Ultimate Bonanza: As new at far less cost

‘The aircraft Textron should be building’

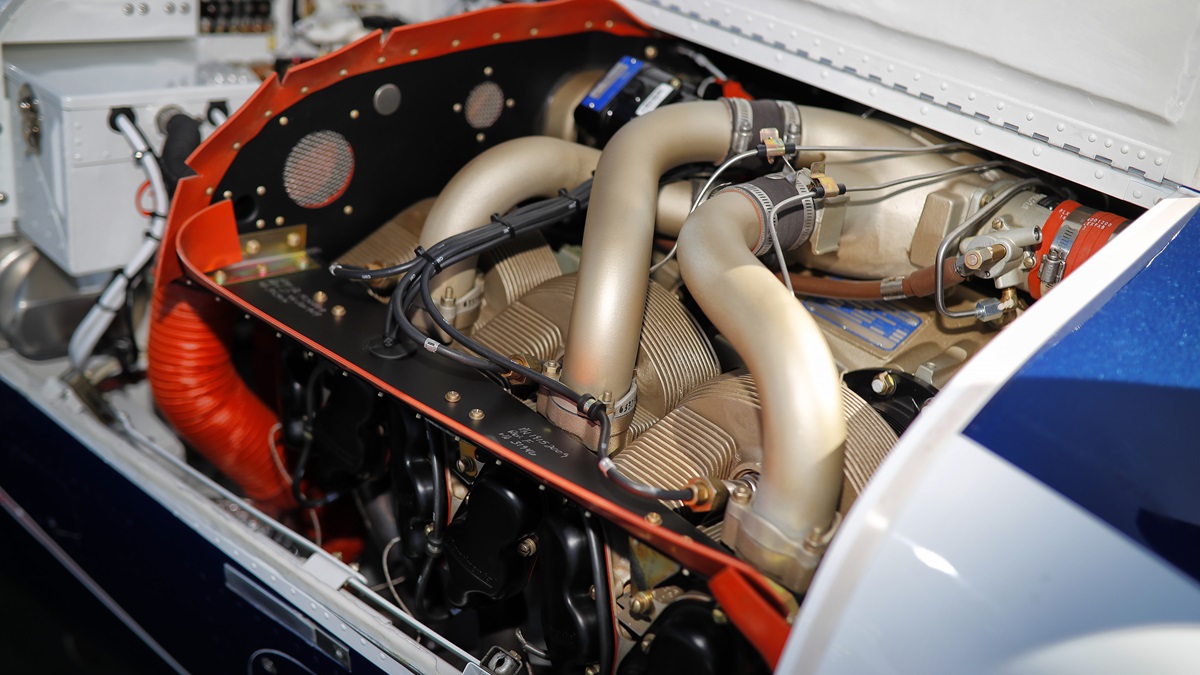

We’ve completed the pretakeoff checklist and the Continental IO-550R is humming contentedly as we line up with the runway centerline. Yet at the owner’s insistence, the cowl flaps are closed, and that’s triggered my self-preservation alarm. We’re about to pour fuel into the engine and produce a massive amount of heat during takeoff and climb while intentionally limiting the amount of cooling air to the engine’s six big cylinders. This seems like a terrible idea, despite owner Dan Blackwell’s assurances to the contrary.

“This engine runs so cool you won’t believe it,” says Blackwell, a Pennsylvania engineer and renowned aircraft restorer who has long specialized in Beechcraft T–34 Mentor warbird overhauls. Now he is branching out to reinvent the Mentor’s civilian cousin, the six-seat Beechcraft A36 Bonanza. “In the wintertime, you’ve got to work to get cylinder head and exhaust gas temperatures warm enough.”

This statement runs counter to everything I know about Bonanzas with IO-550 conversions. Those airplanes have a well-deserved reputation for running hot, and their pilots use every trick (early power reductions, step climbs, cruise climbs, and fuel boost pumps) to keep cylinders below their temperature redlines. The idea of intentionally taking off with cowl flaps closed seems dubious.

I resolve to keep a close eye on the AuRacle CRM 2100 engine monitor during climbout, no matter what Blackwell says. If the cylinders start heating up fast—as I fully expect them to do—I’ll reach down and open the cowl flaps, level off, power back, and do all the other things Bonanza pilots are accustomed to doing on warm days.

