Unleaded fuel: What we've learned

AOPA fuel demo Baron at 200 hours

The AOPA unleaded fuel demonstration Beechcraft Baron’s year of flying with two different fuels has come to a close—and we’ve learned a great deal.

AOPA began flying the 1966 Beech C55 in fall of 2023 to demonstrate the efficacy and safety of unleaded fuel in support of a transition to unleaded avgas. It has logged about 200 flight hours using unleaded fuel in the left engine and avgas in the right—and the newly overhauled Continental IO-520s are performing flawlessly. Regular oil analysis, compression checks, and borescope inspections show the engines are healthy and strong, and AOPA has gathered a great deal of engine performance data for detailed analysis and flown the airplane all over the country in all sorts of weather conditions.

The pilots who have flown the AOPA fuel demo Baron have been unanimous that the unleaded fuel used—GAMI G100UL—acts just like avgas in flight. No special techniques are required for engine starts, full-power takeoffs and climbs, cruises, or descents. If the airplane didn’t have decals and placards proclaiming the presence of unleaded fuel in the left engine, pilots would be hard pressed to notice. The FAA authorized use of GAMI G100UL in all spark-ignition airplane engines via supplemental type certificate in 2022, but it is not yet available nationwide. GAMI is currently working to commercialize the fuel.

Both engines pull just as hard during the takeoff roll. In cruise, they run smoothly rich and lean of peak exhaust gas temperature. At the same fuel flows, the G100UL engine has slightly warmer cylinder head temperatures and cooler EGTs, but the differences are negligible. Match the EGTs in cruise and the G100UL engine will consume about half a gallon less per hour than the avgas engine (typically about 12.5 gph compared to 13 gph).

G100UL performs best lean of peak EGT. With both engines consuming G100UL, the Baron’s true airspeed increases 2 to 3 knots with slightly higher CHTs, EGTs, and oil temperatures.

“This strongly suggests that the engines are making more power running lean of peak on G100UL than when both engines are running [avgas],” said Mike Busch, founder of Savvy Aviation, which has analyzed engine data from the AOPA fuel demo Baron. “Since G100UL has a higher energy density than [avgas], it makes perfect sense that the engines are producing a bit more power and a bit greater airspeed on G100UL.”

G100UL has a vastly different chemical composition than avgas, and that’s obvious at the fuel pump. The unleaded fuel looks like apple juice, smells like turpentine—and it has some bothersome traits that avgas doesn’t.

