Craftsmanship: Modern Marvel

100 years of innovation at Hartzell Propeller

The arm doesn’t belong to an expert machinist—at least not the human kind. It’s a robotic arm, and the computer that serves as its brain and central nervous system grinds propeller blades better than the best machinist ever could.

At Harztell Propeller Inc.’s Piqua, Ohio, manufacturing facility, automation is everywhere. Instead of hundreds of people hunched over tools and tables, there’s the hum of a few dozen machines and the few dozen employees who maintain, feed, and monitor them.

For Hartzell, which celebrates its 100-year anniversary in 2017, the difference between where the company started and where it is today could not be more stark. The transformation has been evolutionary, but one of aviation’s oldest companies—one that started by supplying propellers to the Wright Aircraft Co.—today is one of its most technologically advanced.

Over the past 20 years Hartzell has steadily transitioned what had been a manual process of carving forged metal into blades and hubs to one that requires little human intervention. The factory is organized in a series of cells in which dozens of production steps happen within just a few machines. Each cell is organized based on material and broad category: aluminum hub, steel hub, blade grinding, and so on. Within each station the part is processed in, milled, analyzed in a digital quality control check, and then batched out. In some cases, a single machine can take care of multiple steps, and a robotic arm can carry a part between stations.

Machines that take raw aluminum and steel to create intricate propeller hubs are the most technically impressive part of the process, but the obvious visible manifestation of how far automation has come is in the blade-grinding station. In two broad steps a robotic arm picks up a hunk of forged aluminum, places it in a machine that roughly grinds it, and then places it back in a rack. Workers move the racks to the next cell, where another arm grabs the blade, swings it high like a modern samurai, and then gracefully places it against a grinding wheel. Regardless of the blade’s length, chord, or twist, the wheel grinds the blade to a perfect specification.

What’s happening at Hartzell is commonplace in many other manufacturing facilities outside of aviation. Trade gets more political attention, but most economists agree that automation has a greater impact in manufacturing employment levels. A paper from Ball State University calculated that trade accounted for 13 percent of manufacturing job losses, with the rest coming from productivity gains. Automation, in other words.

But for Hartzell President Joe Brown, improving efficiency is a way to save jobs by staying competitive. To Brown the best way to ensure the company remains in American hands and becomes outsource-proof is to ensure that it’s not a labor-based business. “We can’t compete on labor,” he says. Instead, he focuses on creating processes that intertwine skilled machinists with automated machinery. Despite the focus on doing more with fewer workers, Brown said the company hasn’t made any layoffs because of automation.

Storied history

With an aviation line of business that began in 1917, Hartzell is one of the oldest aviation companies in the world. Robert Hartzell had dreams of becoming a barnstormer, but his parents urged him to take another path. Hartzell’s father, George Hartzell, owned a lumber company and pioneered a method of heat-steaming walnut to produce wagons and other products. Along the way Robert became friends with Orville Wright (Dayton is an hour from Piqua). The airplanes of World War I were shedding propellers at a high rate because the wood would delaminate, and Wright encouraged Robert to follow his passion for aviation by using the wood-warping technique to make propellers. Hartzell’s Liberty propeller was used on thousands of Curtiss OX-5 engines, and was cut by hand.

The Hartzell family held on to the company until 1981, when it was sold to TRW, an aerospace conglomerate now part of Northrop Grumman. In 1987, James Brown Jr. purchased Hartzell. His son, Joe Brown, is the current president, and started working there in 1990.

Brown worked on the factory floor for 18 months, learning the various positions and getting to know the staff. “I learned a lot about the job—and about myself,” he says.

That daily grind paid off when, a few years later, Brown started the strategic objective of trying to win every contract he could with the best engineering and manufacturing, but at an efficiency that has enabled manufacturing to remain in Piqua well into the era of outsourcing.

As Brown walks the floor it’s obvious the workers respect him. Some have been with the company for decades, and Brown knows most by name. “Hey, have you been shooting?” he yells out to someone hunched over a computer. They chat for several minutes about the area’s many recreational shooting leagues. Brown rushes past another cell, then stops to ask how an older worker is feeling. “You look good!” he says.

At a time when many people change jobs about once every four years, scores of employees have worked at Hartzell for decades. Many work as families—father and son; brothers; even husband, wife, children, and in-laws. A few, such as Ed Barhorst, retired and then came back. He worked a total of 58 years. His brother Frank worked more than 50.