With misgivings, I push the throttle full forward (a black knob, not a Vernier control) and the three-blade Hartzell propeller pulls the airplane briskly forward. Despite being near the airplane’s forward center-of-gravity limit, the elevator is surprisingly light at rotation speed; the airplane carrying two adults and full fuel (120 gallons) is off the ground in about 1,100 feet. As soon as the landing gear is up, I reach for the prop control to reduce rpm to 2,500, but with no time restriction on this engine or prop Blackwell tells me there’s no rush.

“There’s really no reason to hurry,” he said. “You can keep climbing as long as you want to at this setting.”

The green bars on the engine monitor assure me the cylinder heads are well within their normal tolerances, despite the closed cowl flaps. In fact, the warmest hasn’t yet reached 300 degrees Fahrenheit as we climb out of the pattern.

Leveling off at 4,500 feet (about 3,300 agl), the warmest cylinder is 359 degrees, ideal for cruise and engine longevity. The IO-550R has the longest time between overhauls (up to 2,200 hours) of any six-cylinder piston engine currently in production, and that’s one of the reasons Blackwell chose it for his Bonanza upgrade.

“We put lots of these engines in T–34s and they’ve really proven themselves,” he said. “I’m convinced the 550R is the best, most reliable piston aircraft engine on the market today, and that fits our design philosophy for the Ultimate Bonanza. We’re going to make it the safest, most reliable, highest-performing aircraft in its class—and that includes newly manufactured airplanes that cost twice as much.”

Ideal candidate

Blackwell Aviation at Rostraver Airport (FWQ) just south of Pittsburgh is well known among T–34 Mentor aficionados for painstaking warbird restorations that are more than skin deep.

Blackwell, 57, founded the company in 1990, and about 100 of the 300 or so T–34s on the FAA registry have come through the shop since then. Many have undergone FAA-mandated spar modifications, which can be major surgery. Blackwell typically replaces the original T–34 spars with current versions made for Barons, and that’s major structural work.

Blackwell grew up in nearby Pittsburgh, attended Pennsylvania State University, and learned to fly in his teens. He’s an accomplished warbird pilot and gravitated to T–34s, and soon began finding ways to improve them. He’s written scores of technical articles about the two-seat military trainers and served for years as president of the T–34 Association.

Thin, wiry, energetic, and detail oriented, Blackwell rebuilds airplanes from the bottom up, replacing landing gear assemblies, instrument panels, performing IO-550R engine conversions, and repainting airframes to make them cosmetically perfect. He and four employees leave nothing untouched.

“It typically takes us about one year to completely gut and overhaul a T–34,” he said. “There’s a tremendous amount of common parts and similar systems in Beech products, so much of what we’ve learned over the years can be transferred to the A36 Bonanza.”

