V-tail Bonanza ruddervator corrosion solved

Minnesota parts maker SRS gains repair approval

V-tail Beechcraft Bonanza owners might mark their calendars and consider July 23 a holiday from now on because a seemingly insurmountable problem with their aircraft appears solved.

During EAA AirVenture Oshkosh in Wisconsin, the American Bonanza Society Air Safety Foundation awarded its $500,000 ASF Manuel Maciel Ruddervator Prize to SRS Aviation of Burnsville, Minnesota, which has committed to manufacture the magnesium replacement skins required for the repair or replacement of ruddervators on V-tail Bonanzas. New replacement skins previously were not available, often resulting in the grounding of aircraft with corroded or damaged ruddervators, which are the control surfaces on the V-tail that move in opposition for yaw and together for pitch.

V-tail owners have long had to contend with the possibility of their aircraft being rendered unairworthy due to even minor corrosion or damage to these surfaces. Of the 10,402 V-tail Bonanzas built between 1947 and 1982, ABS said, more than 5,000 are still flying in the United States, with more in other countries, and all could be affected by the ruddervator problem, which has adversely affected confidence in the full range of Bonanza and Baron models.

The Bonanza group established the prize to encourage manufacturers to come up with an FAA-approved repair or replacement for the damaged parts. The $500,000 award was meant to defray the cost for the first company to design a fix, gain FAA approval, and produce at least 100 repair kits that are ready to install. The group said the actual prize increased to $528,110 with donations from ABS members.

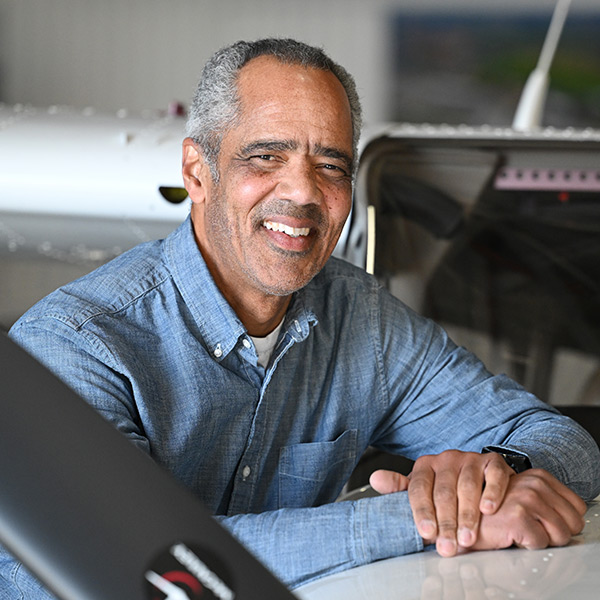

“It was a big challenge to figure out exactly how Beechcraft did it,” said David Laurin, president and owner of SRS Aviation. “The first die we tried cost us $49,000 and we scrapped it. Working with magnesium isn’t easy. When we heard of a V-tailed Bonanza getting parted out because there were no ruddervators available, we knew we had to get in the game.”

More than 5,000 V-tail Bonanzas are currently registered.

“The ASF Board of Directors is proud to award this prize to SRS,” said Susan Delgado, ABS board president. “This achievement was made possible because of the grant from the Maciel family and our ABS member donors. The prize inspired innovation and research within the aviation community, which is critical to address availability of parts for aging airplanes. These new SRS ruddervators will help preserve our Beechcraft fleet for generations to come.”

While SRS has years of experience with aluminum replacement skins for Beechcraft models with conventional tails, “the unique balance requirements of the V-tail could not be met with aluminum,” the group said.

The company put a lot of effort into the ruddervator project, spending more than three years researching magnesium production techniques and developing expertise in working with the material. The company now has FAA parts manufacturer approval for work ranging from skin replacement to complete repair and rebuilding of ruddervators. The change “has restored full confidence in the value and longevity of all models of V-tail Bonanza,” ABS said.

SRS charges $7,150 for ruddervator kits and $9,650 for an exchange.

“In the beginning we thought this was going to be easy to do which could not have been further from the truth,” said Laurin. “First we had a nine-month struggle to PMA this part. Then came the cost of material and manufacture, which included machinery and special processes only related to magnesium. Lastly, there was nobody out there that had special knowledge of how to make formed magnesium parts and specifically how to make them perfectly. With the Manuel Maciel award to offset our development, now we have a really good product and we are confident we can support the fleet for many more years.”

ABS encourages members and others to make tax-deductible donations to the ABS Air Safety Foundation to replenish the Maciel fund to support potential future airworthiness preservation efforts.

—AOPA Pilot Editor at Large Dave Hirschman contributed to this report.