When Brown hustles past Paul Monnier in the anodizing area, he asks him why he loves working at Hartzell. Monnier says he trusts the company and feels grateful for the opportunity. Brown explains that despite the obvious implications to their jobs, the employees have embraced the push for automation, and the machinists have designed the processes in their areas. Brown starts to tear up. “Paul was on his hands and knees laying out tape for that cell,” he says.

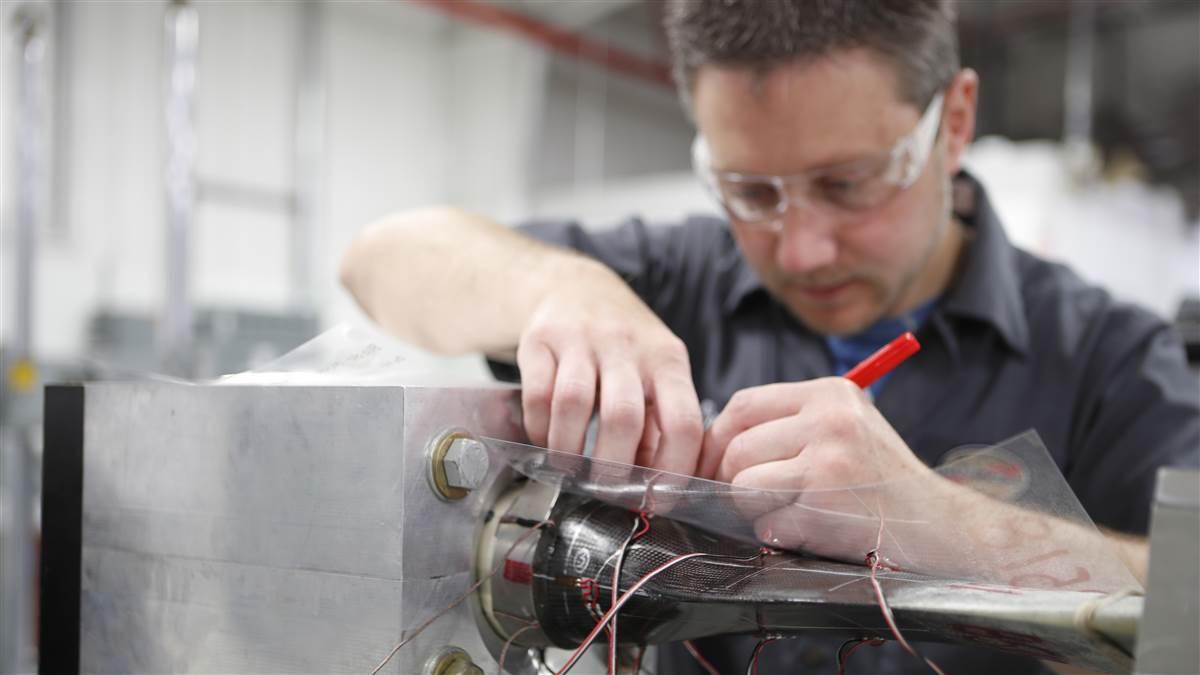

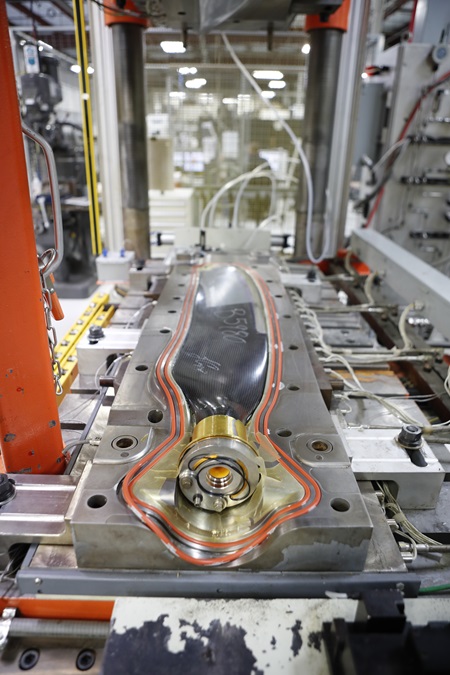

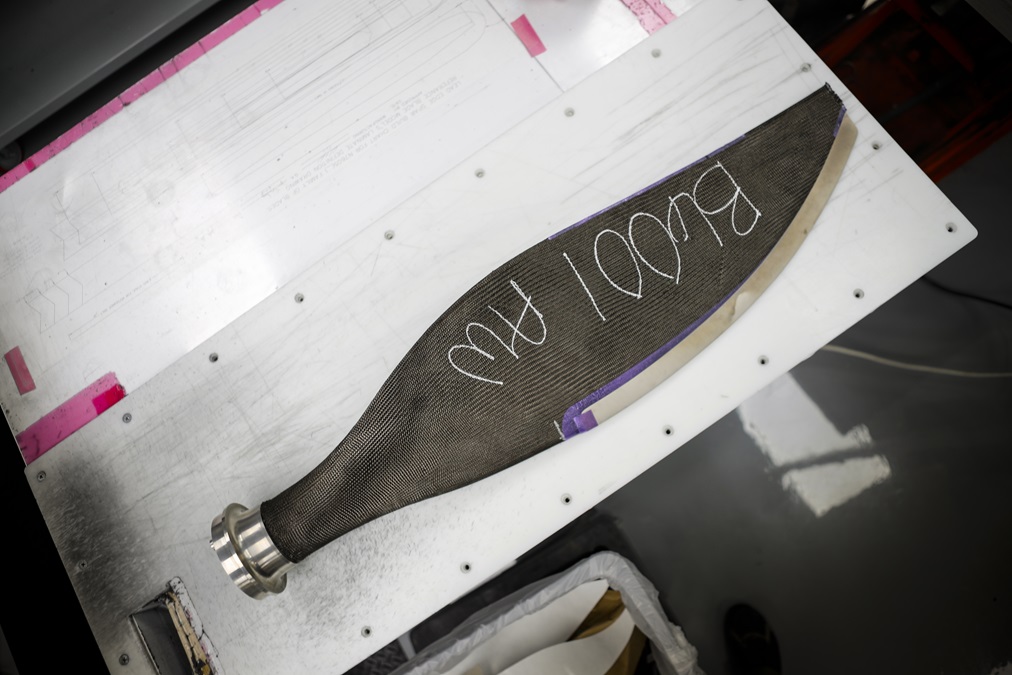

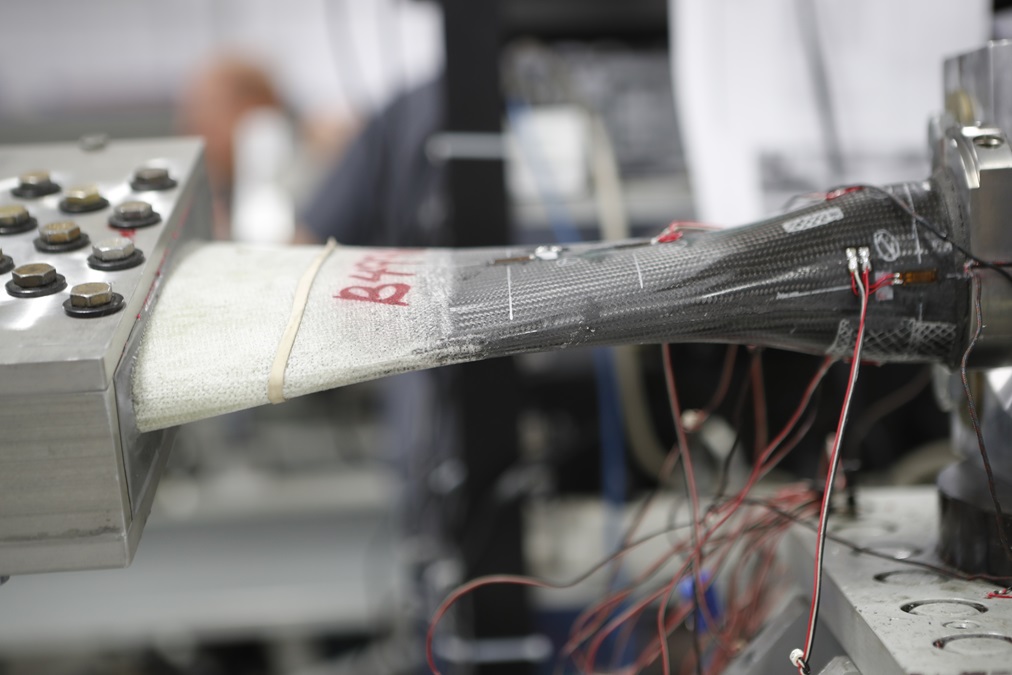

Not everything at Hartzell is automated. Composites now make up 30 percent of the company’s sales, and that remains a labor-intensive process. The production is housed in a different facility and has an entirely different vibe. It’s quiet, there’s an air-conditioned room for layup, and most of all, it’s a hands-on process.

