Training Savvy A&Ps

Bringing GA maintenance into the twenty-first century

A&Ps are born with an itch to take things apart. That’s what drew us to aircraft maintenance in the first place. Airplanes are cool and complicated machines, and it’s hard to resist the temptation to disassemble and dissect them to learn how they work. Putting them back together again is almost as satisfying. Almost.

I’ve long been struck by the close parallels between aircraft maintenance and medicine. Both doctors and mechanics devote themselves to troubleshooting and repair of extremely complex machines, and their work involves life-or-death consequences. Doctors, however, are bound to the Hippocratic Oath to “first, do no harm.” A&Ps don’t take such a pledge. Maybe we should.

The world of maintenance for small GA airplanes is still stuck in the 1950s. Most GA shops and mechanics operate with the same philosophy and habits they did in the Eisenhower era: pull cylinders for weak compression, overhaul engines and props at arbitrary times between overhaul, and treat manufacturer maintenance schedules as if they were handed down on stone tablets.

Meanwhile, airlines, the military, and big bizjets have moved on, adopting modern maintenance philosophies built on data-driven diagnosis, on-condition preventive maintenance, and minimally invasive inspection and repair techniques. They endeavor to do just enough maintenance to make the aircraft safe and reliable, understanding that doing too much maintenance can be worse than not doing enough.

Small GA has been left behind. That’s why my company, Savvy Aviation, created Savvy for Shops, our new initiative to help drag GA maintenance into the twenty-first century. It’s a three-pronged effort.

First, there’s ShopTalk, our free online community for GA mechanics to share ideas, problems, solutions, opinions, sources of parts, employment opportunities, and hangar wisdom with one another. Savvy has had this kind of in-house chat room for more than a decade, where our team of more than 40 veteran A&P mechanics with inspection authorization, analysts, and subject matter specialists ask questions, request second opinions, get troubleshooting ideas, and create team cohesiveness. With the launch of ShopTalk, we have expanded this online inner circle to participation by GA maintenance professionals, trainees, and students worldwide. Career aircraft mechanics are welcome to join the group at community.savvyaviation.com.

Second, there’s a new consulting service for shops that we call Powered by Savvy. It gives participating shops access to Savvy’s brain trust of veteran IAs, analysts, engine builders, avionics technicians, and other subject matter specialists, and is modeled after Savvy’s successful SavvyQA consulting program for aircraft owners. It’s like having a roomful of maintenance experts on speed dial.

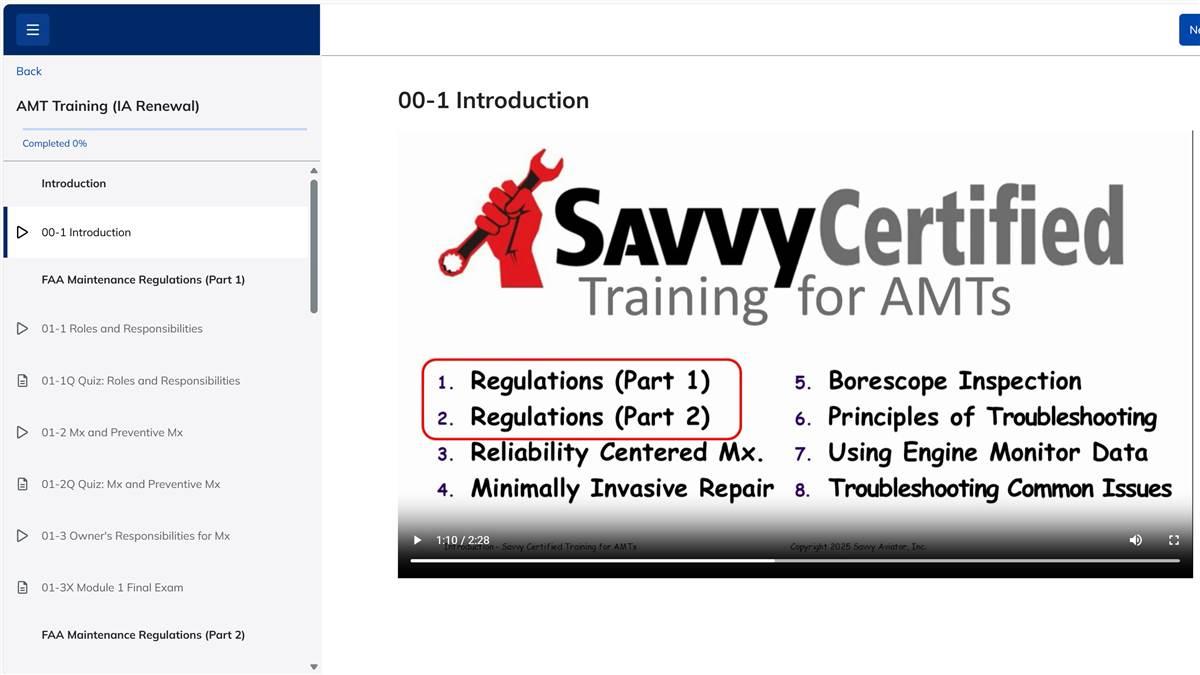

Third, and perhaps most important, there’s Savvy Certified AMT Training, our new online course for A&Ps and IAs, aimed at teaching both experienced mechanics and newbies the latest methods and best practices for doing maintenance like the big boys.

IAs are required to meet certain FAA requirements each year to maintain their inspection authorizations. They can do a certain number of inspections, major repairs, or alterations. However, most choose to take eight hours of IA refresher training each year, similar to how doctors take continuing medical education each year to maintain their board certifications. Most IAs take this training online.

