The shape of wings to come

After years of development, flexible flaps are said to be ready for the market, while research has produced airfoils even more radical than that in their shape-shifting abilities. An effort to reduce noise and improve efficiency has produced another new take on business jet tails, a u-shaped departure from the status quo that makes for quieter flights, along with a wing that can bend and flex like a bird’s.

Dassault Aviation, maker of Falcon business jets and one of many companies and research organizations collaborating under the Clean Sky initiative, has fitted a Falcon with a radical new tail design, a gull wing that reflects engine noise up and away from the ground. The distinctive tail is one of the more noticeable elements and features incorporated into a vision for future Falcons that also would reduce fuel burn by up to 34 percent compared to Falcon 2000-class aircraft, according to Aviation Week.

The company worked with NASA on the design and prototype testing; the aeronautics and space agency continues to study other variations on wing morphing, including the Spanwise Adaptive Wing project that revisits the design of a 1960s supersonic bomber.

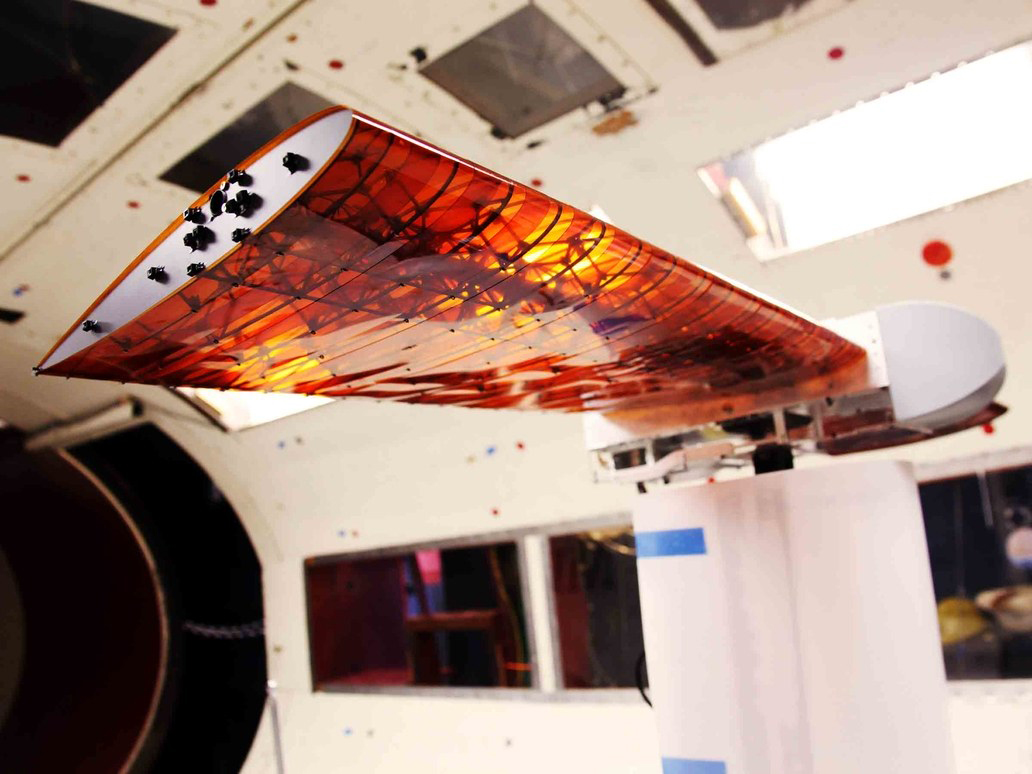

NASA and the Massachusetts Institute of Technology are meanwhile working on an even more flexible wing, one that can change its shape in much the same way a bird’s wing flexes and bends in flight, using just two small motors to control the shape of the entire wing.

Created by assembling small, reusable components that have specific properties and can be arranged into virtually any shape, this flexible wing has passed muster in a wind tunnel, and on a flying scale model.

MIT has even created prototypes of robots that could build each flexible wing, comprised of small structural components arranged in specific geometries that allow for precise adjustments to wing shape and give the wing very high strength at relatively low weight. The benefits, according to the research team, extend to both manufacturing and flight, wings that could be constructed in large quantities in a short time thanks to automation and repaired quickly by robots should components fail. The skin of this futuristic wing is made of overlapping strips of flexible material, “layered somewhat like feathers or fish scales, allowing the pieces to move across each other as the wing flexes, while still providing a smooth outer surface,” the university news office reported. Initial flight tests with an unmanned aircraft proved promising, according to MIT.

“The first tests were done by a certified test pilot, and he found it so responsive that he decided to do some aerobatics,” said graduate student Benjamin Jenett, among several who worked on the project led by Neil Gershenfeld, director of MIT’s Center for Bits and Atoms. Gershenfeld said long-range drones may be the first systems to use the technology, delivering medicines to remote areas.

Observers see potential to scale this building-block approach up to much larger aircraft, and even to build buildings, bridges, and other large structures on the ground, or in space. Wind turbine blades made in this way could conceivably be manufactured on site, on demand, reducing much of the carbon required currently to transport raw materials to factories, and finished products to their final destination.