Introducing the XCub

Speed and range for the backcountry

That’s unheard of—and so is the old-school way the XCub came to be. There are no overseas investors, no venture capital, not even a bank loan. CubCrafters funded the multimillion-dollar project internally because company leaders believe their airplane offers novel attributes in backcountry flying: a high cruise speed, exceptional handling qualities, and unmatched fit and finish.

With a top speed of 153 mph true in level flight, the XCub is about 50 percent faster than a stock Super Cub—and that sort of speed and efficiency means more to backcountry pilots than bragging rights. It gives them operational flexibility in places where headwinds can be powerful and distances between fuel stops vast.

“Our design goals for the XCub included outperforming every other airplane in its category in a meaningful way,” said Jim Richmond, founder of CubCrafters, which has long specialized in improving the original Super Cub design. “We didn’t want an airplane that was a little bit better. It had to be a lot better, across the board. The days of having a Super Cub for fun—and another airplane to actually go places—are over, because the XCub will do both.”

How does the XCub pull this off? Starting at the front, it’s equipped with a 180-horsepower Lycoming O-360-C1G engine and a two-blade Hartzell Trailblazer composite, constant-speed propeller. The streamlined cowl is made from carbon fiber that’s both lighter and stronger than metal, and it’s been engineered for more efficient cooling (and less cooling drag).

The wings have an airfoil similar to that of a stock Super Cub, but the XCub’s rounded, mass-balanced aluminum ailerons provide a crisp feel, and a far quicker roll rate. The ailerons also have blunt trailing edges that give the pilot tactile feedback, and they tend to center themselves in flight.

CubCrafters has been pursuing the contradictory goals of adding strength and decreasing weight, mostly through extensive use of carbon fiber and a simple, light instrument panel. Instead of dozens of small metal pieces in each metal wing rib, for example, an XCub rib is a single stamped part. These ongoing efforts result in a muscular airplane that can carry nearly as much payload as its own empty weight. The only other FAA-certificated backcountry airplane that comes close to matching that feat is the stalwart Cessna 185.

Moving aft, a long dorsal fin runs down the XCub’s back to a rounded tail. The tail looks quite traditional at first blush, but the rudder horn is smaller than that of a stock Super Cub. The higher cruise speed convinced CubCrafters to add a dorsal fin to increase stability, and the rudder counterweight shrank for the same reason.

“A vintage aircraft needs enhanced stability at higher speeds, and the dorsal fin provides that,” said Pat Horgan, head of CubCrafters’ 18-member engineering staff. “We were concerned a dorsal fin would be too prominent and ruin the distinctive lines of the original airplane. But it looks right. The airplane now has a tail that fits its mission.”

A different animal

On the ramp outside the CubCrafters factory in Yakima, Washington, the XCub is striking for its aerodynamically clean lines and gleaming fit and finish.

This airplane, the third XCub the factory has produced, is halfway through an FAA-mandated 50-hour flight test period. During that time it’s limited to one occupant, so CubCrafters President Randy Lervold will stay on the ground rather than coach me from the back seat.

His first bit of advice: Forget all Super Cub preconceptions.

“All Super Cub pilots are aware of the airplanes’ idiosyncrasies,” he said. “The ailerons are heavier than the elevator. They tend to be loud, uncomfortable, and slow. And since so many have been extensively modified, no two fly exactly alike. The XCub is an entirely different animal.”

I step onto the 26-inch tundra tire on the right side of the aircraft, sit on the door frame, and swing my legs into the cockpit. The seat has a commanding view, more Range Rover than sports car, and visibility is exceptional for a tailwheel airplane. I can see forward over the nose, the side windows are cut low for an almost unrestricted downward view, and there’s an expansive skylight overhead.

The VFR instrument panel is quite low. The fuel selector on the left side of the cockpit has positions for Left, Right, and Off (there’s no Both), and the electric fuel pump should be on for takeoff and landing. The flap handle near the left wing root has three detents (16, 33, and 45 degrees). Clear sight gauges in the wing roots display fuel quantity.

