Opinion: Stuck in Reykjavik

Remote diagnosis saves the day

Ademilola “Lola” Odujinrin has a passion for aviation. He’s 37 years old, resides in Nigeria with his wife and two school-age children, and was first bitten by the flying bug at age 7 when his airline-pilot uncle invited him onto an airliner flight deck (back in the days when such visits weren’t prohibited). Odujinrin earned his private pilot certificate at age 20. A decade later, he followed in his uncle’s footsteps to become a commercial pilot flying Boeing 737s.

Odujinrin also is an overachieving athlete and adventurer, who in 2010 cycled 2,000 miles from Morocco to London in 17 days. So it was no surprise when he announced his intention to become the first African to fly solo around the world. The aircraft Odujinrin chose for this mission was N313CD, a 2004 Cirrus SR22 that would be “tanked” to hold enough fuel to provide endurance of 17-plus hours, and equipped with survival gear, HF and satcom radios, and a bunch of GoPro cameras.

Organizing and obtaining funds for this mission (Project Transcend) took 10 years and was fraught with obstacles. The original plan was for the flight to start in Lagos, Nigeria, and proceed eastbound across Africa, India, Indonesia, Australia, Hawaii, the U.S. mainland, Canada, Iceland, Great Britain, Europe, and return to Lagos. However, cost constraints and operational considerations wound up dictating that the mission would instead originate and end in Washington, D.C.

Call for help

I first learned of Project Transcend over the July 4 weekend in 2016 while I was attending the Flying Physicians Association national convention in Minneapolis. Odujinrin contacted me on Saturday evening, asking for help. He told me he was on a round-the-world flight and made it as far as Reykjavik, Iceland, but had been stuck there for the past three days with an electrical problem that was eluding the mechanics there. We refer to situations like this as AOG—aircraft on ground.

About four hours into the seven-hour leg from Goose Bay, Labrador, to Reykjavik, Odujinrin noticed a flashing red warning on the Engine/Electrical page of the SR22’s Avidyne multifunction display (MFD), indicating that the E-BUS voltage was 13.0 volts. “E-BUS” refers to the SR22’s essential items bus, which powers the most critical instruments, avionics, and equipment; it’s supposed to be 28-plus volts. Odujinrin switched off all nonessential electrical loads and landed safely at Reykjavik. The anomalous E-BUS voltage indication was reproducible on the ground.

The Cirrus SR22 is an all-electric airplane. Its solid-state air data/attitude/heading reference system (ADAHRS), backup gyros, navigation, communications, and autopilot all depend on a properly functioning electrical system. An electrical malfunction has to be treated as a no-go item, especially for a transoceanic flight.

The SR22 electrical system is redundant and complex, employing dual batteries, dual alternators, and seven busses, all controlled by a complex master control unit (MCU). The local mechanics at Reykjavik—none of whom had any Cirrus-specific training or experience—performed basic functional checks on both batteries and both alternators, and reported that they all seemed to be working properly. They could not account for the low E-BUS voltage alarm on the MFD, and suspected some sort of MCU problem.

A replacement MCU would cost $3,000, and based on what he was hearing from the mechanics Odujinrin had no confidence that it would solve the problem. Besides, it was the Fourth of July weekend, so by the time a replacement MCU could be shipped to Iceland and installed in the aircraft, Odujinrin would be stuck in Reykjavik for at least another week.

Diagnosing the problem

I phoned my colleague Jeff Iskierka, explained Odujinrin’s predicament, and asked him to assist. Iskierka had been director of maintenance at a big Cirrus Service Center for 10 years before I hired him as my technical director. He knows the SR22 electrical system like the back of his hand.

I phoned my colleague Jeff Iskierka, explained Odujinrin’s predicament, and asked him to assist. Iskierka had been director of maintenance at a big Cirrus Service Center for 10 years before I hired him as my technical director. He knows the SR22 electrical system like the back of his hand.