Whereas in the metal manufacturing facility one machinist could be working four machines that put out a few dozen parts a day, at the composite facility, each blade is handcrafted. A worker lays up the foam core by hand, while another worker creates a carbon fiber and Kevlar sleeve from pieces that are cut on a machine—which is operated by a worker. The sleeve is fitted over the core by hand, and is carried across the shop where a worker cures each blade, one at a time. Each blade is then hand painted.

“We want to be late adopters but fast implementers,” Brown says of his approach to automation. If his staff can’t figure out how to make automation pay off after a few years, in reduced labor and a reduction in rejected parts, the company won’t invest in the technology. Those calculated decisions are evident in the two different paint booths. In the metal shop a robotic arm does the work.

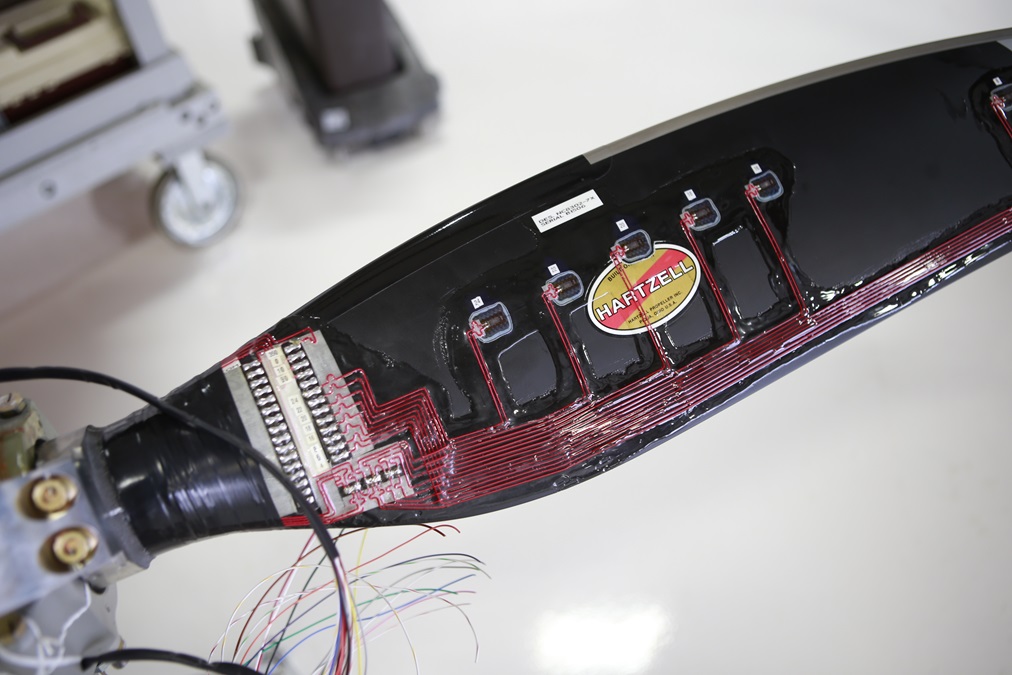

Regardless of which shop makes the blades, the final assembly happens at a small stand in the corner of the main facility. Two workers build up hubs, blades, anti-ice or deice, and spinner in a final hands-on gesture. They work quickly, assembling more than 500 different products, each with roughly 100 different parts. Some come through the cell only once a year or so, while others, such as those bound for new Cirrus aircraft, are an almost-daily occurrence. One of the last things the assemblers do is balance the propeller on a small machine that can detect the force of a dollar bill resting on a blade. It’s the last step in a process that brings life to a saying adorning every propeller since those destined for the Great War: “Built on honor.”

Email [email protected]