Aircraft Maintenance: Engine overhaul leads to alternator failure

Tips to avoid maintenance-induced failures, Part 2

In this series of articles, we have been reviewing a series of component failures and safety issues caused by well-intended maintenance tasks. Our mission is to explore a examples in order to learn from the experience of others and to understand why it is so important for maintenance providers and owners to look at inspection and preventive maintenance situations with a more critical eye.

Case 2

The most invasive maintenance procedure routinely performed on general aviation aircraft is undoubtedly the engine overhaul. Every 2,000 flight hours or so, the engine and all of its accessories and related systems are removed from the aircraft, inspected, and overhauled or replaced as necessary. In many cases, the engine is running fine and the principal driving factor for this major surgery is simply the number on the tachometer reaching the manufacturer’s time between overhauls (TBO). In other cases, it is precipitated by cylinder issues producing low compressions or high oil usage and, in the smallest number of cases, the engine is overhauled because of a failure within the bottom end of the engine itself (the dreaded “making metal” scenario).

Regardless of the reason for the overhaul, it’s a big job, and making sure that the engine is properly overhauled and reinstalled in the aircraft is critical. Unfortunately, even the best overhaul facilities sometimes miss things that can cause failures down the road.

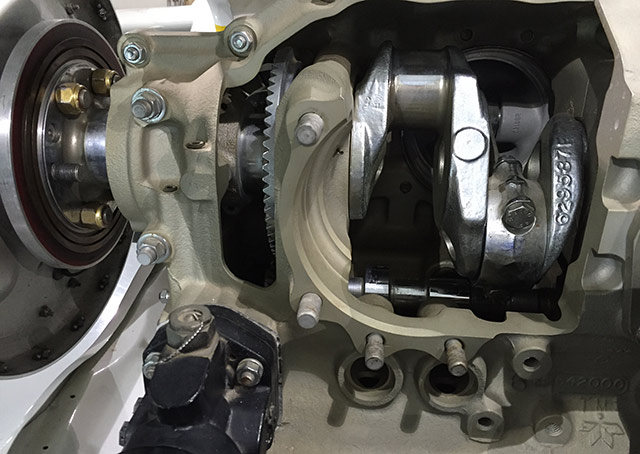

In this case, the engine was a turbocharged Continental Motors IO-550 installed in a Beechcraft A36 Bonanza. The overhaul facility was one of the most reputable in the country, one to which I would send my own engine without a second thought. The overhaul and installation went off without a hitch. All hoses and control cables were replaced, and components such as the starter, alternator, and vacuum pump were overhauled at the same time.

The aircraft was carefully test flown and monitored during the break-in period, and all seemed to be going well. After at least 40 hours with the new engine, the aircraft was flying in instrument meteorological conditions when the alternator bearings failed catastrophically, sending metal throughout the alternator, but thankfully not inside the engine case. The aircraft landed without incident.

Upon investigation, it was discovered that the alternator drive gear on the camshaft had significant wear runout on it, which theoretically stressed the alternator shaft and bearings until they failed. The installation shop and overhaul facility investigated the situation and were uncertain whether specific tolerances existed on the drive gear that should have been discovered during the overhaul of the camshaft and gears. Regardless of assignment of blame, all agreed that the engine had to be removed and have the suspect gear replaced. The overhaul facility stood behind the engine and paid for the costs of the work.

This particular engine was overhauled due to time in service reaching TBO and excessive oil usage. However, it was performing well when it was removed and the oil usage could be considered a cylinder problem—not necessarily justification for an engine overhaul (we will postpone the debate on when to overhaul an engine to a later time).

The point is that the failure can be clearly traced back to the overhaul of an engine that was otherwise healthy. The pilot’s skill in IMC with an electrical failure resulted in a safe outcome, but the result may not have been the same with a less experienced pilot.

As with the other cases in this series of articles, performing preventive or repair maintenance on an aircraft carries the risk of introducing a maintenance-induced failure. This case helps us understand why we need to be extremely careful and systemic with all aircraft maintenance. Attention to detail matters, and we should always carefully weigh the risks of the task with the benefits.

As we continue this series, we will review more interesting cases of maintenance-induced failures. If you have your own story of “well intentioned maintenance gone wrong,” please pass it along at [email protected]. Until then, Happy Flying!

Interested in aircraft maintenance? View the archives of Jeff Simon’s Aircraft Maintenance series.