Elevator trim is electric and actuated via a grooved rocker switch atop the stick grip. Startup and run-up are normal for a carbureted Lycoming O-360. Lined up with Runway 27 at Yakima’s McAllister Field, full throttle results in brisk acceleration as the prop spins up to 2,700 rpm. With flaps up and neutral elevator, the tailwheel rises off the pavement at about 20 mph, and I hold a tail-low attitude as the mains lift off at about 50.

A 15-degree nose-up attitude at 65 mph indicated results in a 1,500-fpm climb. Only light pressure on the right pedal is needed to keep the slip/skid ball centered. Turning out of the pattern provides the first sampling of the ailerons, and they’re delightfully quick and crisp with a natural self-centering tendency.

I reduce power to 25 inches of manifold pressure and 2,500 rpm, level off at 3,500 feet msl, and let the airplane accelerate. Even with the draggy oversized tires, the airspeed indicator climbs above 130 mph—a number most Super Cubs see only in a dive.

Far different

The makers of backcountry airplanes know every trick when it comes to allowing their specialized aircraft to fly more slowly, and fly on and off impossibly short, rough surfaces.

Tundra tires; tall landing gear; automotive shock absorbers; slatted wings; drooped tips; vortex generators; and long, flat-pitch props allow some models to seemingly defy gravity by landing almost vertically and rolling over rocks the size of bowling balls. CubCrafters takes a different approach with its XCub.

Instead of incremental reductions to an already slow stall speed, CubCrafters transforms this backcountry aircraft by giving it a fast cruise speed and long range. At 120 mph true airspeed, for example, an XCub pilot can cut fuel burn to 6 gph or less and have about eight hours of endurance. At the same time, the XCub retains the Super Cub’s defining slow-flight and short-field capabilities. With flaps down and moderate braking, its landing roll is just 173 feet, and its takeoff roll is 282 feet.

Another defining characteristic of the Super Cub is poor control harmony, a trait pilots have always accepted as part of the airplane’s personality. A certain amount of slop is unavoidable with pulley-actuated ailerons, and pilots have always just dealt with that friction, adverse yaw, and other quirks. Not anymore. The XCub’s ailerons are controlled via push rods for a tight, precise feel.

Outside Yakima’s airspace, I go through some get-acquainted maneuvers. Lazy 8s reveal a finely balanced pitch and roll feel. The airplane is energetic in climb, and its relatively sleek lines allow it to accelerate briskly downhill. Steep turns require an absurdly small amount of airspace, and the expansive view makes maneuvering through this scenery joyful.

Slowing down for a stall series, the chirping aural stall warning comes on at about 50 mph. But with just one person aboard, half fuel, and idle power, I don’t get a stall break. The airplane just descends in a nose-high attitude with the wings level. I add a few inches of manifold pressure, and that increases the pitch attitude and angle of attack enough to get a crisp stall break with slight left-wing drop. Recovery is immediate with relaxation of back-pressure.

Adding flaps via the manual lever at 80 mph (the top of the white arc) produces a noticeable pitch up. The pitch change is much less pronounced at slower speeds, and experienced CubCrafters pilots recommend 70 mph or less for flap deployment.

Flaps-down behavior is unremarkable, but don’t ask me the speed at which a stall occurs. The high AOA makes the airspeed indicator read zero well before the actual break. (For what it’s worth, the GPS groundspeed was 35 mph.)

I drop into Buena Airport for takeoffs and landings on turf. Full flaps and a 55-mph approach result in a tail-low wheel landing. The soft tires and forgiving aluminum gear make the lumpy strip seem fairway smooth. With an 8-knot headwind, I estimate the rollout with moderate braking at 150 feet.

No deposits

The most impressive aspect of the XCub is the way it came to be. CubCrafters self-funded the design all the way through FAA certification. The company hasn’t even collected any deposits from future buyers. Richmond hasn’t polled existing customers about the XCub, either.

“Our customers haven’t been shy about telling us they want a certified airplane with more gross weight,” he said. “I’ve heard it enough times I didn’t need to take a survey.”

Richmond kept the project quiet because he didn’t want to promise his customers an airplane before he knew he could deliver—or jeopardize existing sales. “Aviation is rife with unfulfilled promises,” he said. “I don’t want to be part of that problem.”

