Opinion: Fortunate catch

A maintenance-aware owneris the last line of defense

His most recent borescope inspection revealed what looked to him like burned exhaust valves in the number 3 and number 4 cylinders. He reported this finding to his local shop, and after verifying his diagnosis a decision was made to send the better cylinder out for overhaul to an engine shop in Tulsa and to replace the worse one with a new Superior Millennium. (I’m not sure whether any consideration was given to lapping the exhaust valves in place—maybe they were too far gone for that.)

His most recent borescope inspection revealed what looked to him like burned exhaust valves in the number 3 and number 4 cylinders. He reported this finding to his local shop, and after verifying his diagnosis a decision was made to send the better cylinder out for overhaul to an engine shop in Tulsa and to replace the worse one with a new Superior Millennium. (I’m not sure whether any consideration was given to lapping the exhaust valves in place—maybe they were too far gone for that.)

The work seemed to be proceeding smoothly. Before long, the shop installed the new and overhauled cylinders and had the airplane almost buttoned back up when Corey stopped by to check on the progress. Informed that the airplane was almost ready for the break-in flight, Corey went over to eyeball his newly installed jugs—and he saw red.

Red stuff

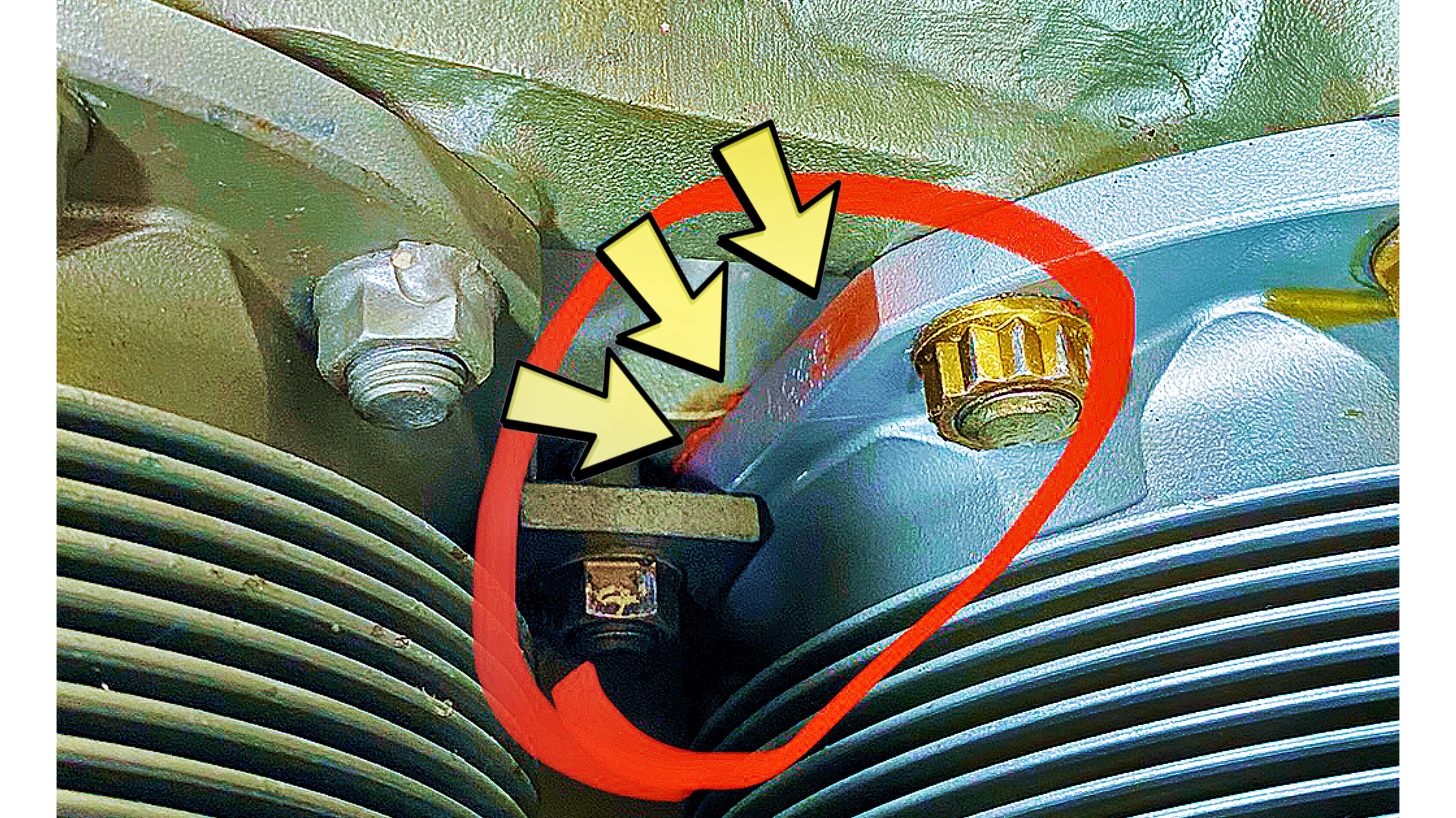

The red he saw was at the base of both cylinders. It was small and subtle enough that most owners would have missed it. But Corey looked at it closely, and it sure looked to him like high-temperature RTV—room temperature vulcanizing silicone rubber.

The red he saw was at the base of both cylinders. It was small and subtle enough that most owners would have missed it. But Corey looked at it closely, and it sure looked to him like high-temperature RTV—room temperature vulcanizing silicone rubber.

A little voice inside Corey’s head was telling him it shouldn’t be there. He had a vague recollection of seeing one of my webinars or reading one of my articles indicating that the use of RTV or other sealants during cylinder installation is an absolute no-no. But he wasn’t sure. So, instead of immediately confronting his mechanic about it, he wanted to make sure he was acting appropriately and wasn’t making a mountain out of a molehill.

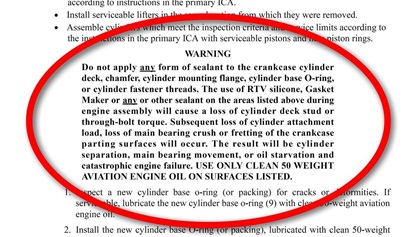

