All Grown Up

Piper updates its storied trainer with a fuel-sipping diesel

We’re in the age of computer-controlled engines, even at the entry level of general aviation. These engines know humans are prone to mistakes and literally have the ability to save us from ourselves. Such is the case with the new Piper Archer DX diesel-powered aircraft.

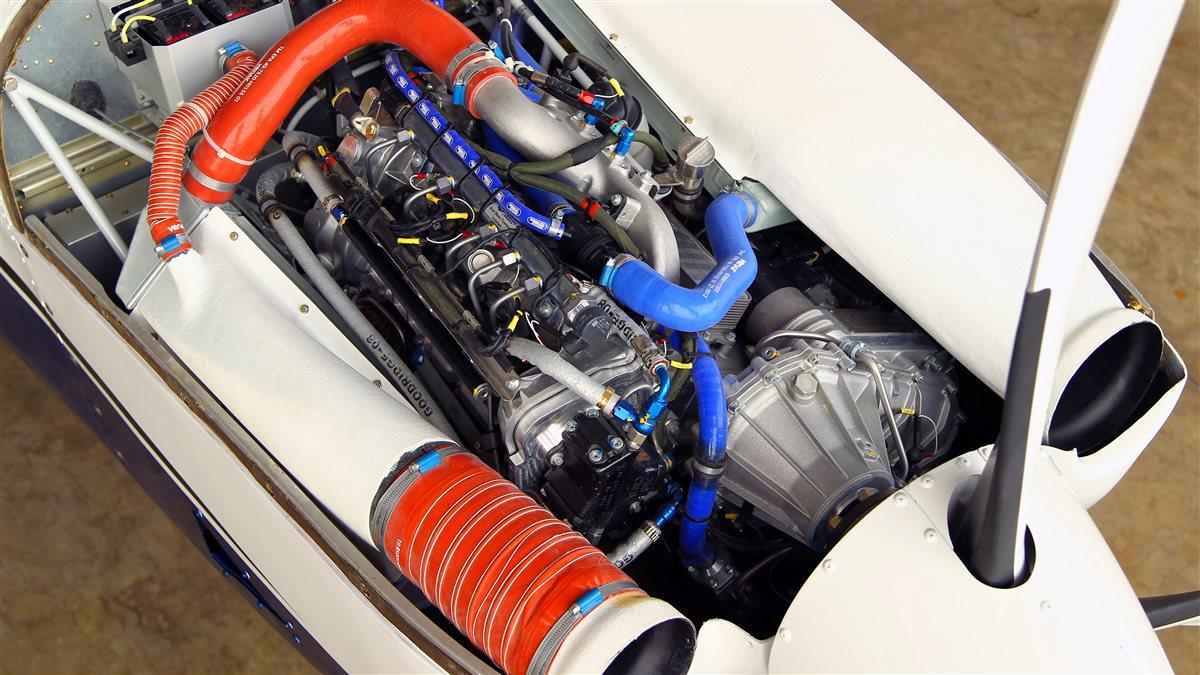

Piper officials entered the diesel-engine market based on the purchase by Continental Motors of Technify Motors, the new name for the German firm Thielert Aircraft Engines. The engine has overcome past problems with a tricky engine clutch, now using something called a dual-mass flywheel to smooth the powerful pulses created by all diesel engines. The Archer airframe has evolved as well, changing to a more efficient wing, and the Garmin G1000 glass cockpit also has matured. All those factors came together to create the 155-horsepower, turbocharged Archer DX. But then the value of the dollar changed, affecting prices in Europe. Piper officials expect currency values will once again be favorable as economic conditions shift.

With the most-often requested options, the price of the $412,000 DX pushes at the $500,000 mark. The cost advantage of the diesel aircraft is clear when 100-octane low-lead fuel costs twice as much as it does in the United States. While that isn’t true in Denmark, 100LL costs four times as much in some African countries. Not only does the jet fuel used in diesel aircraft engines cost less, the CD-155 merely sips at it compared to a thirsty gasoline engine. During a photo flight above the Atlantic Ocean and Florida wetlands near Vero Beach, Florida, it was rare to see fuel usage exceed six gallons per hour.

For most potential customers in the United States, the fuel savings numbers are not enough to influence a buying decision—but the cost savings remains a strong advantage overseas despite the fact that the CD-155 engine must be replaced after 1,200 hours. The replacement costs $40,000, depending on the value of the euro. The old engine is turned in for credit but is not reused or overhauled. As fleet experience grows, Piper officials expect the service time will increase and overhauls will be allowed.

The engine is smooth and quiet, on the ground and in the air. Conversation can be conducted in low tones on the ground and in a normal voice in the air. Vibrations that shake sunscreen visors are not present with a diesel engine, and it’s simple to fly. One lever controls power, fuel/air mixture, and the constant-speed propeller—one control instead of three. You can’t mismanage the power because a computer decides if you are doing something stupid and prevents mistakes such as jamming the throttle forward suddenly. You can’t shock-cool the engine during descent, as with a typical air-cooled engine, because the diesel is liquid-cooled. Disadvantages include the 80-pound weight penalty of the engine compared to a gasoline engine, and the upgrade cost of nearly $60,000.

