How it works: Seeing your way clear

Some forward visibility is better than none

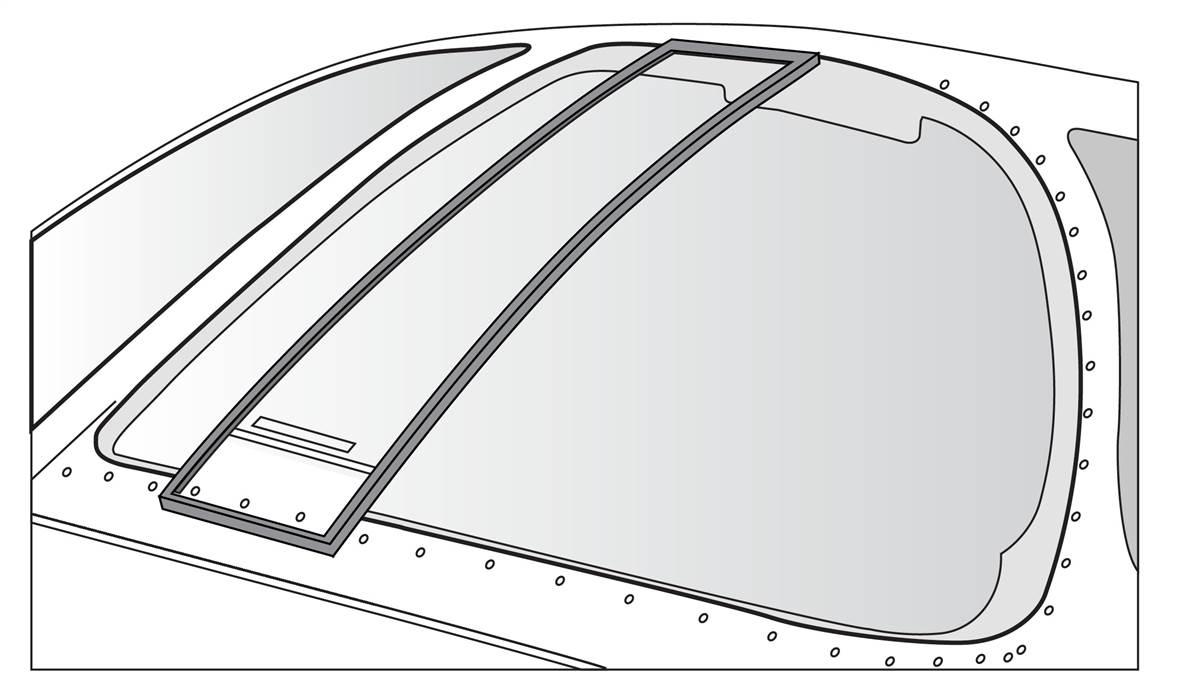

Illustration by Steve Karp

Anti-icing equipment is designed to prevent ice from forming and must be turned on before the aircraft enters icing conditions. Deicing equipment, on the other hand, is designed to remove ice after it begins to accumulate on the aircraft.

There are several ways to fight windshield icing. The most common solution for light general aviation aircraft is known affectionately as the “hot plate,” which is a small, electrically operated rectangular heating element installed on the windshield, usually right in front of the pilot. They can be pretty effective but depending on the conditions may clear only a relatively small area of the windshield.

Another option is a glycol-based system, which employs a mixture of glycol and water against ice. One popular system, called TKS, sprays glycol solution onto the propeller to remove ice; in single-engine aircraft, that fluid then is slung onto the windshield, providing some ice control. Some TKS installations employ a windshield spraybar. Glycol systems can provide either anti-ice or deice capabilities, sometimes both.

Most aircraft powered by turbine engines have much more effective means of keeping the windshield clear. For many, hot bleed air—compressed air drawn from one or more of the turbine engine’s compressor stages (see “Light the Fires,” page 12)—is directed over the windshield. (Bleed air also is used to pressurize, heat, and cool the cabin.) Other turbine aircraft have electrically heated windshields.