Savvy Maintenance: Actionable intelligence from big data

Comparing individual aircraft to others of their ilk

Report cards

In 2015, we started generating regular “report cards” (right) to subscribers who have been uploading enough engine-monitor data to the SavvyAnalysis platform to support statistically significant findings. These are Emailed to the owner, and analyze a dozen or so critical flight parameters related to performance, efficiency, and engine longevity. Most important, the report card compares those parameters with all the other aircraft we follow of the same type.

In the report, a “thermometer” graphically shows the minimum, maximum, and median value of each of the dozen analyzed parameters for an airplane, and how those compare with the distribution of median values observed in the entire cohort. Each thermometer is followed by textual commentary that advises whether we think the values for the subject aircraft are normal or abnormal, and—if abnormal—offers suggestions for corrective action.

The one pictured on this page is for a normally aspirated Cirrus SR22. It covers 27 flights that were uploaded to the SavvyAnalysis platform over the past year, and compares them with the corresponding parameters for 46,886 flights in the database for the 741 normally aspirated Cirrus SR22s that we follow. Let’s examine some of the thermometers from this Cirrus’s report card.

This aircraft cruised at a median 65.2-percent power, higher than 70 percent of the cohort, so I’m guessing the pilot wanted to fly fast. Interestingly, however, the aircraft’s median cruise speed of 164 KTAS was right in the middle (fiftieth percentile) of the cohort, and the median cruise altitude of roughly 7,000 feet msl was also right in the middle. The median fuel efficiency of 11.2 nautical miles per gallon wasn’t exactly stellar, falling in the thirty-eighth percentile. The aircraft’s cylinder head temperatures in climb and cruise are higher than normal (seventy-fifth and seventieth percentiles, respectively). These elevated temperatures don’t seem to be caused by any flaw of the aircraft’s cooling system, because the cylinder head temperature spread among the six cylinders is exceptionally low (twentieth percentile).

So this owner is cruising at higher power than most Cirrus SR22 pilots, getting mediocre fuel economy, running high cylinder head temperatures, and yet not getting any extra airspeed to show for it. Maybe he should have his aircraft rigging checked and work on his engine operating technique (as in, “lean of peak”). This is what I mean by “actionable intelligence.”

So this owner is cruising at higher power than most Cirrus SR22 pilots, getting mediocre fuel economy, running high cylinder head temperatures, and yet not getting any extra airspeed to show for it. Maybe he should have his aircraft rigging checked and work on his engine operating technique (as in, “lean of peak”). This is what I mean by “actionable intelligence.”

Exhaust valve failure

Many years ago, I discovered an interesting phenomenon: When exhaust valves start to burn and leak in piston aircraft engines, they often produce an oscillation in the cylinder’s exhaust gas temperature that can be used to detect incipient exhaust valve failure. The characteristic signature is subtle: a slow, rhythmic exhaust gas temperature oscillation with a period of roughly one cycle per minute and an amplitude of 30 to 50 degrees Fahrenheit (2 percent to 3 percent).

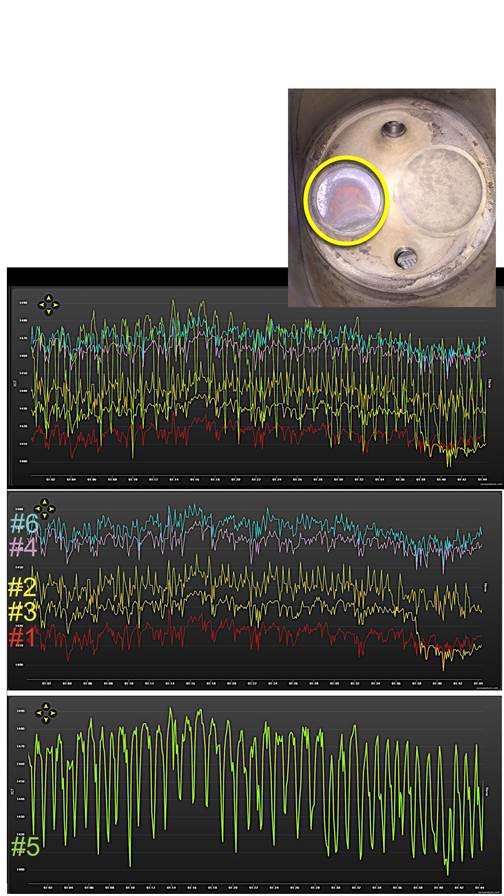

Two years ago, we enhanced the SavvyAnalysis platform to scan all uploaded data for such signatures so we could alert aircraft owners to them. We call this FEVA (Failing Exhaust Valve Analytics). Here’s a case involving a Cirrus SR22 (above).

