Aircraft Maintenance: Professional aircraft detailing

I am usually a die-hard do-it-yourself person. Self-reliance produces experience and knowledge, and usually saves a good deal of money. So, when I brought my fiancée, Heidi, to pick up her car from the detailing shop recently, I was admittedly biased against having someone else “wash and wax” a car for over $200. When we arrived to pick up the car, however, my opinion changed. It looked brand new, inside and out, and the smile on Heidi’s face was worth far more than the money spent.

So, I decided to give myself a similar gift by getting my Bonanza detailed professionally. I never got around to removing the bugs and giving the airplane a decent cleaning before the cold weather set in, so the timing was perfect. Web searches and references in my area pointed me to New England Aircraft Detailing. I reached out to the owner, Mark Rubin, and made arrangements for the work to take place in my T-hangar (with the aid of several propane space heaters).

With the aircraft exterior clean, they began the process of removing the oxidation from the paint. Depending on the situation, they use their expertise to choose from a variety of cutting and polishing compounds. The goal is to remove as little paint as possible; just enough to get past the surface scratches, oxidation, and stains. They start with the mildest compound and progress to harsher compounds as needed until the area is restored. Then they work back up through progressively finer levels of compound until the finish is as smooth as glass. Their use of power tools is limited, and they are careful to avoid going over the rivets. I was happy to see this because I’ve personally witnessed the damage that a traditional automotive buffer can do on an aircraft by literally buffing the paint off of the rivet heads.

During this process, David worked through the entire interior of the aircraft, cleaning the carpet and leather seats and then applying a leather conditioner. Mike worked on the polished aluminum spinner until I could see my reflection from across the hangar.

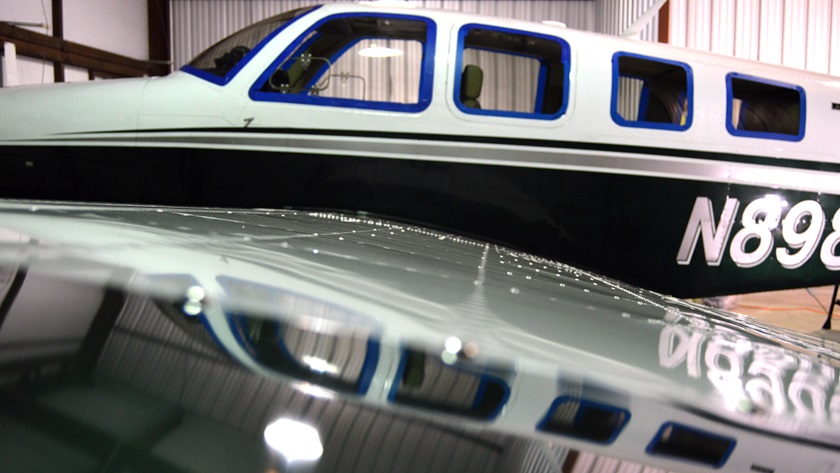

The last step of the process was probably the most transformative: ceramic coating of the paint. This fairly new process was popularized by car collectors, then utilized by jet aircraft owners to protect the paint from exhaust staining. It’s only recently migrated to general aviation aircraft because, at about $150 per 50ml bottle, the coating itself is extremely expensive. It can only be applied to clean and prepared surfaces and requires some degree of skill to apply properly. That said, I can personally attest that the results are impressive. Following the coating, the paint took on a “wet look” that I’m told will last for three to five years and will make future bug removal a breeze. The entire process on my Bonanza took two days in total and I couldn’t be happier. I’ll be sure to provide follow-up on my experience as time passes.

Pro tips from New England Aircraft Detailing's Mark Rubin

- Never use any type of power washer on an aircraft.

- Never use any household products, only specialty products.

- Be extremely careful with power buffers and avoid automotive orbital buffers.

- Always use the most gentle compound required to remove stains and oxidation.

- Take your time.

- Be sure to check the rules at your airport before you begin washing.

Supplies used

- RealClean Products—Drywash Pro, SD20 Degreaser

- Granitize Products—Aluminum Polish

- California Custom—Purple Metal Polish

- SoClear Technologies—MicroKut MK-100, 200, 300

- Solo Polishing Compound

- Sapphire V1 Nano Ceramic Protective Coating

- Perrone Leather Cleaner and Conditioner

Standing in the hangar, I admired the results of two full days of work by the team of four technicians from New England Aircraft Detailing. I could barely keep my eyes off the reflections in the refinished paint of my aircraft. While I love the satisfaction of doing my own maintenance work, Heidi was right: Sometimes it pays to let the professionals take a turn where manpower and expertise can make a difference. And, after all, the best gifts can be the ones we give ourselves. Until next time…happy flying!