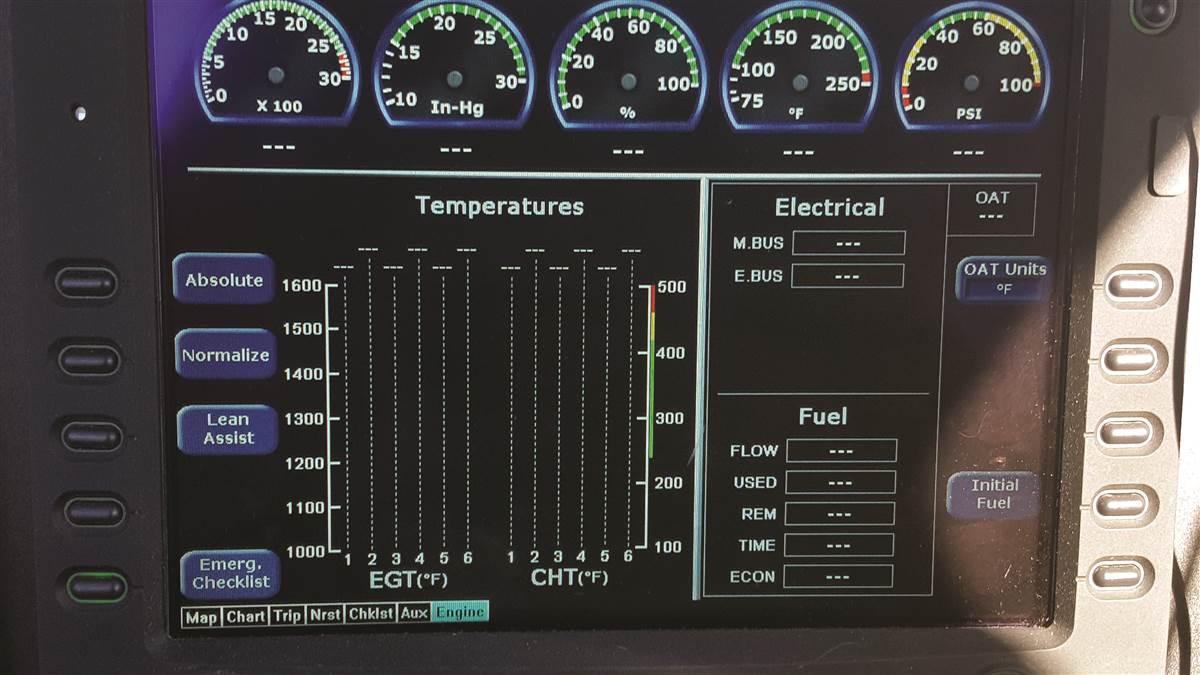

Iskierka emailed Odujinrin in Reykjavik to obtain the aircraft serial number, and pulled up the applicable electrical system schematics. Meantime, Odujinrin emailed Iskierka a GoPro video of exactly what he was seeing on his MFD display: an M-BUS (main bus) voltage indication of 28.7 volts, and a red E-BUS (emergency bus) voltage indication of 13.0 volts.

The M-BUS indication was normal; the E-BUS indication definitely wasn’t.

Iskierka told Odujinrin that the E-BUS voltage reading could not be correct. In the SR22 electrical system, the big number-one alternator feeds the main bus and a small number-two alternator feeds the emergency bus. The emergency bus is fed from the main bus through a silicon diode, so that if the number two alternator fails, the emergency bus will receive power from the number-one alternator through the diode. The voltage drop through the silicon diode is exactly 0.7 volts, so if the number two alternator fails, then the emergency bus will be 0.7 volts lower than the main bus. Since the M-BUS voltage was 28.7 volts, the E-BUS voltage could not drop below 28.0 volts.

Furthermore, if the E-BUS voltage really was 13.0 volts (as indicated on the MFD), none of the essential equipment powered from the emergency bus (attitude indicator, turn coordinator, PFD, com number one, and GPS number one) would be functioning. Yet Odujinrin confirmed that those items all seemed to be working normally. Therefore, Iskierka concluded, the essential bus voltage must be normal, and the MFD voltage indication must be bogus.

Iskierka advised Odujinrin that an MCU problem could not be responsible for this. Instead, the problem must be in a different black box altogether: the sensor interface unit (SIU). The SIU’s job is to receive analog signals from numerous sensors in the engine compartment (EGT, CHT, RPM, manifold pressure, fuel flow, oil pressure, oil temperature, and various electrical system voltages and currents) and convert them to digital information to be displayed by the MFD.

What’s the worst that could happen?

There seemed to be two ways forward: Odujinrin could spend another week in Reykjavik waiting for a replacement SIU to arrive and be installed by the local mechanics. Or he could fly his next leg from Iceland to Scotland with a known-bad SIU, disregard the bogus E-BUS voltage indication, and arrange to have the SIU replaced at a Cirrus Service Center in the United Kingdom.

Odujinrin wisely asked Iskierka the threshold question: “What’s the worst that could happen if I fly to Scotland with a failing SIU?” Worst case, Iskierka said, would be that the SIU might deteriorate further or even go completely inoperative, resulting in some or all of digital engine readouts on the MFD becoming erratic or changing to hyphens (“--”). However, the SR22 is equipped with backup analog “steam gauges” for critical engine parameters, and those analog instruments wouldn’t be affected by an SIU failure and should still provide accurate information. From an official FAA certification standpoint the SR22’s steam gauges are considered primary and the MFD readouts considered backups.

After processing all this information and sleeping on it overnight, Odujinrin made a command decision to launch for Scotland on Monday morning, July 4, satisfied that his electrical system was working properly and prepared for the possibility that his MFD readouts might not be trustworthy. On Monday evening, Iskierka and I received the following email: Dear Mike and Jeff, I could not go to bed without saying a massive thanks to both of you. Jeff said it all when I asked him what was the worst that could happen. He said I might lose all my digital readouts. That’s exactly what happened just 40 minutes into the four-hour leg from Iceland to Scotland. Knowing that this could happen, I was prepared for it, did not panic, and simply reverted to using the steam gauges as if I was flying my good old Cessna. I made it safely to Scotland, and I will have the SIU looked at when I get to London. Once again, I thank you. Best regards, Lola.

Odujinrin’s mission and location were unusual, but his predicament was not. I’d estimate that roughly half of AOG situations do not constitute a safety-of-flight issue, and, once diagnosed accurately, the airplane may prudently be flown home or—as in Odujinrin’s case—to another location where the necessary repairs can be accomplished conveniently, quickly, and competently. The other half of the time, safety concerns dictate repairs be made before further flight. In those cases, keep the work to the minimum of what’s safe and legal, and ideally defer any other work until you’re safely home and the aircraft is in the trusted hands of its regular mechanic.