Those EGT traces are very noisy; it’s hard to make sense of them. But if we split out the exhaust gas temperatures for cylinder number 5 from the pack, it’s obvious that there’s something different about that cylinder.

Cylinder number 5 is exhibiting precisely the slow, rhythmic oscillation indicative of a failing exhaust valve, while the other cylinders aren’t. We alerted the owner, and he Emailed us a photo showing what that exhaust valve looked like. If that valve had remained in service much longer, it would have failed outright.

A Cessna 340 also generated a FEVA alert (opposite page). The slow, rhythmic oscillation of EGT number 3 (yellow trace) is quite obvious, and is also reflected in a more subtle oscillation of TIT (white trace), while the other five cylinders look normal. The owner found (and photographed) a failed exhaust valve when cylinder number 3 was pulled.

Unfortunately, this Cessna 340’s owner wasn’t in the habit of uploading his data on a regular basis. He didn’t upload this data until after his engine started running rough, so he didn’t receive a FEVA alert in time to head off the valve failure. The moral of this story is obvious.

Mike Busch is an A&P/IA. Email [email protected]

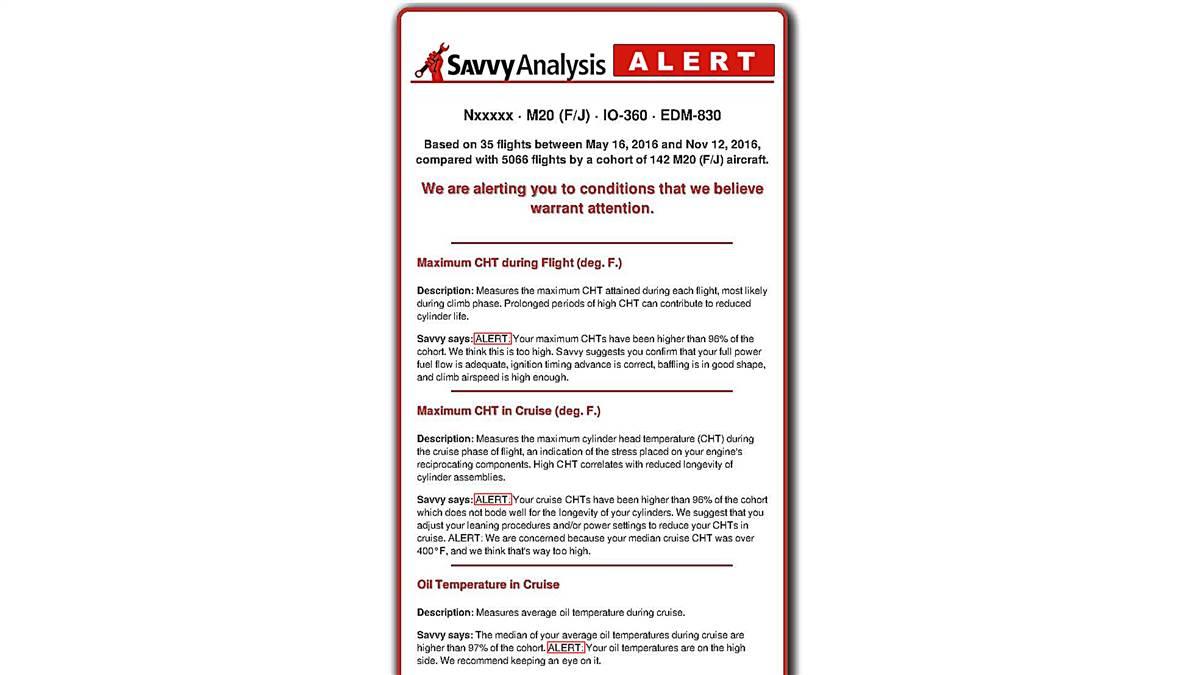

SavvyAnalysis generates report cards monthly, quarterly, or annually, depending on how active the aircraft is and how much data the owner uploads. But sometimes the software sees something in the data that is urgent and just can’t wait. That’s when the system Emails an alert to the owner. At right is an actual (de-identified) alert that was sent to the owner of a Mooney M20J alerting him that his cylinder head temperature and oil temperature were way too high (ninety-sixth and ninety-seventh percentile of the cohort), and suggesting he take corrective action right away.

SavvyAnalysis generates report cards monthly, quarterly, or annually, depending on how active the aircraft is and how much data the owner uploads. But sometimes the software sees something in the data that is urgent and just can’t wait. That’s when the system Emails an alert to the owner. At right is an actual (de-identified) alert that was sent to the owner of a Mooney M20J alerting him that his cylinder head temperature and oil temperature were way too high (ninety-sixth and ninety-seventh percentile of the cohort), and suggesting he take corrective action right away.