With the XCub, CubCrafters introduces a true crossover that retains the Super Cub’s legendary short-field capability and adds speed, payload, range, and superb flying qualities. It takes the Super Cub line as far as it can logically go, given the limits of the current materials and FAA certification.

Backcountry flying has grown steadily in popularity during the past three decades, and the XCub is sure to accelerate that trend. The airplane is at home at airfields large, small, and nonexistent.

The combination of the XCub’s thoughtful design, rugged construction, and attention to detail inspire confidence. Flying the XCub quickly becomes second nature, and the airplane’s benign temperament and outstanding visibility shift the pilot’s attention from the mechanics of operating the aircraft to the wide world beyond the windshield.

The fact that CubCrafters was willing to invest the massive amount of time, effort, and expense in FAA certification—all without a single outside investor—shows that its leaders believe deeply in this airplane and have tied their fates to its future.

Based on the way the XCub performs, they’ve made a safe bet.

Email [email protected]

Testing the XCub

The riskiest part

The topics that test pilot Len Fox was discussing at this morning briefing couldn’t have been more consequential—yet you wouldn’t have known it from his calm, clinical demeanor.

“I’ll initiate each spin at 9,500 feet and recover by 7,500,” he told Pete Dougherty, who would be flying the chase airplane with an observer, and three other members of the flight test team assembled around a whiteboard in a closed Arizona hangar. “If I haven’t recovered by 4,500 feet, call ‘bailout, bailout, bailout’—and don’t hesitate to call it a little early. Too soon is better than too late.”

These instructions weren’t academic for Fox, a former U.S. Navy test pilot who has bailed out of two not-so-perfectly good airplanes.

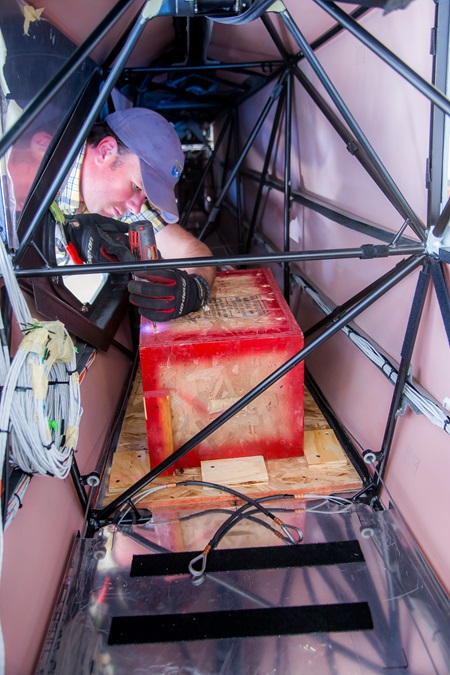

The flight test team was preparing for the riskiest series of spins required for FAA certification in the first fully conforming XCub. The two-seat aircraft was loaded with ballast (a wooden box filled with bags of lead shot) so that the airplane’s center of gravity was at its aft limit—the worst place for spin recovery. Fox would intentionally compound that disadvantage by delaying each recovery and using less-than-ideal technique, as required by FAA certification rules.

Much was on the line for Fox, as well as for CubCrafters. These tests had to go well for the 160-employee company to proceed with XCub manufacturing and sales.

Fox and the rest of the flight test team held to form during the tightly scripted preflight briefing. They covered the weather, which was a brilliant, blue-sky morning in Phoenix, where the team had come for several intensive weeks of out-of-the-way testing. They discussed airspace, alternate airports, and a long series of what-ifs. Dougherty’s chase airplane was equipped with large tires so that it could land off airport in an emergency, and it carried a first-aid kit and water in case he needed to rescue a downed test pilot.

If Fox bailed out or made a forced landing, he would wave with both arms to signal he was uninjured, one arm if minor injuries. (No waving would mean he was unconscious or seriously hurt.) He wore a helmet, parachute, and Nomex flight suit. Fox intended to perform up to 90 spin entries during a pair of two-hour flights that day, a nauseating and ambitious schedule that would conclude the highest-risk part of the tests.

