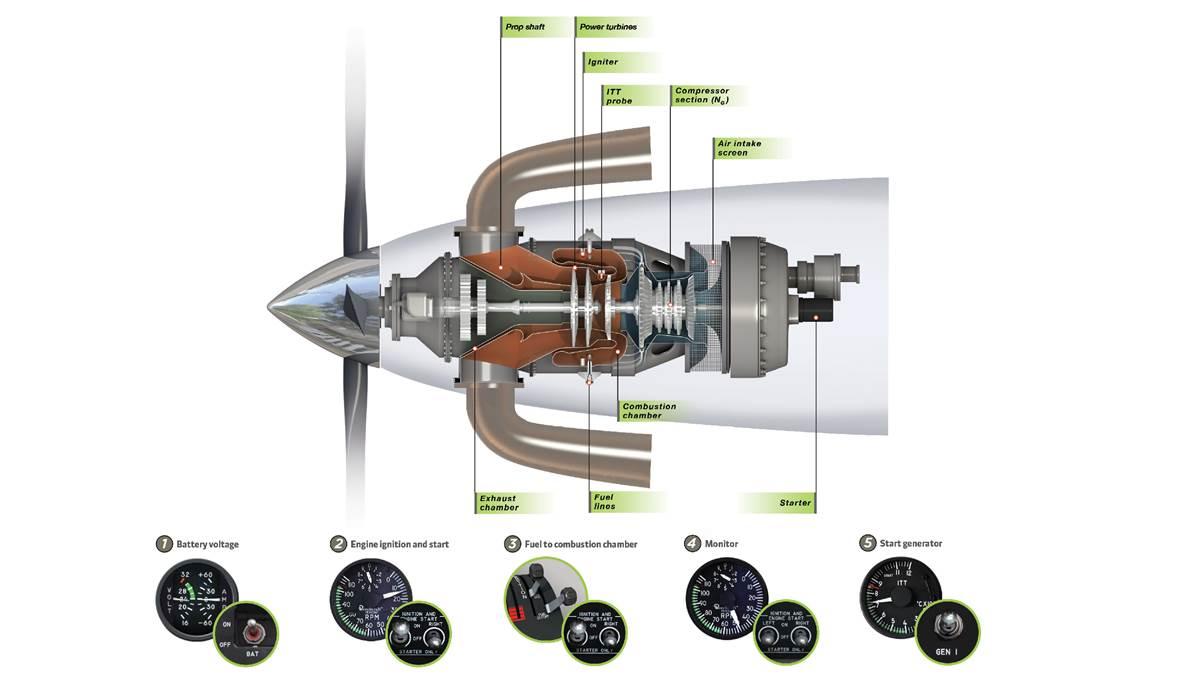

Technique: Light the fires

Starting a turbine engine

In a sense it’s folly to try to explain how to start a turbine engine because each engine and each installation is unique.

Starting a Pratt & Whitney PT6 is different in a Piper M600 than it is in a Daher TBM 930, and a Boeing 737 is different than a Boeing 757.

There are some similarities, however. Like piston engines, turbine engines work on the principle of suck, squeeze, burn, blow. They both take in air, compress it, mix it with fuel to create combustion, and then expel the exhaust. But where starting a piston engine carries little risk to the aircraft’s components, the temperatures and pressures generated inside a turbine engine must be closely monitored, lest they quickly cause major damage.

Illustration By Charles Floyd

- Battery voltage

Battery power on a turbine engine is critical because it must provide enough power to spool the turbine fan blade fast enough to not only draw air in for proper combustion, but also to keep the whole process reasonably cool. Most turbines require around 24 to 25 volts. If the battery doesn’t meet the minimum starting specification, a ground power source must be used. - Engine ignition and start

By pressing a button, turning a knob, or flipping a switch, the start sequence begins. These actions engage the battery with the starter to begin spinning the hot section compressor and N1 fan. Here, the pilot must check to ensure N1 or NG is rising fast enough and ITT, or the interstage turbine temperature, isn’t going too high. If you’re standing outside the aircraft you may hear ticking. Those are the igniters waiting to start the burn process. - Fuel to combustion chamber

Once N1 or NG is beyond a minimum level, fuel is added, usually with a condition lever. Sort of like a fuel on/off switch in what looks like a mixture lever, the condition lever adds fuel, starting the combustion process. - and 5. Monitor and Start generator

Depending on the engine or aircraft the pilot now must monitor everything from N1 or NG to ensure it continues to rise, to ITT to ensure it doesn’t go too high, to oil pressure and temperature, to propeller rpm (in a turboprop). He or she must also turn on the generator if it’s not automatic.

Ian J. Twombly

Former Editor Ian J. Twombly is a professor of aviation at the Community College of Baltimore County and the owner of a Piper J–3 Cub.

Related Articles

Pilot Health and Medical Certification