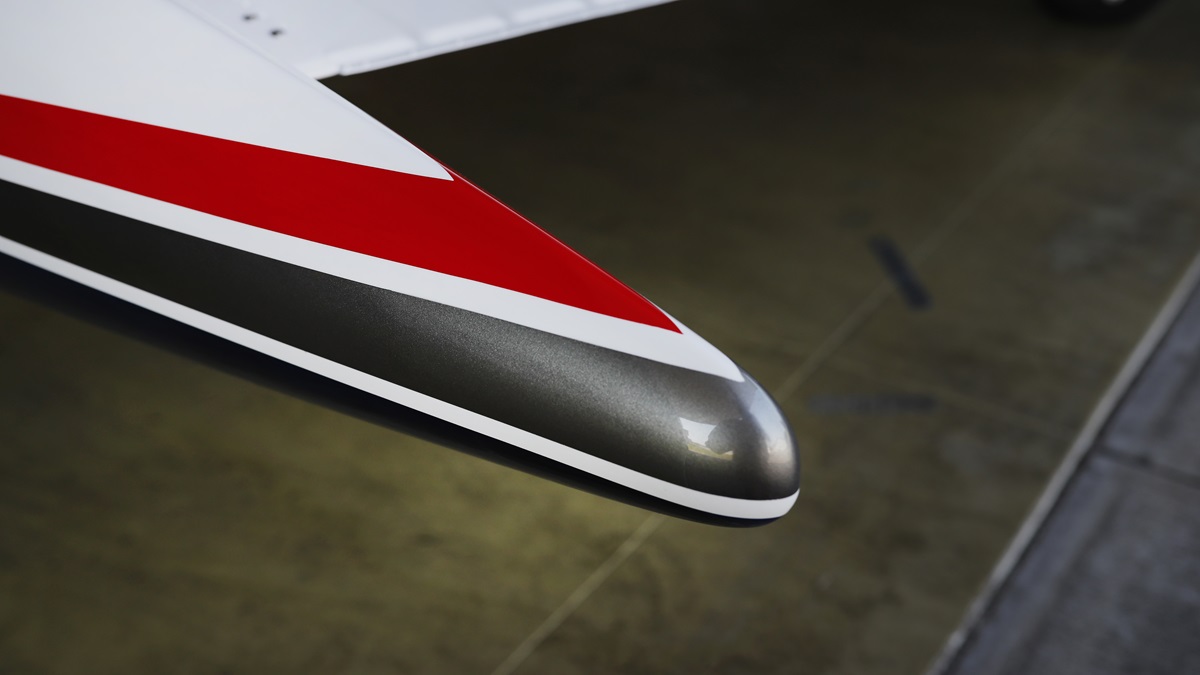

Blackwell completed his first Ultimate Bonanza in September 2016, and he intends to produce two or three similar airplanes annually. Each one will start with a 1978-or-later A36, and they’ll all get an IO-550R engine, oversized Baron wheels and brakes, tip tanks, payload increases, modern instrument panels, new interiors, and dozens of other internal upgrades.

There are also some things they won’t get. Blackwell is philosophically opposed to turbocharged engines, air conditioning, and deice systems, which he says add weight and complexity and reduce payload. “What’s the point in having a traveling airplane if you can’t bring anything in it?” he asks.

His opposition to deicing systems seems odd given his company’s Western Pennsylvania location, an area notorious for ice-filled clouds. But Blackwell argues deice systems create more trouble than they’re worth by making pilots overly confident that their single-engine airplanes can overcome adverse conditions.

Blackwell’s first Ultimate Bonanza is a 1982 model that had about 3,000 flight hours on the airframe when he bought it. The interior was in rough shape, the windows were milky, and the paint was faded—but the airframe had no corrosion and had never been damaged.

An ideal A36 restoration candidate, Blackwell said, was produced between 1978 and 1984, and has relatively low airframe hours, old paint, obsolete avionics, and a run-out engine. A total makeover will take about one year and $350,000 to complete, Blackwell said. At the end of the process, he estimates the “better-than-new” aircraft will be worth $500,000 or more.

“This is the aircraft Textron should be building,” he said. “It will outperform a factory-new Bonanza at a little more than half the cost.”

Smart improvements

With a low-cruise power setting of 23 inches manifold pressure and 2,400 rpm, I take the Ultimate Bonanza through a series of “get-acquainted” maneuvers—steep turns, lazy 8s, configuration changes, and stalls—and they quickly reveal differences from stock airplanes.

First, with all-new control linkages, pulleys, and cables, and expert rigging, this airplane restored just 60 flight hours ago is exceptionally well balanced. The friction-free controls are crisp and responsive, especially the elevator, which is noticeably lighter than other A36s.

Lots of piston airplanes claim to be “turbine smooth,” but this one is exceptionally so, and quiet. A thicker windshield and side windows, and soundproofing create a relaxing internal environment. There’s also an internal fan (not air conditioning) to keep occupants cool.

During steep turns, the modified, flat-top cowl is easy to align with the horizon, and sneaking a peek at the flight path marker on the Aspen 1000 primary flight display makes it easy to keep from gaining or losing altitude during 60-degree bank turns. Lazy 8s show that control pressures remain light and linear throughout the airplane’s normal range of speeds and bank angles.

Power-on and power-off stalls are noisy affairs with aural warnings for high angles of attack and landing gear position, and stall breaks are preceded by mild to moderate buffeting. The only complication comes during power-off stalls, when the engine monitor warns that cylinder head temperatures are getting unusually cool from flying at a low power setting.

The Ultimate Bonanza incorporates a modern instrument panel layout with smart human-factors improvements. Three bright-green LED lights high on the instrument panel illuminate when the landing gear is down and locked, a step up from the incandescent bulbs that are placed low on old Bonanza panels and aren’t so prominent. Two highly accurate Aerospace Logic resistive fuel gauges are a major improvement over the notoriously inaccurate float gauges from decades past. A cluster of annunciator lights is given prime panel real estate to get the pilot’s attention in case of system failures.

