System rundown: Twin Commander 690 fuel system

Where gravity does the work

Built from 1972 to 1979, these Twin Commanders’ fuel systems take advantage of the airplane’s high-wing design—like the Aero Commander piston twins that preceded them. An interconnected network of 10 rubber-bladder fuel cells in each wing gravity-feeds fuel to two central tanks. One of these is in the center section of the wing, and it gravity-feeds to a central fuselage tank, where two boost pumps send fuel on to the engines, where engine-driven fuel pumps deliver it to the combustors. If one of those boost pumps fails, fuel will still be sent to the engines, although there’s a 25,000-foot maximum operating altitude limitation when using Jet-A. (It’s 15,000 feet when using Jet-B, and 10,000 feet if you’re forced to use avgas).

Built from 1972 to 1979, these Twin Commanders’ fuel systems take advantage of the airplane’s high-wing design—like the Aero Commander piston twins that preceded them. An interconnected network of 10 rubber-bladder fuel cells in each wing gravity-feeds fuel to two central tanks. One of these is in the center section of the wing, and it gravity-feeds to a central fuselage tank, where two boost pumps send fuel on to the engines, where engine-driven fuel pumps deliver it to the combustors. If one of those boost pumps fails, fuel will still be sent to the engines, although there’s a 25,000-foot maximum operating altitude limitation when using Jet-A. (It’s 15,000 feet when using Jet-B, and 10,000 feet if you’re forced to use avgas).

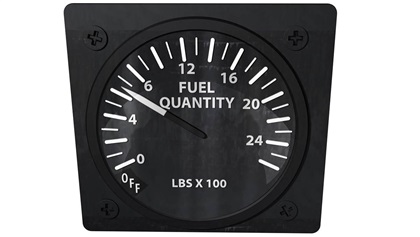

With the fuselage tank as the single point of fuel collection and delivery, there’s no need for fuel selectors—or multiple fuel gauges. That means there’s a single fuel gauge that shows the airplane’s total fuel load. This makes fuel management a breeze.

Sure, the 690s have check valves to prevent fuel from flowing the wrong way, fuel filters, sump drains, fuel vents, and shutoff valves—the same components you’d see in any airplane. And like any airplane there are also some gotchas. When gassing up, fill the center tank first, then alternate filling the wing tanks so that the fuel load is balanced. If you top off one wing while the other is low on fuel, a big gotcha can kick in: the airplane can tip over on the heavy wing. Also, because of fuel sloshing in the fuselage tank, it’s strongly advised to get the airplane on the ground should the low fuel warning light come on. It’s set to light up when fuel levels drop to 200 pounds/30 gallons or 300 pounds/45 gallons, depending on certain serial number ranges.

Another big gotcha strikes when fuel bladders need to be replaced. The new bladders have to be heated in warm water to make them pliable enough to be folded, carefully fed through their smallish access panels, and then unfolded and connected to the neighboring tanks. This is a job done mostly by feel and can rack up labor charges—especially if more than one bladder is involved.

Email [email protected]