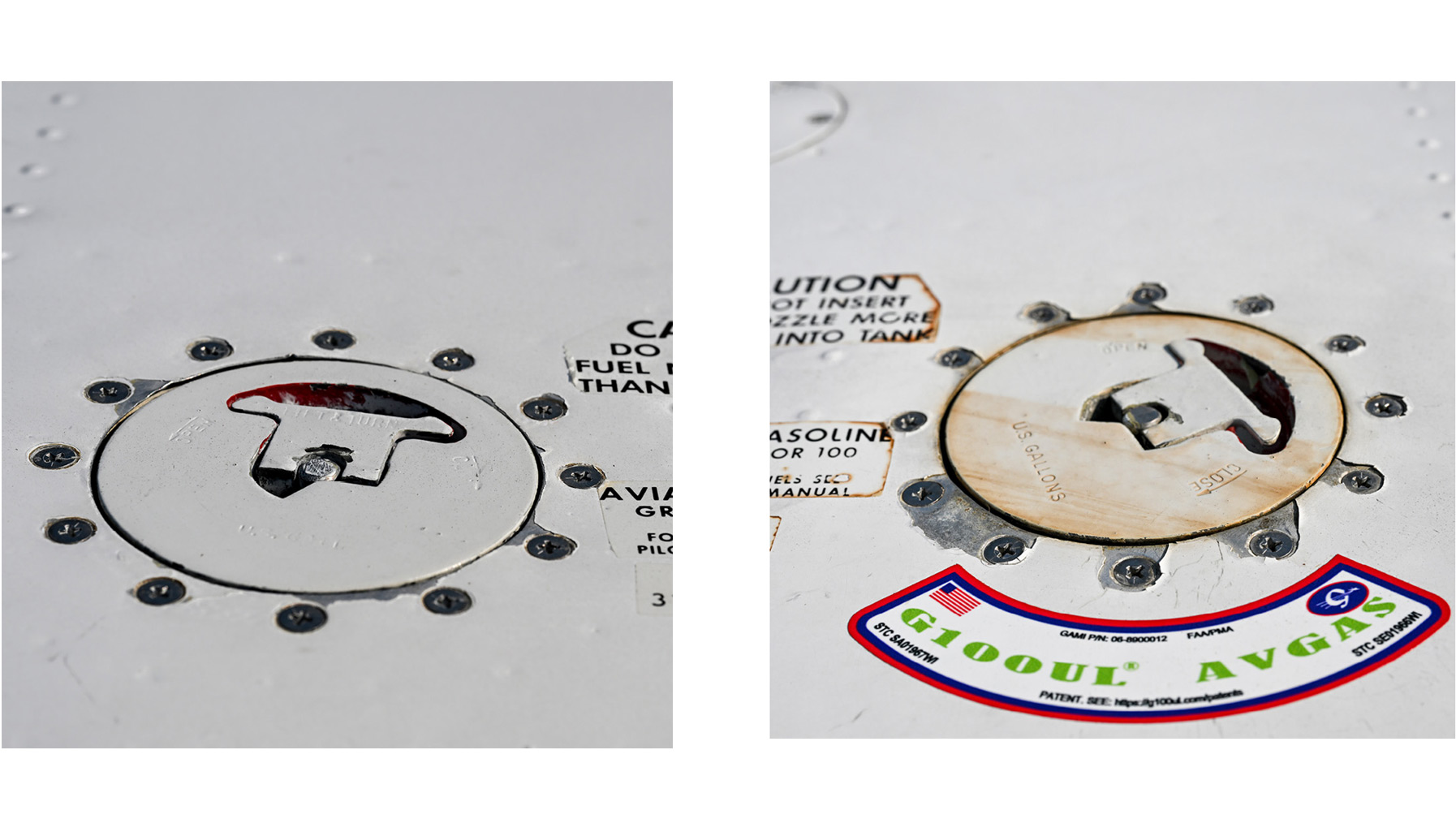

First, G100UL tends to stain paint, hangar floors, and anything else it touches. Pilots and aircraft owners can take precautions by applying protective coatings, but G100UL doesn’t wipe away or evaporate like avgas. Inadvertent and relatively small fuel spills must be cleaned immediately and thoroughly to avoid staining. The top of the fuel caps on the Baron’s left wing have yellowed during its year of exposure to G100UL, while the fuel caps on the right wing show no noticeable change.

George Braly, co-founder of General Aviation Modifications Inc., the Oklahoma firm that developed G100UL, said pilots can avoid paint staining with “good fuel hygiene,” and pretreating aircraft surfaces with ceramic coating and thoroughly wiping away fuel spills right away will avoid stains.

“If the fuel is left on the surface and exposed to the UV from sunlight, then that will cause some brown discoloration,” he said.

Also, G100UL produces black soot that lines exhaust pipes and spark plugs. This fine black ash is easy to wipe away from the exterior. Inside the engine compartment, cleaning the spark plugs with pressurized shop air, for example, blows away the sooty residue immediately.

Braly says the black ash is the product of an excessively rich fuel/air mixture and can be minimized by leaning.

“If pilots do not consistently follow standard good engine management practices with respect to leaning…then there will be accumulations of that black soot in the tailpipe and spark plugs,” he said.

The most important and most vexing question about G100UL is whether it harms other aircraft components it touches such as O-rings, fuel tanks, and fuel lines. GAMI has done extensive tests and says it’s safe. In June, however, Cirrus Aircraft warned customers that it won’t honor warranties for aircraft using G100UL because of concerns about “materials compatibility.”

At EAA AirVenture this year, the AOPA fuel demo Baron unintentionally became part of the debate when leaks from fuel bladders in the left wing stained the ground under the aircraft with a dark puddle of G100UL. There was a great deal of speculation that G100UL may have weakened or destroyed the rubber bladders.

After AirVenture, AOPA had all four bladders from the aircraft removed and inspected by Kurt Hartwig of Eagle Fuel Cells in Wisconsin. Hartwig reviewed aircraft records and pressure tested the bladders. He said the Baron’s main fuel bladders were produced in 1974 and 1978 and overhauled in 2023 before the unleaded fuel demonstration began.

Hartwig found small leaks in both the left main bladder containing G100UL and the right main bladder containing avgas. He didn’t make any determination about why the leaks occurred, or why they were more numerous in the left tank than the right. But he suspects improperly torqued bolts holding the gaskets to the left wing were the main culprit.

“Old cells, under torqued bolts, and unbelievably bad timing led to the leaks and drama at AirVenture,” he said.

All four of the bladders were replaced with newly manufactured ones, and those are made from newer materials resistant to the solvents contained in both G100UL and avgas.

Although this demonstration has reached its conclusion, much work remains to be done. One of AOPA’s highest priorities is working with industry stakeholders to ensure the national availability of an unleaded aviation fuel that works in every piston engine aircraft by 2030. The association remains interested in demonstrating other 100-octane unleaded aviation fuels as they become available.

Thanks to AOPA supporters Greg Herrick and Dan Shewmaker for providing the Baron and allowing AOPA to gain experience with GAMI’s pioneering unleaded aviation fuel.