“The difference in price due to the diesel engine is made up for in a couple of years in places where avgas is twice as expensive as jet fuel, such as Europe,” Piper Technical Sales Manager David Athay said. With all that extra weight out front, batteries were shifted rearward to keep the same in-flight load balance as with the avgas-powered Archer. During a cruise speed check flown at 75-percent power, the DX turned in 113 knots true airspeed at 4,500 feet (a density altitude of 5,768 feet) on a hot Florida day with a full load of 48 gallons of usable fuel. Fuel flow was 5.7 gallons per hour.

There is one big caveat to a FADEC engine; it needs electrical power to continue to run. There are no spark plugs and no magnetos that—in a gasoline engine—continue to provide electricity to the spark plugs as long as the engine runs. The fuel/air mixture in a diesel engine ignites because the cylinder compresses it, not because it is torched by a spark plug. (It’s also called a compression-ignition engine.) Should both the main battery and alternator fail, the engine runs on emergency battery power for 30 minutes—twice as long if you turn off as many electrical devices as possible, but you need to get on the ground. The operating manual understandably advises keeping a close eye on the health of the alternator.

Athay said Piper officials are especially proud of the integration of the engine with the Garmin G1000 avionics system. Except for three lines of the engine information column on the multifunction display, it looks no different from any other G1000 system. Power is reported as a percentage, meaning you needn’t look in the operating manual to see what engine speed equals the desired power setting. There is a line reporting gearbox temperature, and another reporting fuel temperature. The gearbox feeds power to the propeller. During a climb after our formation flight, the gearbox temperature rose to the caution range, meaning that I needed to reduce power and climb at 90 knots indicated airspeed rather than 76—the speed for the best rate of climb—for better cooling. It was a hot, humid Florida morning even prior to 8 a.m. For extended climbs Piper recommends 87 knots indicated airspeed. With that speed and reduced power to keep the gearbox happy, I saw a 400-foot-per-minute climb. That said, the turbocharger does provide full power for a climb to nearly 10,000 feet, while a nonturbocharged engine slowly loses horsepower as altitude increases.

What I first noticed about the airplane—other than the strip lighting above the instrument panel that was greatly appreciated on our early-morning flight—was its stability. That’s a testament to the long development life of the Archer that has incorporated decades of improvements.

Spec sheet

Piper Archer DX

Base price: $412,645

Price as tested: $473,590

Specifications

Powerplant 155 horsepower turbocharged TAE 125-02-114

Recommended time between replacement 1,200 hr

Propeller constant-speed 75-inch diameter 3-blade MT Propeller

Empty weight, as tested 1,846 lb

Max gross weight 2,550 lb

Useful load, as tested 704 lb

Payload w/full fuel, as tested 383 lb

Fuel capacity 50 gal (48 gal usable) 335 lb (321 lb usable)

Performance

Takeoff distance, ground roll 919 ft

Takeoff distance over 50-ft obstacle 1,673 ft

Rate of climb, sea level 683 fpm

Cruise speed/endurance w/45-min reserve,

(fuel consumption) @ 75% power, best economy 115 kt/5 hr

6,000 ft (42 pph/6.3 gph)

Max operating altitude 16,400 ft

Service ceiling 16,000 ft

Landing distance over 50-ft obstacle 1,400 ft

Landing distance, ground roll 920 ft

Why this one costs more

The Piper DX reviewed for this article has several options including: the Genesys S-Tec 55X autopilot for $34,000, a BendixKing ADF at $7,160, a BendixKing KN63 DME costing $8,850, Jeppesen ChartView at $3,695, and metallic bottom basecoat paint at $6,825. Also, it is the Archer LX high-end model. A trainer-level Archer would be $12,600 less.

Cool factor

Strip lighting under the glareshield is airliner-like.

Summer dog days

The diesel engine can’t power an air conditioner compressor, but if you need it and buy a fleet of DX aircraft, Piper engineers will install an electric air conditioner.

Since the air was smooth we were able to descend at 141 knots true airspeed back to Vero Beach and 30 percent power, with a fuel flow of 2.7 gallons per hour. I mentally ran through the standard GUMPS checklist. Gas: We are on the fullest tank and the fuel pump is on. Undercarriage: The landing gear was never up. Mixture control: Don’t have one. Prop control: Don’t have one. Seatbelts: Got those and they are latched.

I wondered if there would be nose heaviness during the landing as I raised the nose just above the runway to land on the main gear first. There was none, indicating that the extra weight of the diesel engine was well counterbalanced by moving batteries aft.

It’s hard not to agree with Piper’s Athay that a very mature airframe and avionics system has been joined by a now-mature diesel engine. The result will turn lots of heads in the training market, especially once the ever-changing value of the dollar makes this a good buy for European customers.

It doesn’t haul a lot when fully fueled, so the answer is to fly partially fueled. You can carry two 200-pound people and baggage, fly for nearly four hours, and still land with an hour of reserve fuel as suggested by the AOPA Air Safety Institute.

Customers pay for the Technify supplemental type certificate through Piper as part of the total cost. Everything about operating a computer-controlled engine, known as full authority digital engine control (FADEC), is simpler than a comparable gasoline engine. It is critical to test FADEC systems A and B (think B for backup) before takeoff, but your role is just to hold a button down while the computer completes the test. It will increase engine speed, reduce it, and take measurements while you watch.