Aircraft Maintenance: Pitot-static system failures

I recently spent some time chatting with Designated Pilot Examiner Greg Livernois about aircraft systems failures and the topics he routinely covers during his practical tests. Livernois brought up the subject of pitot-static system failures, mainly due the frequency of these types of failures and the importance of diagnosing and adapting to them.

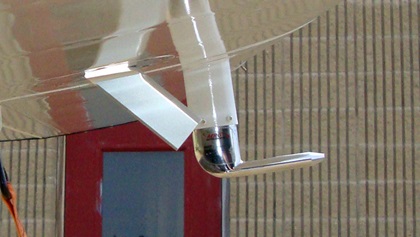

Pitot-static systems in general aviation aircraft are particularly vulnerable to failures because they lack the redundancy found in many other aircraft systems. Most GA aircraft only have a single pitot tube feeding the airspeed indicator that can be easily blocked by a mud dauber or similar insect. And, even if the aircraft has more than one static port, those can be easily blocked by water or ice, especially during the winter months. Tape gets left on the static ports after the airplane gets washed, pitot tube covers get left on, etc.

Know the symptoms

If you did have a blockage, would you recognize it? The airspeed indicator uses ram air from the pitot tube, compared with static air from the static vent(s) to display airspeed. A blocked pitot tube will only affect the airspeed indicator. Your airspeed will initially not increase as you accelerate down the runway. If the pitot tube and its drain hole are blocked, then as the aircraft climbs, the trapped air in the pitot system will be compared against decreasing air pressure in the static system. Your airspeed indication will rise, but it will not be accurate. If the aircraft descends, the airspeed indication will decrease. The instrument will, in effect, be acting like an altimeter, but without any frame of reference. If the pitot tube is blocked but its drain hole remains open, then the airspeed will just remain at zero.

The static system, on the other hand, affects your airspeed, altimeter, and vertical speed indicator (VSI) indications. A blocked static port will cause the altimeter and VSI to remain “frozen,” reporting the pressure trapped in the static system. The airspeed indicator will read lower than your actual airspeed when you fly above the altitude where the static port became blocked, and higher than your actual airspeed when you fly below the altitude where it became blocked. According to Livernois, who has experienced this failure firsthand, airspeed will drop to zero within the first couple thousand feet of your climb out.

Know your system

The key to preventing and surviving these failures is knowledge of your aircraft and its systems. Ask yourself these questions.

- If water gets into your static system, where does it go and how do you drain it?

- Do you have an alternate static source? Do you know how to use it?

- When is the last time you tested your pitot heat (if equipped)?

Make a plan

Before your next flight, take the time to make an action plan in the event of a failed pitot-static system. Quiz yourself on what you would see on your instruments for each of the failure modes and what you would do to react to the failure. Specifically, have a plan for the following:

- When to use pitot heat;

- How to judge airspeed without your airspeed indicator;

- When to use your alternate static source;

- When and how to “break the glass” on the VSI (as your last resort for an alternate static source); and

- How much to adjust your landing minimums.

A sunny day is fairly forgiving for most pitot-static system failures. However, things can get dangerous very quickly in instrument conditions if you haven’t prepared for the possibility of a failure. And you should be prepared, because pitot-static system failures are much more common than engine failures. All it takes is a bug looking for a new home or rainwater frozen in the wrong location, and you’ll need to put your plan into action. I’ve personally experienced two failures in my flying career; both on VFR flights and both uneventful. Take the time to improve your preflight, review your aircraft systems, and make an action plan. Even if you never have a pitot-static system failure, you’ll be a better pilot for it. Until next time, happy flying!