GE Angel Trumpet video by GE Reports.

A miniature turbojet spooled up on a test bench and expanded the envelope of 3-D printing in a recent experiment by GE Aviation documented by GE Reports.

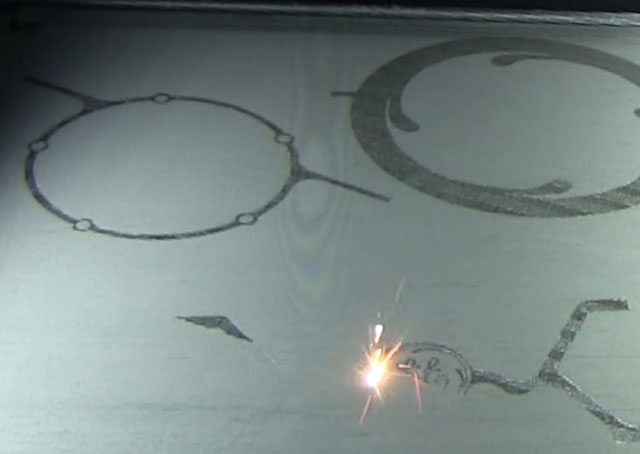

The engine—about the size of a jumbo coffee can, roughly a foot long and eight inches tall—was built with a 3-D printer, though not the sort a hobbyist can buy online. GE Aviation engineer David Bartosik explained the basics in a YouTube video that shows the miniature jet firing up in a GE test facility, after being built layer by layer by a laser that melts metal to form each part.

“We started with a design for a radio-controlled aircraft engine, and improved it to be designed for additive manufacturing,” Bartosik explains, with an implicit don’t-try-this-at-home. The metals used are “high-strength, high-temperature alloys that typically aren’t available for the RC industry.”

The engine at first lit up the lab like a blowtorch, though the flame eventually disappeared as the high-pitched whine increased (engineers dubbed their miniature jet “Angel Trumpet”) and things settled down. A second test fire took those 3-D-printed parts up to 33,000 rpm, with no sign of trouble.

The point of the exercise was not, apparently, to prototype “a jet engine for the Oompa-Loompas,” as Michael Keller described it for GE Reports, but rather to demonstrate the potential for 3-D printing to produce parts able to withstand the forces and temperatures in a turbine environment. One member of the team described it as "a fun side project." The 3-D printing process, at first used strictly to make plastic parts, has evolved into one capable of producing metal parts with the same benefits: less wasted material, and the ability to fabricate highly complex parts in a single piece.

Oompa Loompas are a figment of Roald Dahl’s imagination, of course, though Jetman Yves Rossy is one real-world character who might be interested in testing a tiny turbojet.