Humidity and corrosion

Keep your engine dry to maximize its life

By Kevin Knight

Rising costs of aluminum, steel, and parts—and a costly Lycoming engine in my Cessna 182 that just passed 2,000 hours since being overhauled—has focused my attention. If positive actions aren’t taken to ensure its long-term health, bad things could happen to my aging powerplant, which costs north of $140,000 new.

Our airplanes operate best when flown frequently. That’s why flight school engines often go well beyond TBO, or time between overhauls, that manufacturers recommend. Continental’s own service manual states: “If an engine consistently accumulates 40 or more hours per month since being placed in service, add 200 hours to recommended TBO.”

Maintenance guru Mike Busch advises keeping an engine on the airplane as long as it’s healthy. Key indicators for assessing fitness are cylinder compression, borescope reviews, oil analysis results, and a careful review of oil filter contents.

Unfortunately, I’m not flying as much as I would like to or should. As a result, my airplane spends too much time sitting in the hangar. Without proper care, corrosion could damage cylinders, piston components, cam shafts, lobes, gears, and anything else made of metal.

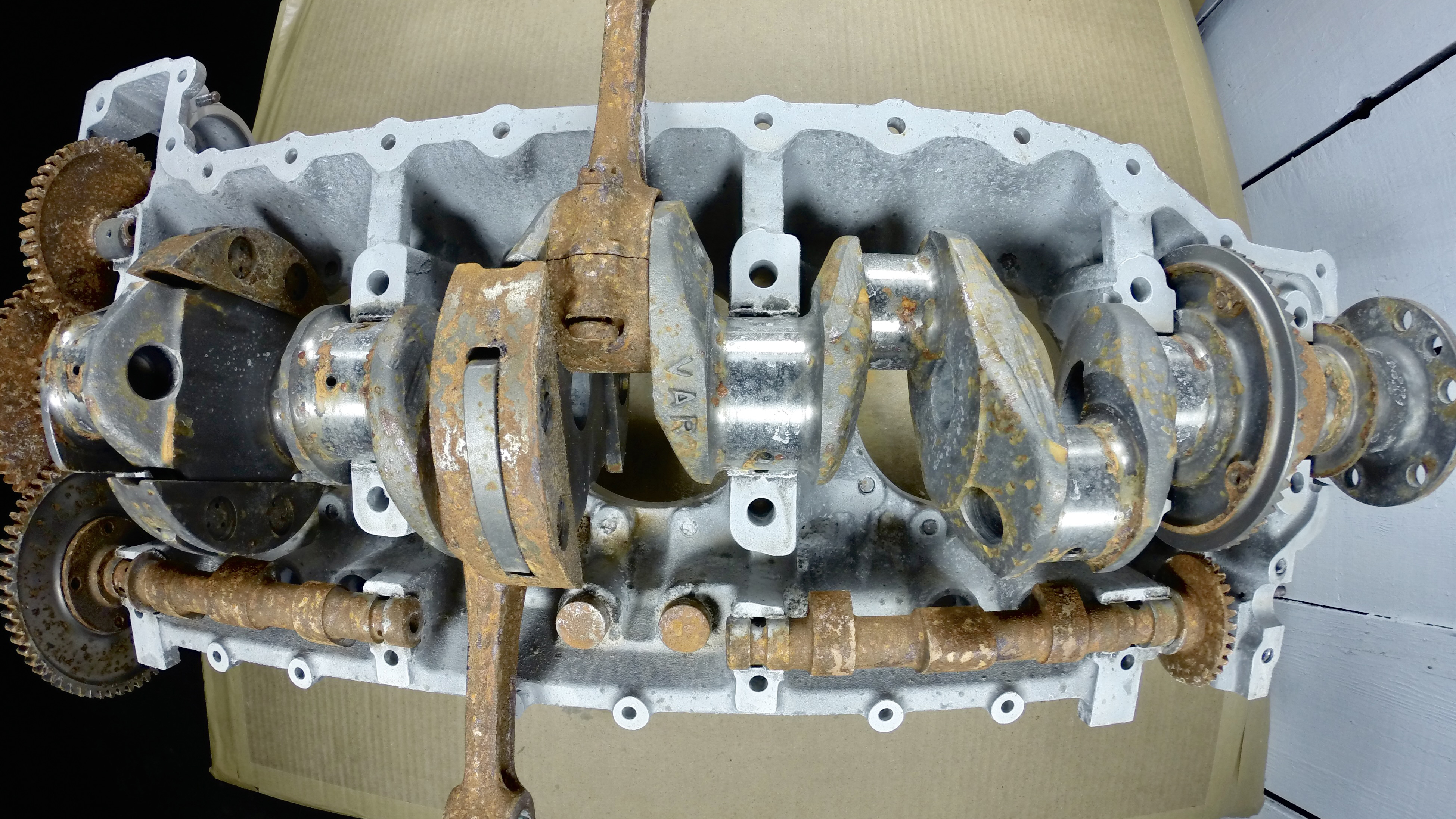

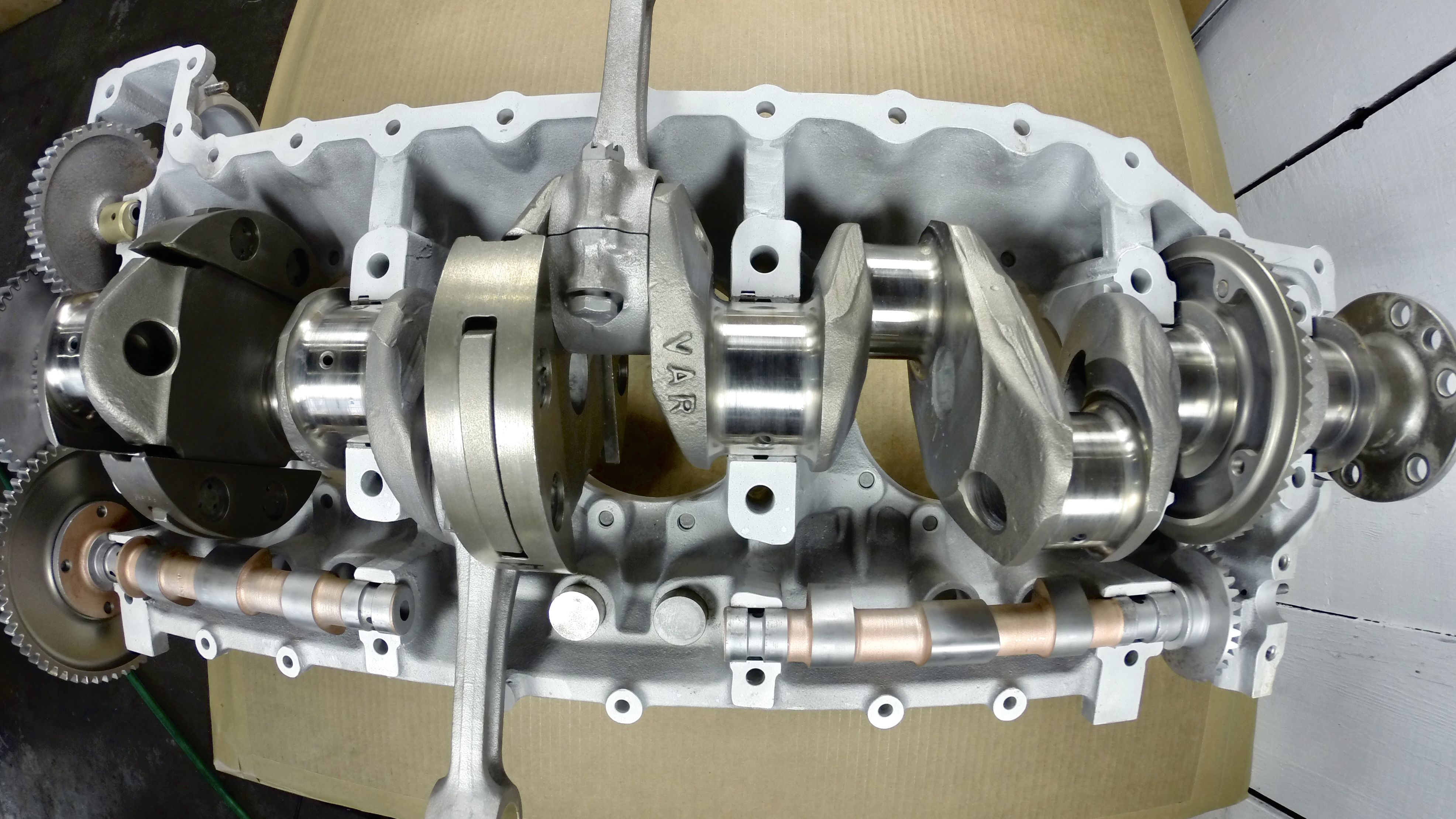

The before/after photos I’ve included from RAM Aircraft show what happened to a pristine engine a few weeks after it was sprayed with a mist of salt water during an experiment. If you’re thinking, “Salt water? That isn’t getting in my engine,” you’re probably right. What is getting in your engine is sulfuric acid. That’s because our engines inhale air for combustion. The water vapor in air combines with sulfur in our fuel and oil, producing corrosive sulfuric acid.

To help reduce engine moisture, oil temperatures must get above 185 degrees Fahrenheit for an hour or so. Running an engine on the ramp for five or 10 minutes just pulls in moisture, creating an acidic sauna. Likewise, pulling the propeller through by hand isn’t good. That wipes protective oil off the cylinder walls, cams, and followers.

What’s rarely discussed is engine humidity, a leading cause of corrosion. The “critical humidity” level required for rust to start forming is 45 percent. If humidity is below that level, ferrous alloys (e.g. steel) and aluminum are much less prone to rust or corrosion.

