher said. “We have to see which route we’re going to take: repair or find one. Then you have to unrivet it and install it, so we need to break down the cost on that one.” Draher sources parts and services with an eye toward keeping costs down, so I have no doubt that the solution he finds will be the right one for this project.

Email [email protected]

AOPA Members are automatically entered to win the AOPA 172 Sweepstakes. Members on Automatic Annual Renewal (AAR) receive additional entries.