So, we figured if IAs have to take eight hours of annual training, they might as well spend the time learning something new. That’s the idea behind Savvy Certified AMT Training. It’s free and online, accessible from any device—even a smartphone—and it’s FAA-blessed for IA renewal credit. The course presently consists of eight hour-long modules, each consisting of a series of video training segments interspersed with short quizzes and ending with a final exam. The quizzes and exams are learning opportunities, not assessments, allowing wrong answers to be corrected.

The rules of the game

Every FAA-accepted IA renewal course needs to cover the regulations related to maintenance. There are roughly 30 rules that every maintainer needs to be familiar with. The first hour of the course focuses mostly on the Part 91 rules that speak to aircraft owners, and the second hour on the Part 43 and 65 rules that speak to maintainers.

However, most of these first two hours is spent telling “the rest of the story.” Why are these regs worded the way they are? What do they really mean? How are their meanings affected by FAA policies and legal interpretations? For instance, what exactly is “preventive maintenance” in light of the 2009 Coleal interpretation? What does it mean for a maintenance method, technique, or practice to be “acceptable to the administrator”? What does “airworthy” mean? Stuff like that.

Perhaps most important, this section of the course explains the division of responsibility and authority between aircraft owners and mechanics. It discusses the essential partnership between owners and maintainers, what causes this partnership to go off the rails sometimes, and how to ensure it works as smoothly as possible.

Reliability-centered maintenance

Hour 3 is devoted to reliability-centered maintenance (RCM), the science of how to do just enough maintenance to make an aircraft safe, reliable, and legal, while not doing so much that it degrades safety through maintenance-induced failures. RCM was first developed in the late 1960s at United Airlines, where it turned traditional thinking about maintenance on its head. United scientists Stan Nowlan and Howard Heap discovered that very few mechanical failures happen because components become old and worn out. Instead, the lion’s share of failures occur when components are young, not old, or when systems that are working fine are messed with unnecessarily.

The findings suggest that the traditional practice of overhauling components at a fixed time between overhauls or replacing them at a fixed life limit actually makes the aircraft less safe and reliable. They also suggest that taking things apart to inspect them on a fixed timetable could do more harm than good. RCM researchers amassed a huge body of evidence that lends credence to the old saying, “If it ain’t broke, don’t fix it.” Unfortunately, much of the scheduled maintenance called for by most manufacturers turns out to be more like, “If it ain’t broke, fix it until it is.” Fortunately, the FAA doesn’t require us to follow most of this guidance, and we shouldn’t.

Minimally invasive methods

The next two hours provide detailed “how-to” instructions for some of the most important modern methods for cylinder inspection and repair. The traditional standard of care is to do a compression test at each annual inspection, and cylinders exhibiting weak compression are removed and sent out for repair or overhaul. This is the equivalent of checking a patient’s heart with a stethoscope and performing open-heart surgery if an arrhythmia is detected. Cylinder removal is both maximally invasive and unnecessarily risky.

A pair of minimally invasive methods address the two most common causes of weak compression. If the weak compression is due to leakage past the exhaust valve, lapping the valve in place will usually solve the leakage and dramatically improve compression readings. If the issue is leakage past the rings, a simple solvent ring flush can work wonders, freeing up stuck rings and reducing oil consumption and spark plug fouling. Both methods eliminate the need for cylinder removal.

Hour 5 teaches an important skill that isn’t covered in A&P school: how to perform a proper borescope inspection of a cylinder. It describes the 11 images that need to be captured in a specific order for each cylinder and demonstrates exactly how to position the scope to obtain each one. These images can be uploaded to Savvy’s cloud-based image repository, tagged, analyzed, annotated, archived, and reported.

Data-driven troubleshooting

The last three hours of the course are devoted to troubleshooting, the special aspect of aircraft maintenance that is accomplished purely with headwork, not handwork. Working with hundreds of shops and thousands of mechanics over the past 17 years, we’ve found that troubleshooting is one of the weakest areas for most A&Ps. Some A&Ps are troubleshooting superstars, but they’re few and far between. We need to do a lot better.

When faced with an aircraft system that isn’t working properly, the urge to find out what’s wrong by taking it apart can be powerful. Mechanics need to resist that urge. The key to diagnosing a problem accurately is to gather as much data as possible, preferably by noninvasive means. This is best accomplished using tools like borescopes, multi-meters, lab reports, and engine monitor data—not wrenches, screwdrivers, and other implements of destruction.

The course takes a deep dive into the methodology of “differential diagnosis” that every doctor is taught to use in medical school but few mechanics are taught in A&P school. In a nutshell, this involves making a list of everything that could possibly be wrong with the malfunctioning component or system, then going through the list and ruling out any possible causes that are inconsistent with the symptoms and diagnostic data. With luck, only one possible cause will survive, and that’s the definitive diagnosis. If more than one possibility remains, then additional tests are performed and data gathered to rule various possible causes in or out.

Analysis of digital engine monitor data is one of the most powerful tools we have for diagnosing engine problems. The power comes from engine monitor data analysis, uniquely showing in exquisite detail what the engine is doing when it’s running. It’s totally noninvasive. This skill is not taught in A&P school and is hardly ever utilized by mechanics in the field. We hope to change that.

Finally, the course offers a satchel full of tips and tricks for diagnosing common engine and electrical problems: things like rough-running, hard starting, high cylinder head temperatures and exhaust gas temperatures, low oil pressure, charging failures, high or low bus voltage, headset whine, circuit breaker trips, and more.

Changing the culture

This new AMT training course isn’t just about state-of-the-art methods—it’s about culture. For too long, GA maintenance has been mired in tradition, habit, and a blind faith in OEM guidance. Our hope is that Savvy Certified mechanics and shops will adhere to a higher standard—one built on evidence, data, and techniques that minimize risk and cost while keeping aircraft safe, reliable, and legal.

savvyaviation.com

savvyaviation.com