Lycoming has reported that in high humidity regions, corrosion can start appearing on relatively new cylinders within two days of inactivity. Although experts at RAM Aircraft say rust and corrosion typically wear off when an engine is running, microscopic damage occurs and metals are weaker than before.

For those of us who aren’t flying hundreds of hours annually or living in dry, desert climates, dehumidification is critical. The best ways to do that are by pushing dehydrated air through the engine or keeping the engine warm when it’s hangared.

A friend in Texas who is a certified aviation mechanic initially advised me to use “dehydration” plugs that contain a water-absorbing desiccant when my airplane was down for more than a month. Aircraft Spruce and others sell them for around $20 each to replace the spark plugs. When the desiccant changes color after absorbing moisture, it must be removed from the plugs and heated to 250 degrees Fahrenheit in an oven for 16 hours, then replaced. I did that a few times but concluded it was a poor solution. The desiccant could get saturated many weeks before I returned to my airplane, and removing the cowl to exchange the plugs was a time-consuming hassle.

My friend then built me a dehydrator with an aquarium pump to push dry air through the engine via the oil intake. Before entering the engine, the air had moisture removed with a few pounds of silica gel beads in a plastic case. They would gradually change color as they absorbed more moisture, then have to be baked in an oven to remove the moisture. My wife had no interest in desiccants being dried in “her” oven, and I didn’t want to be a dehydrator maintenance man. That’s when I learned about DryBot in mid-2024.

Less is more

After forsaking dehydration plugs and my homemade dehydrator, I began online research on various engine dehumidifiers. DryBot caught my eye since it was produced by RPX Technologies in Oklahoma, near my hot, humid home state of Texas.

Company co-founder Matthew Dock owns five airplanes and is an A&P with inspection authorization. He also has a master’s degree in mechanical engineering from Oklahoma State University. His academic focus was on metallurgy, with an emphasis on surface finishes, cracks, and other imperfections.

Most of his company’s business is in construction, but his passion for aviation was obvious. His first aviation product was DynaVibe, the market leader in prop-balancing technology.

After earning his private pilot certificate 28 years ago, he got interested in engine corrosion when a cylinder on his Cessna 210 had low compression. There was also a spalled cam lobe and bad lifter faces on the camshaft. The engine shop subsequently split the engine case and discovered the interior “was like a swamp.” Condensation and acidic oil residue pitted accessory gears, through bolts, and other components. The foreman figured someone kept the oil pan heater on all winter, which released lots of moisture into the engine.

Dock initially went down the path I had trod: a “home brew” dehydrator with silica desiccant. However, the humidity afflicting his region quickly saturated the desiccant.

That prompted him to buy an aviation dehydrator online. After installing it on his Cessna 210, he noticed a water droplet going from the device’s clear, plastic tube into his engine. It should have been dry air.

To figure out what was going on inside his engine, he bought some humidity sensors from Amazon. The engine’s internal humidity went down for the first few days of dehydrator use, then started rising. He concluded that was because the device used a cooling plate that couldn’t keep up with Oklahoma’s high humidity. To confirm his conclusions, he did the same experiment using an identical dehydrator and got the same result.

That led Dock and fellow engineer Mike Fox to create DryBot for their airplanes. The shoe-box size device features inflow and outflow monitoring of air, a liquid silica desiccant that extracts moisture from the air before it enters the engine, and automated drying of the desiccant.

Back at RPX Technologies’s factory near Tulsa, controlled studies showed that if humidity in the hangar was 80 percent, the DryBot’s air humidity was less than 20 percent. That’s well below the humidity level required for rust or corrosion formation.

Dock and Fox’s calculations indicated their desiccant could have the moisture automatically removed from it daily for 10 years and still retain 80 percent of its capacity. If that material ever had to be replaced, the factory could do it for $199 (DryBot generates a red LED error code to alert pilots).

The outbound airflow is half-a-liter per minute. Tests with a bank of internal sensors have shown it takes around 15 minutes to purge excess moisture from the engine.

The dry air it pushes into the airplane engine is not recycled back into the DryBot since that would contaminate the desiccant. It exits via the tail pipe or breather tube.

Since my cylinders cost more than $1,600 each and a DryBot sells for $1,200, I viewed it as cheap, long-term insurance and bought one a year ago. I also appreciate that the machine is built in the United States, providing jobs to 25 Oklahomans.

After flights, I push my airplane back in the hangar, remove the oil filler cap, push the DryBot cap with its clear plastic tube on my oil filler hole, and turn it on. Status lights on the top tell me when it’s running and if there are any problems. I haven’t had any, and my recent annual showed cylinder compressions above 75 pounds, perfect borescope results, and no indications of rust or corrosion in my 2,000-plus hours engine.

Kevin Knight is an instrument-rated pilot from Texas who owns and flies a Cessna TR182.

rpxtech.com/drybot.html

rpxtech.com/drybot.html