Even though this is a normally aspirated (nonturbocharged) engine, it does well in terms of speed and fuel efficiency above 10,000 feet, so the Ultimate Bonanza has a built-in oxygen system with a large, 76-cubic-foot tank. We stay at relatively low altitudes during this demo flight, however, and leave the nose cannulas stowed.

Returning to Rostraver Airport, I appreciate the A36’s relatively high landing gear extension speed (154 KIAS). Unlike earlier Bonanzas in which a tiny flap position indicator measures flap settings, the Ultimate Bonanza’s flap switch has two detents for approach (half) and landing (full) positions.

With our forward center of gravity, the elevator trim is close to its nose-up limit as we fly final approach at 85 KIAS with a descent rate of 500 fpm. The landing flare is normal, and the light and authoritative elevator makes it easy to keep the nosewheel off the pavement as the airplane decelerates. The oversized Baron tires make the rollout exceptionally smooth and braking highly effective.

Timeless airframes

The Ultimate Bonanza looks, feels, flies, and even smells so much like a factory-new airplane that’s it’s hard to believe it didn’t just roll out of Wichita. Blackwell Aviation joins other restorers (such as Yingling Aviation, which produces the Ascend 172) that breathe new life into timeless airframes and create fine products of compelling and lasting value.

The only problem with the Ultimate Bonanza is that Blackwell is a boutique firm that can only rebuild them in small batches. Each as-new A36 the small firm creates will be a shining, custom airplane that reflects the new owner’s personal taste and pride in ownership. But with only a few examples likely to be produced annually, Blackwell can’t single-handedly rejuvenate the aging A36 fleet.

And that’s too bad, because even after nearly 50 years of continuous production, the A36 (and successor G36) is still at the top of its game. Few, if any, other FAA-certified single-engine aircraft can travel as far, as fast, and as stylishly as this six-seat marvel.

Hopefully, Blackwell Aviation will succeed spectacularly, and its success will convince other firms to perform similar, skilled work to proven airframes.

Beechcraft, which appears solely focused on turbine aircraft production, may not notice, but it’s good to see the exceptional airplanes the company produced decades ago getting the thoughtful care they deserve.

Email [email protected]

SPEC SHEET

Beechcraft A36 Ultimate Bonanza

Price as tested: $490,000

Specifications

Powerplant | Continental IO-550R, 310 hp

Recommended TBO | 2,200 hrs

Propeller | Hartzell 3-blade, Super Scimitar

Length | 27 ft 10 in

Height | 8 ft 7 in

Wingspan | 34 ft 2 in

Wing area | 181 sq ft

Wing loading | 21.3 lb/sq ft

Power loading | 12 lb/hp

Seats | Up to 6

Cabin length | 152 in

Cabin width | 42 in

Cabin height | 50 in

Empty weight | 2,500 lb

Max ramp weight | 3,862 lb

Max gross weight | 3,850 lb

Optional | 4,050 lb

Useful load | 1,350 lb

Payload w/full fuel | 666 lb

Fuel capacity, std | 120 gal (114 gal usable), 720 lb (684 lb usable)

Oil capacity | 12 qt

Baggage capacity | 400 lb

Performance

Takeoff distance, ground roll | 850 ft

Takeoff distance over 50-ft obstacle | 1,930 ft

Rate of climb, sea level | 1,575 fpm

Max level speed, sea level | 188 kt

Cruise speed

@ 75% power, best economy | 182 kt 7,000 ft

@ 65% power, best economy | 172 kt 10,000 ft

@ 55% power, best economy | 167 kt 10,000 ft

Max range | 1,600 nm

Service ceiling | 19,500 ft

Landing distance over 50-ft obstacle | 1,450 ft

Landing distance, ground roll | 710 ft

Limiting and recommended airspeeds

VX (best angle of climb) | 80 KIAS

VY (best rate of climb) | 95 KIAS

VA (design maneuvering) | 140 KIAS

VLE (max gear extended) | 154 KIAS

VFE (max flap extended) | 123 KIAS

VNO (max structural cruising) | 166 KIAS

VNE (never exceed) | 205 KIAS

VS1 (stall, clean) | 59 KIAS

VSO (stall, in landing configuration) | 57 KIAS

For more information

Contact Blackwell Aviation, 724-379-8628, http://blackav.com.

Extra

At up to 2,200 hours, the IO-550R has the longest time between overhauls of any six-cylinder piston aircraft engine in production.