Never Again: Check the Checklist

Engine failure after takeoff

By James Carter

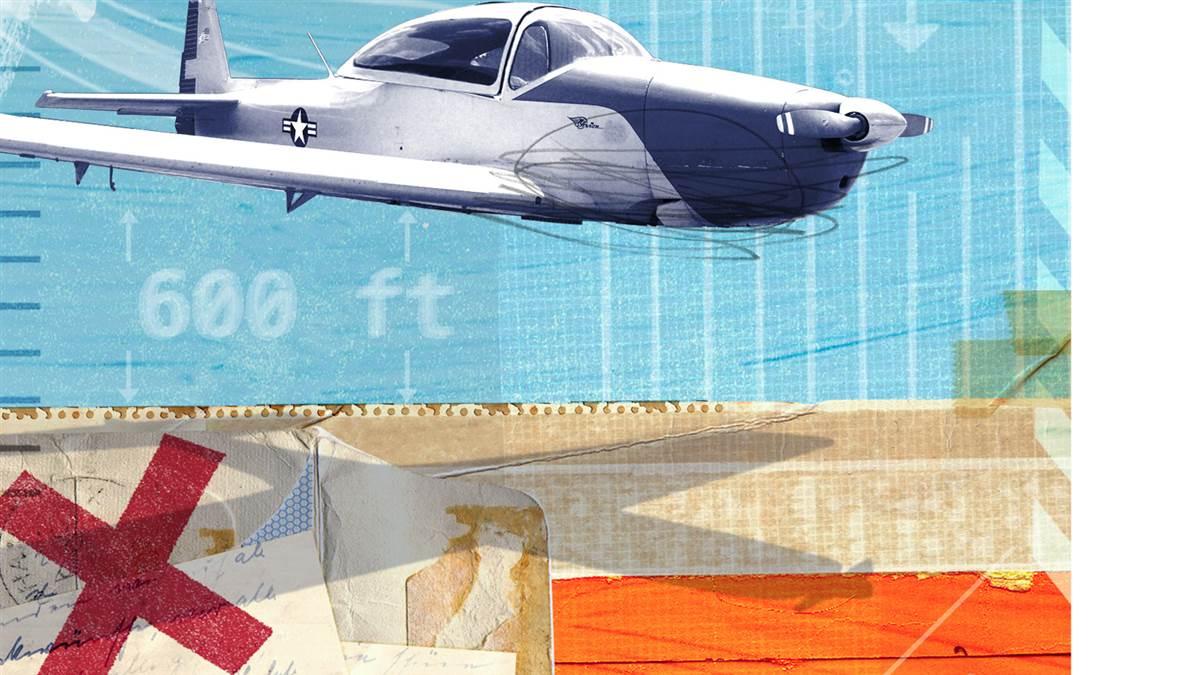

At 8:29:32 a.m. on December 15, 2016, after a thorough preflight and allowing the oil temperature to come up to 105 degrees Fahrenheit on my 1946 North American Navion, I made my departure announcement on the common traffic advisory frequency, eased the throttle open, validated good engine indications, and began my takeoff on Runway 36 at Bentonville, Arkansas (VBT). It was a cold, clear day with the wind out of the northeast at a gentle five to eight knots, and I was the first of three aircraft to depart. Less than a minute later I rolled to a stop on the runway facing south, after executing a turnback from 600 feet.

Thirty seconds after starting the takeoff, the gear drive shaft on the engine-driven fuel pump sheared and the engine abruptly quit while over the departure end numbers, 600 feet in the air. There is no place immediately north of Bentonville Municipal Airport on a workday to put a Navion down without serious damage and great risk to many others. The agility of the Navion allowed me to execute a steep nose-down rolling turn, make one radio call to keep others off the runway, put the gear back down at about 100 feet (Navion gear will free fall and lock into place without hydraulic pressure if necessary), turn off the master, and land firmly back on the runway 12 seconds later. I didn’t have time to reach for the main fuel valve on the cabin floor.

When I was instructing many years ago, we learned and taught that turnbacks were never to be attempted below 1,000 feet agl, and never on upwind. That is even more true today, especially with higher wing loading in modern high-performance aircraft. Years ago I practiced simple, low-stress aerobatics and became comfortable with unusual attitudes and extreme deck angles. While I had retracted the landing gear during the climb, I still had flaps in takeoff position, where they remained during the entire event. I knew my only option was to attempt a turnback. I immediately shoved the nose hard over and began a rapid roll to the right into the slight crosswind. The result was a pitch angle between 45 and 50 degrees below the horizon with a rate of turn that helped keep me close to the runway. The aircraft went from a heading of north to south in about nine seconds. These rapid control movements appeared almost violent to observers on the ground, but the stall and loss-of-control that too frequently makes the turnback fatal was avoided.

My Navion has one of the 1940s-technology engines—the Continental E-225 series—to which I added JPI’s EDM-930 engine monitor. The EDM-930 data dump of this brief flight provided the details I’ve described, including the fuel pressure going to zero PSI. It showed the fuel pressure starting to come up and reaching almost one PSI just as the master was turned off during the flare (it takes a minimum of 10 PSI to run the engine). I had to commit to the turnback, fly the aircraft, and extend the landing gear before I could reach for the fuel pump switch, so the auxiliary electric fuel pump didn’t have enough time to run. The electric fuel pump was probably on for less than two or three seconds. The mechanical fuel pump had 184 hours on it at time of failure. This fuel pump failure and engine stoppage occurred in an aircraft with redundant fuel pumps. Why it happened leads me to the lesson.

When I bought my Navion in August 2008, I’d never flown that make or model before but had been flying for more than 38 years and had accumulated sufficient time in multiple complex aircraft such that a checkout, a systems review, and participating in the acceptance annual inspection had me comfortable with the aircraft.

With older aircraft, many times you find that the operating manuals speak in generic terms and contain little information compared to what is available for most aircraft built after 1970. Especially on older aircraft, original or even reprint instruction manuals are not available, so new owners start with documentation provided by a previous owner—or provided by other operators of similar aircraft. I started with a set of original and owner-produced documents handed down by the previous owners and learned that was pretty much all that was available.

When I was checked out in the Navion, I used the provided checklist. A few items were unusual to me based on my experience with other older complex aircraft, but they were explained as being caused by “the pressure carburetor” or “the engine fuel system” or “that’s normal for the Navion.” One item was the electric auxiliary fuel pump operation. The checklist specified that the electric fuel pump was to be used only to prime the engine for start and to switch tanks in flight. I didn’t understand why, but I accepted it from the previous owner since he had flown the airplane that way for the many years he had it, and he had received those instructions from the previous owner of the aircraft.

If the electric fuel pump had been running during takeoff, I would have departed the pattern, switched it off while climbing to en route altitude, experienced the engine failure, turned the electric fuel pump back on, and returned to the airport for a normal landing.

I failed to seriously question the provided checklist when I came across an important memory item that differed 180 degrees from all my previous experience. I accepted what turned out to be a myth simply because I was new to the airplane; I placed too much trust in the previous owner’s experience; and I didn’t ask anyone else in the type club, American Navion Society and the Southern Navion Air Group, where there is a large accumulated knowledge base.

I didn’t question what was different and unusual; I didn’t check the checklist. The lesson I had to relearn is to take nothing at face value if it does not make sense. My checklist has now been expanded, modified, and vetted by a fellow Navion pilot with much more experience than I. You can bet I won’t have to learn this lesson yet again.

James Carter, CFII, is a Veterans Airlift Command and Angel Flight South Central volunteer pilot.