How It Works: Engine Baffles

Directing airflow like a pro

In modern piston aircraft, the engine is tightly cowled. Air flows into the cowling through openings in the nose bowl.

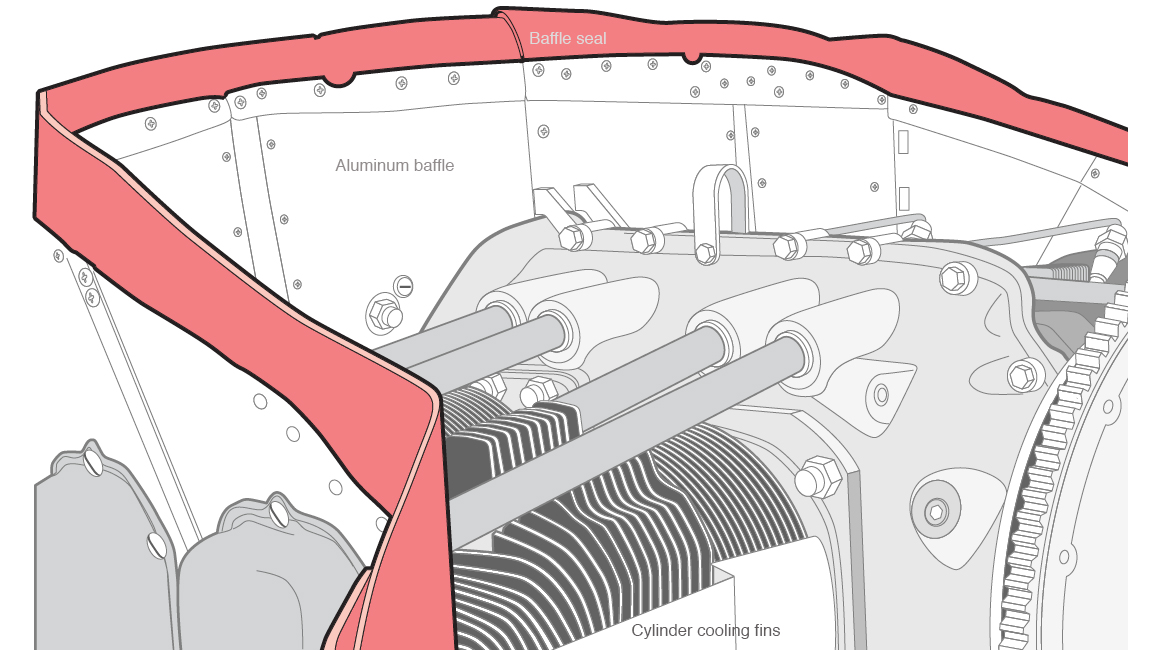

A system of rigid aluminum baffles and flexible baffle seals creates a chamber of high pressure above the cylinders, and another chamber of low pressure below the cylinders and behind the engine. They seal the gap on top of the engine to pressurize the air.

The baffles and baffle seals help to direct air over the cylinders from the high-pressure area to the low-pressure chamber, creating an airflow that travels from top to bottom (with a few exceptions, such as the Piper Navajo and Shrike Commander, because of their airframe design)—and eventually back out of the airplane through more openings in the cowl. Intercylinder baffles direct cooling air to the cylinder cooling fins.

The flexible seals close the gaps between the baffles and the cowling. If they age and become loose or brittle, they won’t keep air from leaking past the seal, and the result is poor cooling performance. You might notice an abnormally high cylinder-head temperature or oil temperature.

Baffles and baffle seals aren’t visible unless the cowling is off. Older seals are thin and black, whereas newer, silicone rubber seals are usually reddish orange.