Corey was a subscriber to my company’s consulting service—SavvyQA—so he asked us for a second opinion. Savvy’s technical director Jeff Iskierka, an A&P/IA, confirmed that the use of RTV during cylinder installation could have catastrophic consequences and referred him to the Continental Motors Standard Practice Manual M-0. Corey looked it up and found a forceful warning in boldface type.

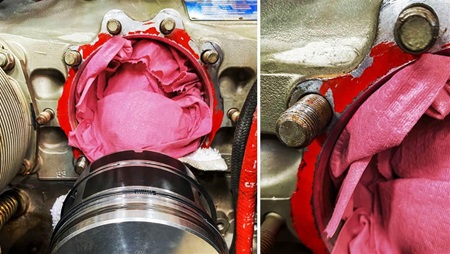

Corey showed this warning to the shop’s director of maintenance, who quickly admitted that they’d made a mistake and would remove the cylinders again to correct it. Once the cylinders were off, Corey was shocked at the quantity of red RTV he saw on the mounting deck area of the crankcase. The mechanic who had installed the cylinders explained that he’d applied some red RTV to the cylinder base seal (O-ring) in hopes that this would help prevent oil leakage, and obviously the RTV had extruded onto the mounting deck area as the cylinder hold-down nuts were torqued.

Corey's experience demonstrates something I’ve been preaching for years: The last line of defense against maintenance-induced failures is an observant and maintenance-aware aircraft owner.Corey made sure that every bit of the RTV was scrubbed from the mounting deck and cylinder base flanges, and that new base seals were used when the cylinders were installed once again.

Backstory

Corey’s vague recollection was of my 2013 article and companion webinar titled “A Little Dab’ll Do Ya…In,” a play on the Brylcreem jingle of the 1950s and 1960s. (Brylcreem was a men’s hair product that came in a tube and resembled sealant.) You might be too young to get that joke—but, trust me, the use of sealant during cylinder installation is no joke.

Corey’s vague recollection was of my 2013 article and companion webinar titled “A Little Dab’ll Do Ya…In,” a play on the Brylcreem jingle of the 1950s and 1960s. (Brylcreem was a men’s hair product that came in a tube and resembled sealant.) You might be too young to get that joke—but, trust me, the use of sealant during cylinder installation is no joke.

The article and webinar described the catastrophic in-flight engine failure and subsequent crash of a 1966 Beechcraft Debonair near Salinas, California. The pilot in command was 32 and a CFI; his passenger was 44. The aircraft was destroyed, and both occupants sustained serious injuries, with the passenger suffering permanently incapacitating brain trauma.