SPEC SHEET

CubCrafters CC19 XCub

Base price: $299,000

Specifications

Powerplant | Lycoming O-360-C1G, 180 hp

Propeller | Hartzell Trailblazer, 2-blade, constant speed

Length | 23 ft 10 in

Height | 8 ft 4 in

Wingspan | 34 ft 4 in

Wing area | 174.8 sq ft

Wing loading | 13.16 lbs/sq ft

Power loading | 12.78 lbs/hp

Seats | 2

Cabin width | 30 in

Cabin height | 52 in

Empty weight | 1,212 lb

Max gross weight | 2,300 lb

Useful load | 1,088 lb

Payload w/full fuel | 812 lb

Payload w/3 hr fuel | 900 lb

Fuel capacity, std | 49 gal (294 lb) 46 gal usable (276 lb usable)

Oil capacity | 8 qt

Baggage capacity | 180 lb

Performance

Takeoff distance, ground roll | 282 ft

Max demonstrated crosswind component | 11 kt

Max level speed, sea level | 153 mph

Cruise speed, 10,000 ft @ 75% power, best economy | 147 mph

Service ceiling | 14,000 ft

Landing distance, ground roll | 173 ft

Limiting and recommended airspeeds

VX (best angle of climb) | 51 KIAS

VY (best rate of climb) | 64 KIAS

VA (design maneuvering) | 86 KIAS at 2,300 lb

VFE (max flap extended) | 70 KIAS

VNO (max structural cruising) | 135 KIAS

VNE (never exceed) | 145 KIAS

VS1 (stall, clean) | 41 KIAS

VSO (stall, in landing configuration) | 40 KIAS

For more information

Contact CubCrafters, 1918 South 16th Avenue, Yakima, Washington 98903, 509-248-9491, www.cubcrafters.com

All specifications are based on manufacturer’s calculations. All performance figures are based on standard day, standard atmosphere, sea level, gross weight conditions unless otherwise noted.

Extra

There’s an option for streamlined Grove aluminum landing gear that reduces drag, adds about 15 miles an hour to the top speed, and—unlike the traditional bungee system—requires no maintenance throughout its service life.

Jacob Varhus, a diligent young CubCrafters engineer, would stay on the ground to monitor the flight online (via flightradar24.com), radio, and SPOT tracker. Perhaps wanting to lighten the seriousness of the moment, one of the other members of the flight test team told Varhus to add a final item to the checklist. “Make sure to brew a fresh pot of coffee before we get back. It’s going to get cold up there.”

Pegasus Airpark near Phoenix is a private residential strip behind two sets of locked gates. It provided an out-of-way, good-weather location for this series of XCub flight tests. The team tried not to draw attention to what it was doing, and kept their hangar’s folding door closed whenever airplanes weren’t coming in or out.

They had been working every day for three weeks to finish the 400-plus required spins and 1,500 test points, and they had put more than 200 flight hours on the two XCubs being tested. One Cub had traditional bungee landing gear, and the other more streamlined Grove spring gear—and data had to be gathered for both.

High-altitude takeoff and landing performance was measured and verified at Show Low Regional Airport (elevation 6,415 feet), and now the spin tests were about to take place over a remote area about 15 miles from the Casa Grande VOR.

In the cluttered hangar, Varhus listened on the radio and watched his computer screen as two blips approached the test area and began maneuvering at 9,500 feet. Then one would quickly lose altitude, and sometimes its radar signature would disappear entirely. “They’re jumping right into the spins,” he said. “They’re not wasting any time.”

About two hours later, the two blips started flying in a straight line back to Pegasus Airpark, and Varhus shut down the computer and started the coffee pot. Folding tables were covered with flight-test detritus: precision measuring and calibration equipment, computers, AA batteries, hand tools, note pads, coffee cups, bags of beef jerky, granola bars, peanut butter, water bottles, and bananas.

About 10 minutes later, the XCubs entered the traffic pattern, landed, and were pushed back into the hangar. The flight-test team assembled around the whiteboard again and all eyes turned to Fox as he reviewed the results.

On the final flight, six spins had developed during 33 potential spin entries, and altering or delaying the recoveries hadn’t changed the character of the spins—even with the center of gravity at its aft limit. Spinning with full nose-up trim didn’t negatively affect the recovery, either.

“There were no exceedances,” Fox said dispassionately. “The test data is acceptable and complete. Spin flights are complete.” —DMH