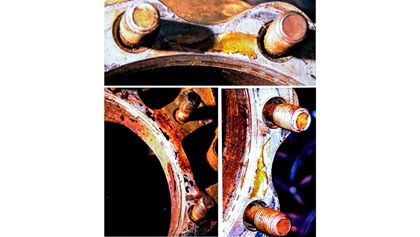

The post-accident engine examination revealed that the number 4 cylinder and piston had departed the engine in flight; they were never recovered. Two cylinder hold-down nuts had backed off their studs. The remaining four studs and both through-bolts were sheared off. The number 4 connecting rod, cap, and rod bolts and nuts were recovered from inside the engine cowling, as were most of the sheared-off studs, through-bolts, and nuts.

The engine logbook entry for the annual inspection conducted 10 months prior to the accident indicated that cylinders 2, 4, 5, and 6 had been removed and replaced with four overhauled cylinders. The NTSB determined the probable cause of the accident to be “the separation of the number 4 engine cylinder due to improperly torqued cylinder hold-down nuts.” As it turned out, that wasn’t entirely correct.

As so often happens after air crashes, the matter ended up in court. The ensuing litigation revealed that there was a whole lot more to this accident than what the NTSB found. The brain-injured passenger sued. Defendants included the PIC, the corporation that owned the Debonair, the repair station that replaced the cylinders, and Continental Motors. The litigation went on for five years, culminating in a jury trial in 2010.

As so often happens after air crashes, the matter ended up in court. The ensuing litigation revealed that there was a whole lot more to this accident than what the NTSB found. The brain-injured passenger sued. Defendants included the PIC, the corporation that owned the Debonair, the repair station that replaced the cylinders, and Continental Motors. The litigation went on for five years, culminating in a jury trial in 2010.

In reviewing the photographs taken during the NTSB’s examination of the engine, the plaintiff’s attorney discovered something crucial that the NTSB investigators missed: multiple dabs of light brown sealant on the mounting deck area of the crankcase where cylinders 2, 4, 5, and 6 were attached. This was the “smoking gun” that explained precisely why the number 4 cylinder departed the engine in-flight.

At trial, the apprentice mechanic who had installed the cylinders admitted to applying a Continental product called “Gasket Maker” to the cylinder base seals. He testified that a Continental tech rep had touted the use of this stuff “anywhere you have a leak,” and that Continental’s written guidance stated that Gasket Maker was appropriate for use on “all uncoated oil seals.” The apprentice mechanic conferred with his supervisor, and both agreed that the cylinder base seal was an uncoated oil seal.

Later in the trial, Continental’s expert testified on cross examination that Continental knew of other incidents where their engines came apart because mechanics had applied Gasket Maker to cylinder base O-rings, yet had not revised its manuals to make it clear that this was not an acceptable use for the product. This convinced the jury that Continental was partially responsible for the accident because they knew of the hazard but failed to issue a warning.

Later in the trial, Continental’s expert testified on cross examination that Continental knew of other incidents where their engines came apart because mechanics had applied Gasket Maker to cylinder base O-rings, yet had not revised its manuals to make it clear that this was not an acceptable use for the product. This convinced the jury that Continental was partially responsible for the accident because they knew of the hazard but failed to issue a warning.

The jury awarded $15 million in damages to the plaintiff, with Continental picking up the lion’s share of the tab. As a result, Continental revised its maintenance manuals to include the aforementioned warning in boldface type.

Read the manual

Honestly, I find it shocking that more than a decade later mechanics in the field are still making the same critical mistake that has caused numerous catastrophic engine failures and put pilots and passengers at risk. In the 1990s, years before I became an A&P myself and was just a maintenance-involved aircraft owner, I was taught by my A&P mentors that the mating surfaces of the crankcase deck and cylinder flange had to be scrupulously clean during cylinder installation. The presence of any contaminant—even paint—could result in loss of fastener preload and cause fatigue failure of hold-down studs and through-bolts, resulting in cylinder separation and catastrophic engine failure. Naturally, I assumed every A&P knew this. Apparently not.

It’s a darn good thing that Corey remembered it, and that he was observant enough to notice those subtle traces of red stuff and recognize what it was. His experience demonstrates something I’ve been preaching for years: The last line of defense against maintenance-induced failures is an observant and maintenance-aware aircraft owner.